Production method of LED

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of light output intensity limitation of light-emitting diodes, reduction of light output intensity of light-emitting diodes, and inability to be effectively used, so as to improve quality and The effect of brightness presentation, improvement of light extraction efficiency, and enhancement of light output intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

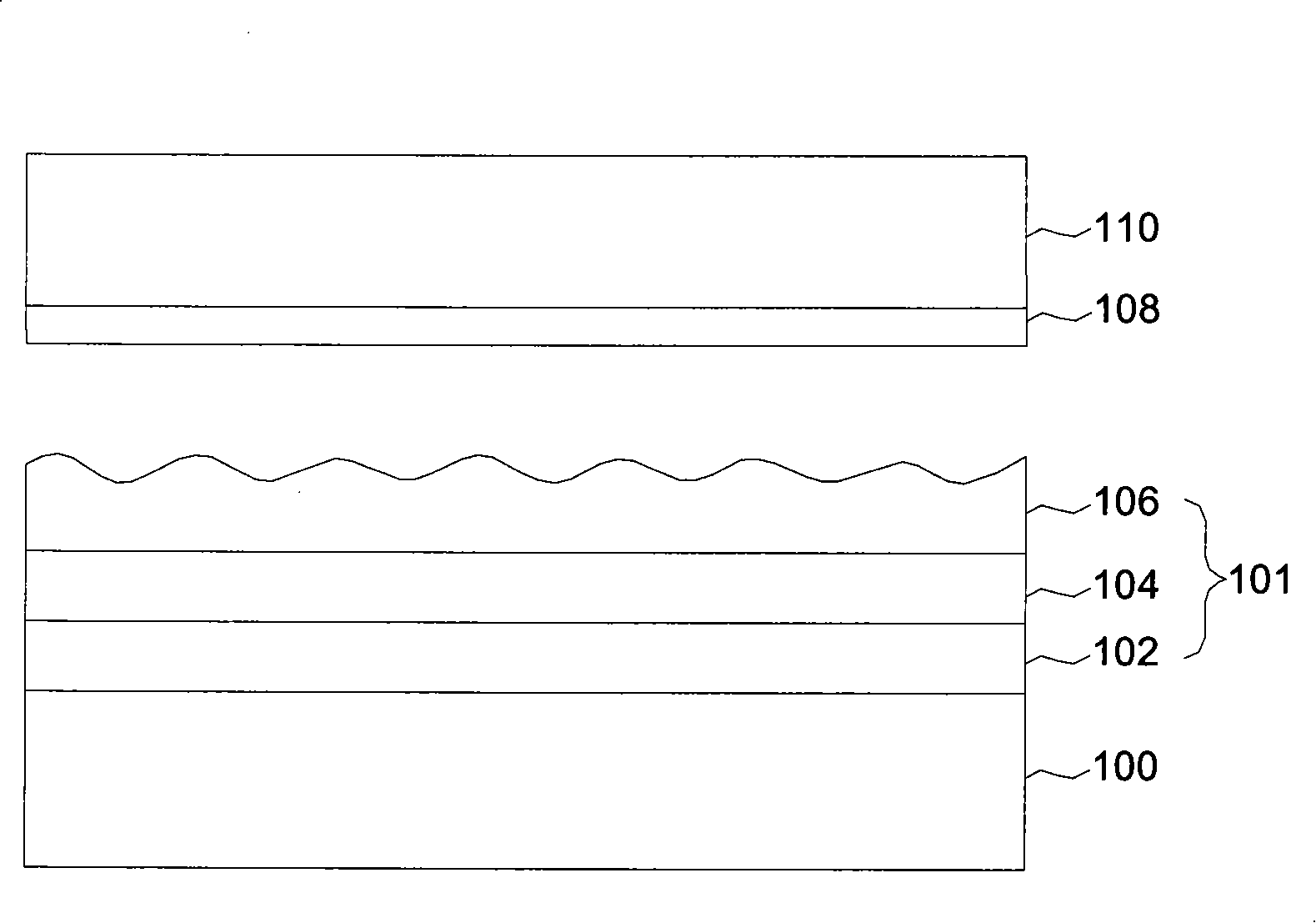

[0027] A flip-chip light emitting diode disclosed in the present invention, Figure 1A to Figure 1D It is a schematic cross-sectional view of a process flow of a flip-chip manufacturing method of a light emitting diode according to an embodiment of the present invention.

[0028] in Figure 1A In the first step, a light-emitting diode epitaxial structure 101 is fabricated on a substrate 100. The light-emitting diode epitaxial structure 101 described here includes aluminum gallium indium phosphide light-emitting diodes (AlGaInP) and aluminum gallium indium nitride light-emitting diodes (AlGaInN). In order to obtain an epitaxial structure with good crystal quality, when manufacturing aluminum gallium indium phosphide (AlGaInP) light-emitting diodes, the substrate 100 is selected from germanium (Ge), gallium arsenide (GaAs) or indium phosphorus (InP), and When manufacturing aluminum gallium indium nitride (AlGaInN) light-emitting diodes, the substrate 100 is selected from sapphire (S...

Embodiment 2

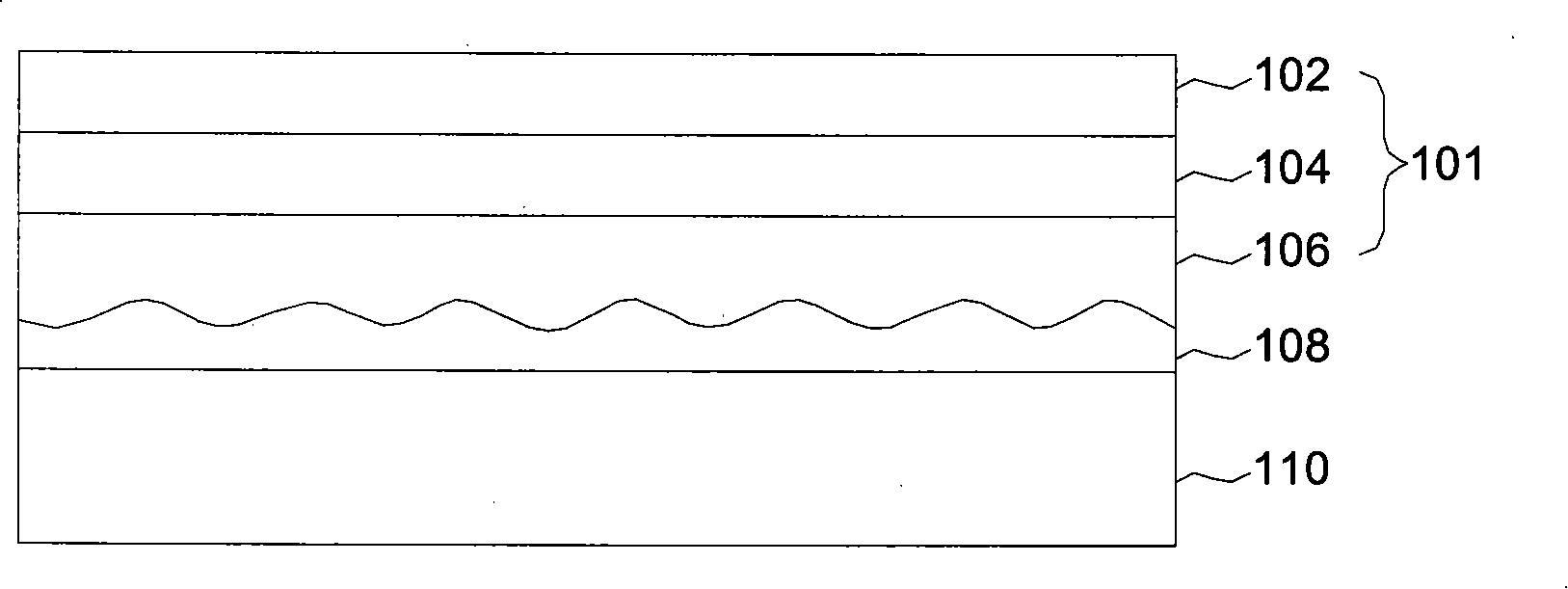

[0038] Reference figure 2 Shown is a schematic diagram of another flip-chip light emitting diode 20 according to a preferred embodiment of the present invention. In this embodiment, in addition to the steps described in embodiment 1, the upper surface of the transparent substrate 210 can be further roughened to form uneven surface characteristics, so that the light-emitting diodes can emit light outward. The increase further contributes to improving the light extraction efficiency of the light emitting diode and the light output intensity of the entire light emitting diode.

[0039] Furthermore, at the interface between the transparent substrate 210 and the soft transparent adhesive layer 208, and the lower surface of the transparent substrate 210, an uneven joint surface is formed, so that it has a rough surface characteristic of unevenness.

[0040] The roughening treatment of the upper and lower surfaces of the transparent substrate 210, for example, can be formed before the tr...

Embodiment 3

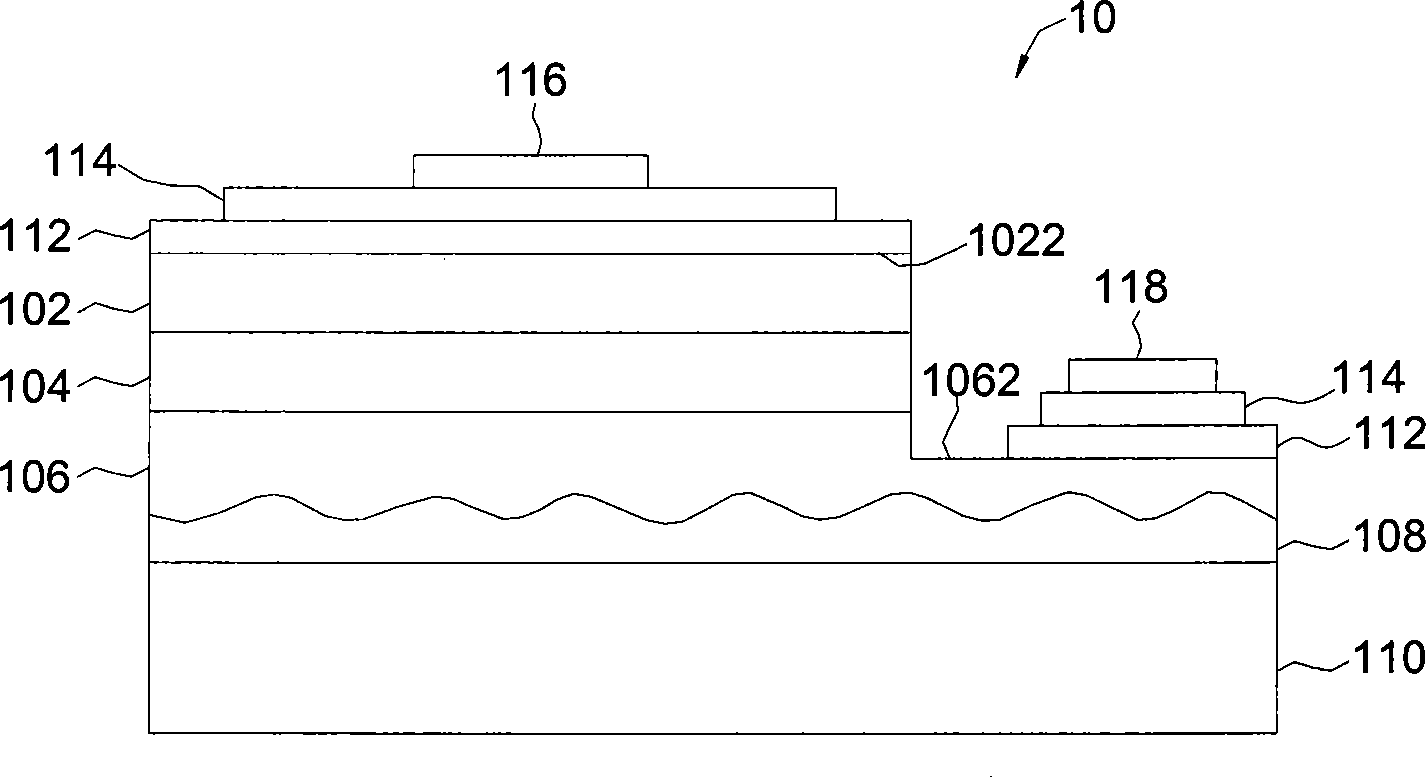

[0042] The present invention further discloses a flip-chip light emitting diode, such as Figure 3D As shown, Figure 3A-3D It is a schematic cross-sectional view of the flow of the flip-chip manufacturing method of the light emitting diode according to the preferred embodiment of the present invention.

[0043] According to the steps described in embodiment 1, an n-type semiconductor layer 302, a light-emitting active layer 304, and a p-type semiconductor layer 306 are respectively formed on the substrate 300 to fabricate a light-emitting diode epitaxial structure 301, such as Figure 3A Shown. Similarly, the light-emitting active layer 304 may have a homogenous structure, a single heterostructure, a double heterostructure, or a multiple quantum well structure.

[0044] Then, a temporary substrate 310 coated with a soft transparent adhesive layer 308 on the surface is attached to the light emitting diode epitaxial structure 301, and the temporary substrate 310 is attached using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com