Method for preparing calcium group carbonic anhydride adsorption agent

A calcium-based adsorbent and carbon dioxide technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of reduced capacity, reactor wear, increased fouling and corrosion, and increased operating costs, so as to reduce abrasion and improve Anti-sintering performance and the ability to capture CO2 cyclically, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

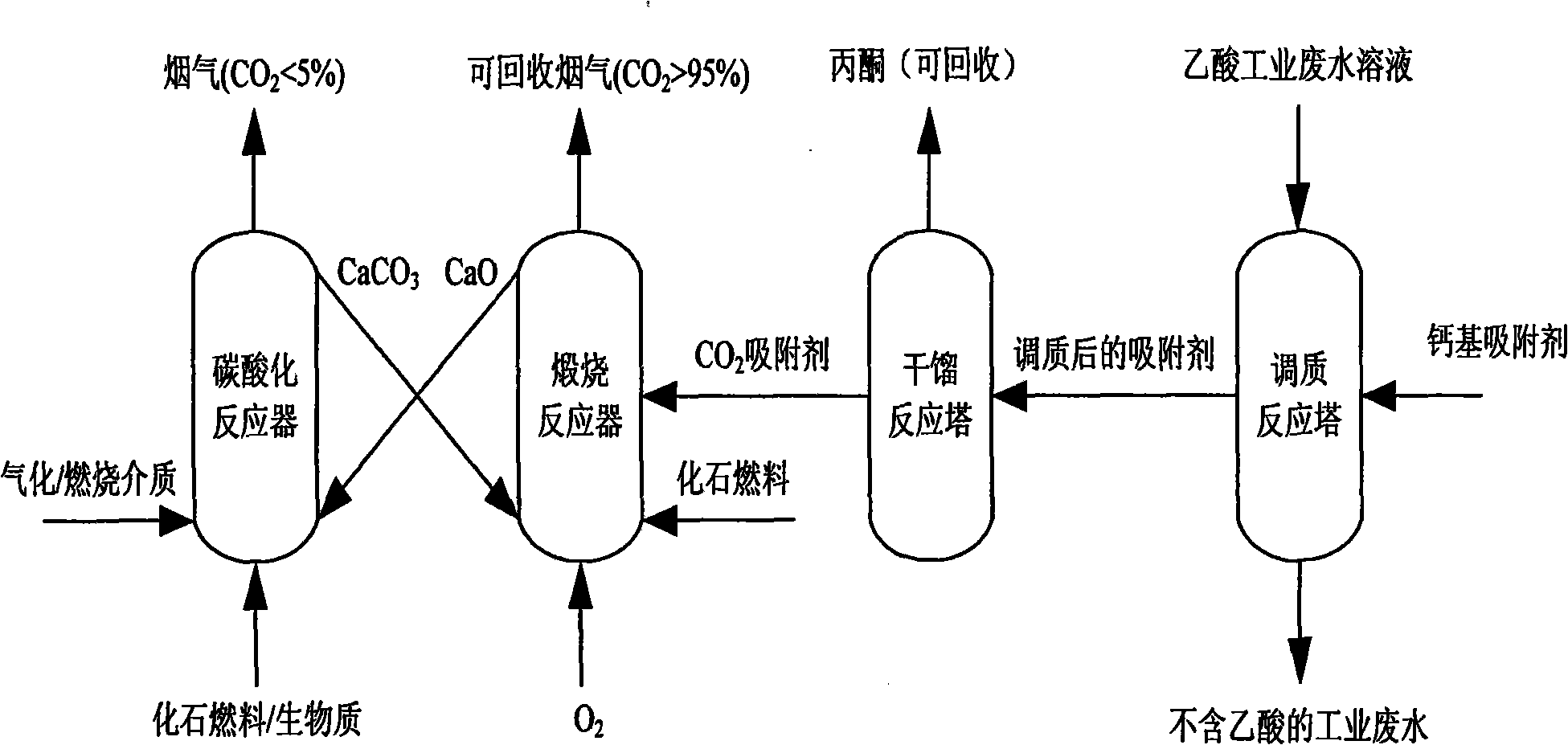

[0015] figure 2 It is a process flow chart of using acetic acid wastewater to condition calcium-based adsorbents in the cyclic calcination / carbonation process. The calcium-based adsorbent enters the conditioning reaction tower and undergoes acidification reaction with the acetic acid wastewater. After conditioning, the adsorbent enters the dry distillation reaction tower for carbonization, recovers the acetone released by the conditioning adsorbent, and then undergoes calcination / carbonation reaction cycle capture CO 2 .

[0016] The specific operation method of using acetic acid wastewater to condition the calcium-based adsorbent is as follows: under normal temperature and pressure conditions, the acetic acid wastewater solution is placed in a container, and calcium-based adsorbent particles such as limestone, dolomite and calcium oxide are added to the acetic acid wastewater During the reaction, stir while adding, the molar ratio of acetic acid in the acetic acid wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com