Plastic mold steel and method for manufacturing same

A technology of plastic mold steel and manufacturing method, applied in the field of plastic mold steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

0.97

[0037] Note: No Cu was added in the 0# embodiment, which is only used as a comparison.

[0038] Heating to 1180-1200°C, holding time for at least 2 hours before forging, the initial forging temperature is 1050-1100°C, and the final forging temperature is 900-950°C. Finally, it is forged into Φ85mm and Φ20mm bars for performance testing.

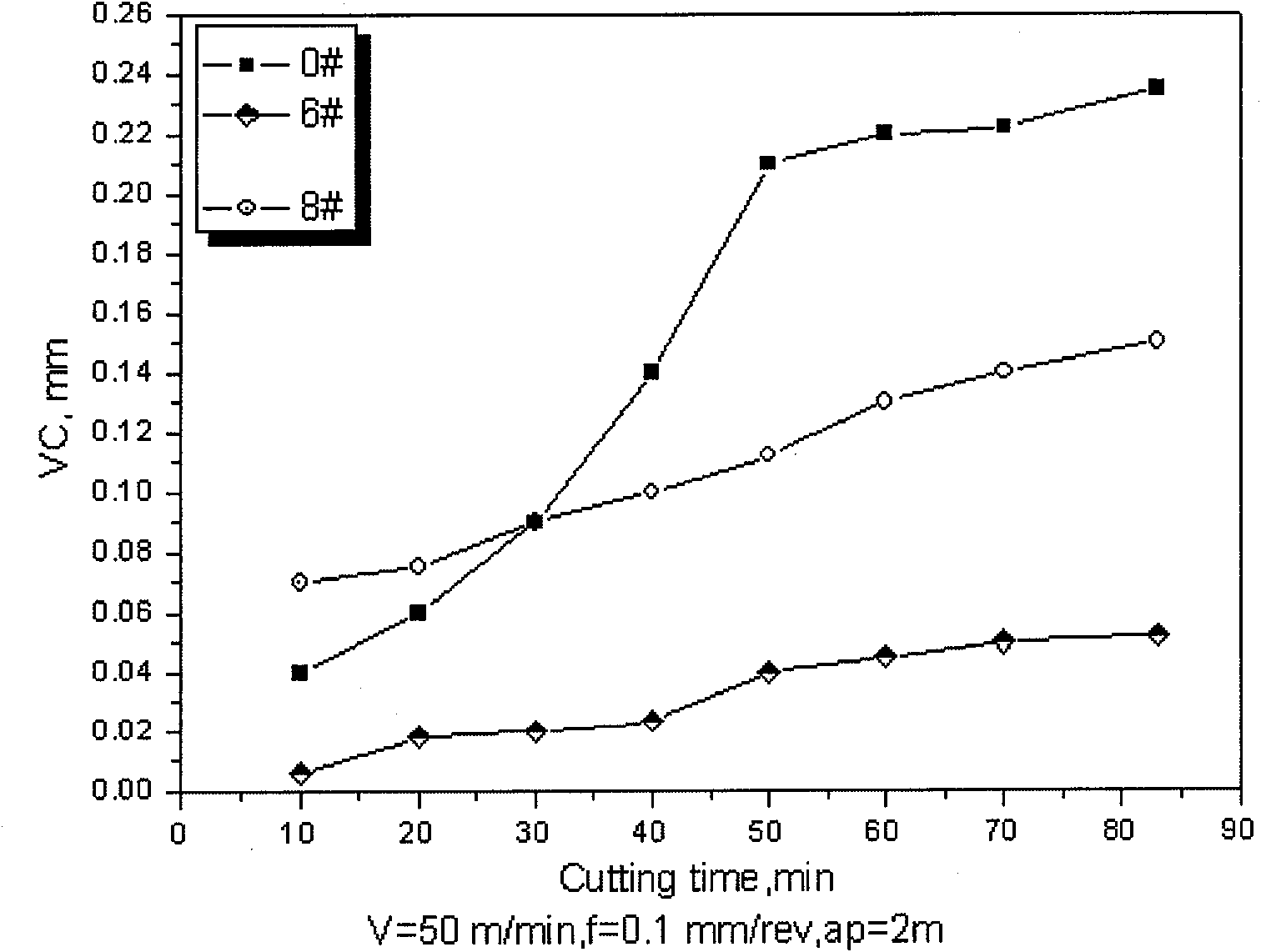

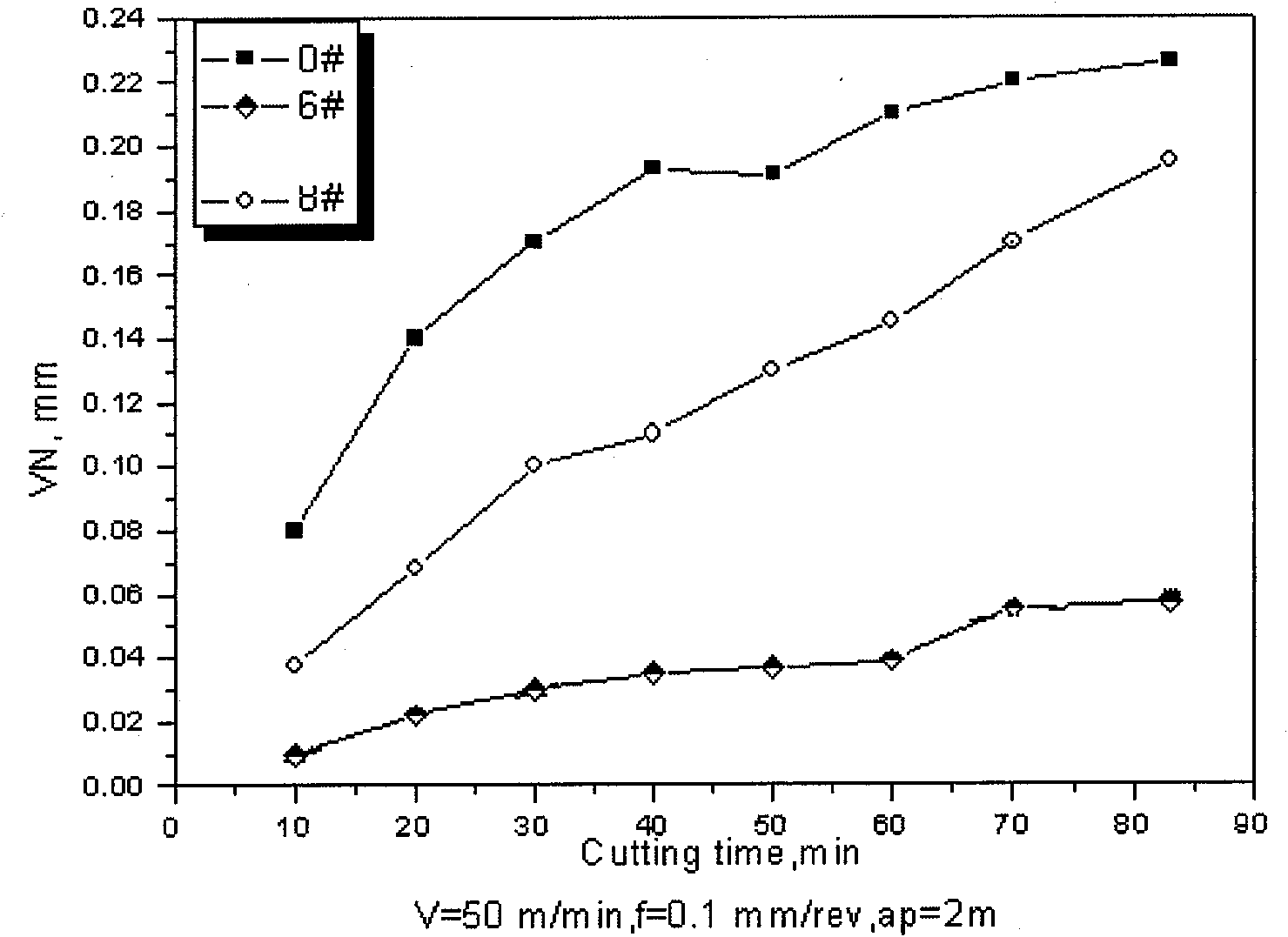

[0039] The cutting test was carried out on a C6140 machine tool using dry cutting. The cutting tool was made of YT15 carbide cutting tool, and the rake angle, back angle and leading angle of the cutting tool were all 75 degrees. The cutting conditions are: the feed rate is 0.1 mm / rev, and the cutting speed is 50 m / min. During the test, the tool nose wear and the maximum flank wear were measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com