Combined interference device for aspheric surface measurement

A measuring device and aspheric technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult to change fringe frequency, difficult to realize real-time dynamic measurement, and impossible to measure aspheric surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

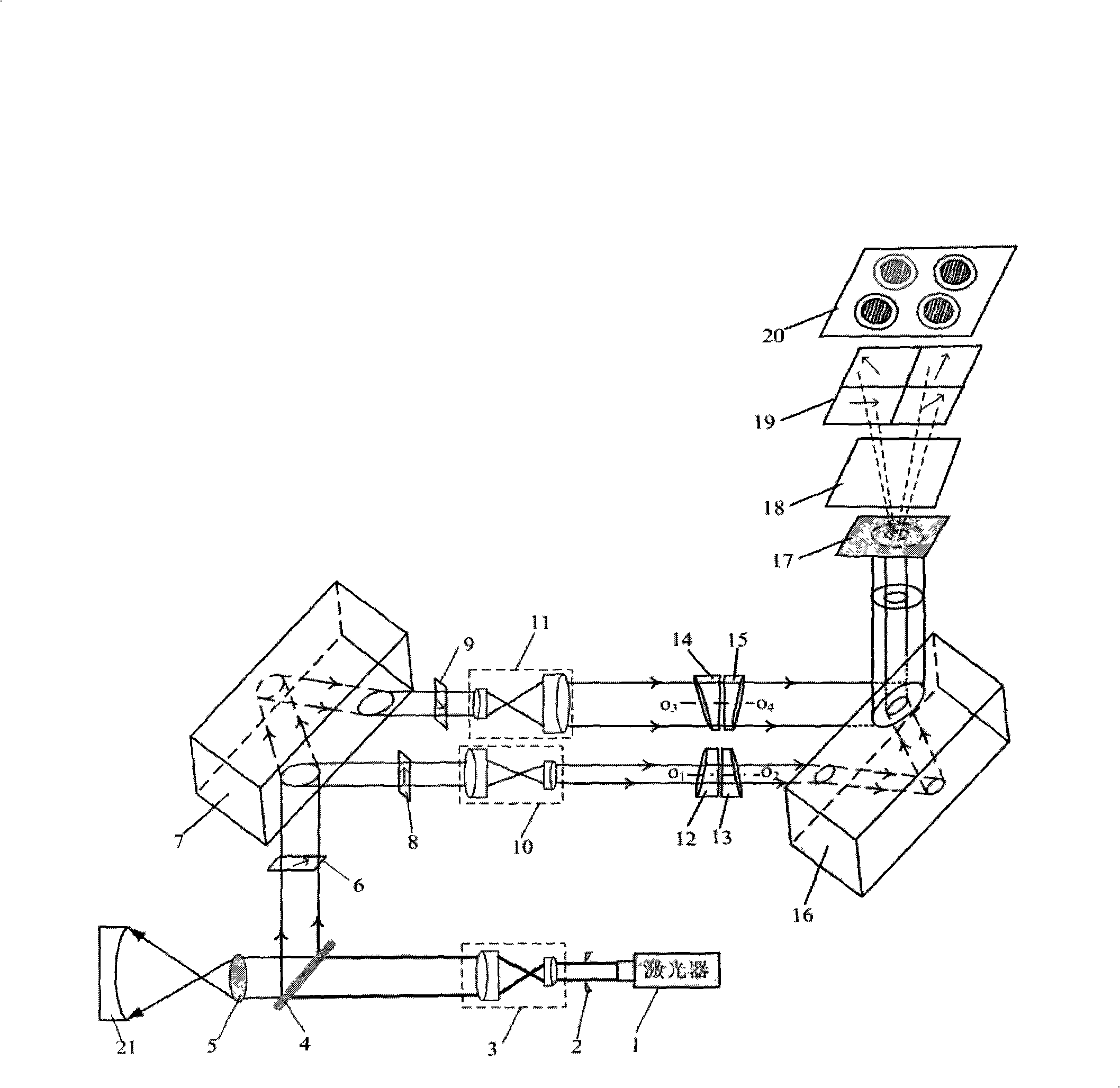

[0043] Such as figure 1 As shown, the combined interference device for measuring aspheric surface shape of the present invention has a laser 1, and a spatial filter 2, a beam expander system 3, a beam splitter 4, a conversion lens 5, The measured aspheric mirror 21; the laser light reaches the measured aspheric surface 21 and is reflected back by the measured aspheric surface 21, and is incident on the beam splitter 4 through the conversion lens 5 again and is reflected by the beam splitter 4, after being reflected by the beam splitter 4 The first vertical optical path is formed, and the 45° polarizer 6 and the first optical flat plate 7 are successively placed on the vertical optical path. After the laser passes through the first optical flat plate 7, two horizontal optical paths are formed. The vertical polarizer 8, the beam shrinker system 10, the first optical wedge 12, and the second optical wedge 13 are arranged in order; the horizontal polarizer 9, the beam expander sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com