Olig-(polyethylene glycol) bonding silica-gel stationary phase and method for preparing the same

A technology of oligoethylene glycol and bonded silica gel, applied in the field of chromatographic stationary phase, can solve problems such as the influence of separation performance, and achieve the effects of good separation selectivity, simple and reliable preparation process, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

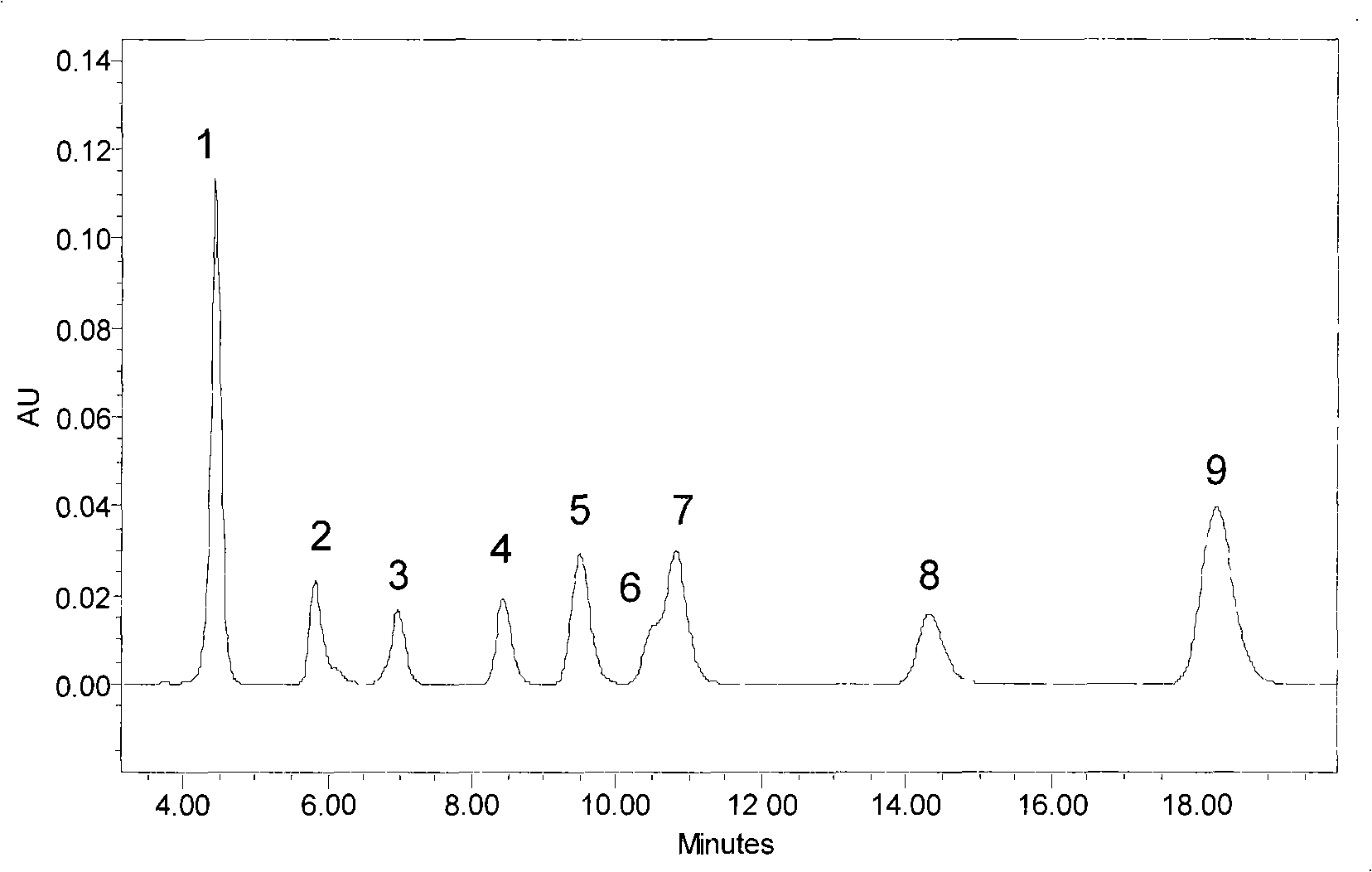

Examples

Embodiment 1

[0038]In a 1000ml three-necked flask, add 500ml of anhydrous DMF, 45mmol (about 10ml) of 3-chloropropyltriethoxysilane, 60mmol (about 4.0g) of sodium azide, and then add 3.0mmol of sodium iodide (about 0.5g) As a catalyst, react at 80°C for 24h, then add 20g of spherical silica gel particles with a particle size of 5μm, react at 80°C for another 24h, and then wash with dichloromethane, ethanol, water, and acetone twice, each time 200ml, 60 °C and vacuum-dried for 12 hours to obtain (3-propyl)azido silica gel.

[0039] Add 100ml of dry THF and 10g of tetrapolyethylene glycol into a 250ml three-necked flask, cool to -5°C, add 1.5g of sodium hydride under stirring conditions, react for 15 minutes at -5~0°C, and then add 5.6ml with a volume concentration of 80% propargyl bromide in toluene solution, react at -5~0°C for 2 hours, rise to room temperature and continue to react for 2 hours. The reaction system was subjected to simple post-treatments such as filtration and concentrati...

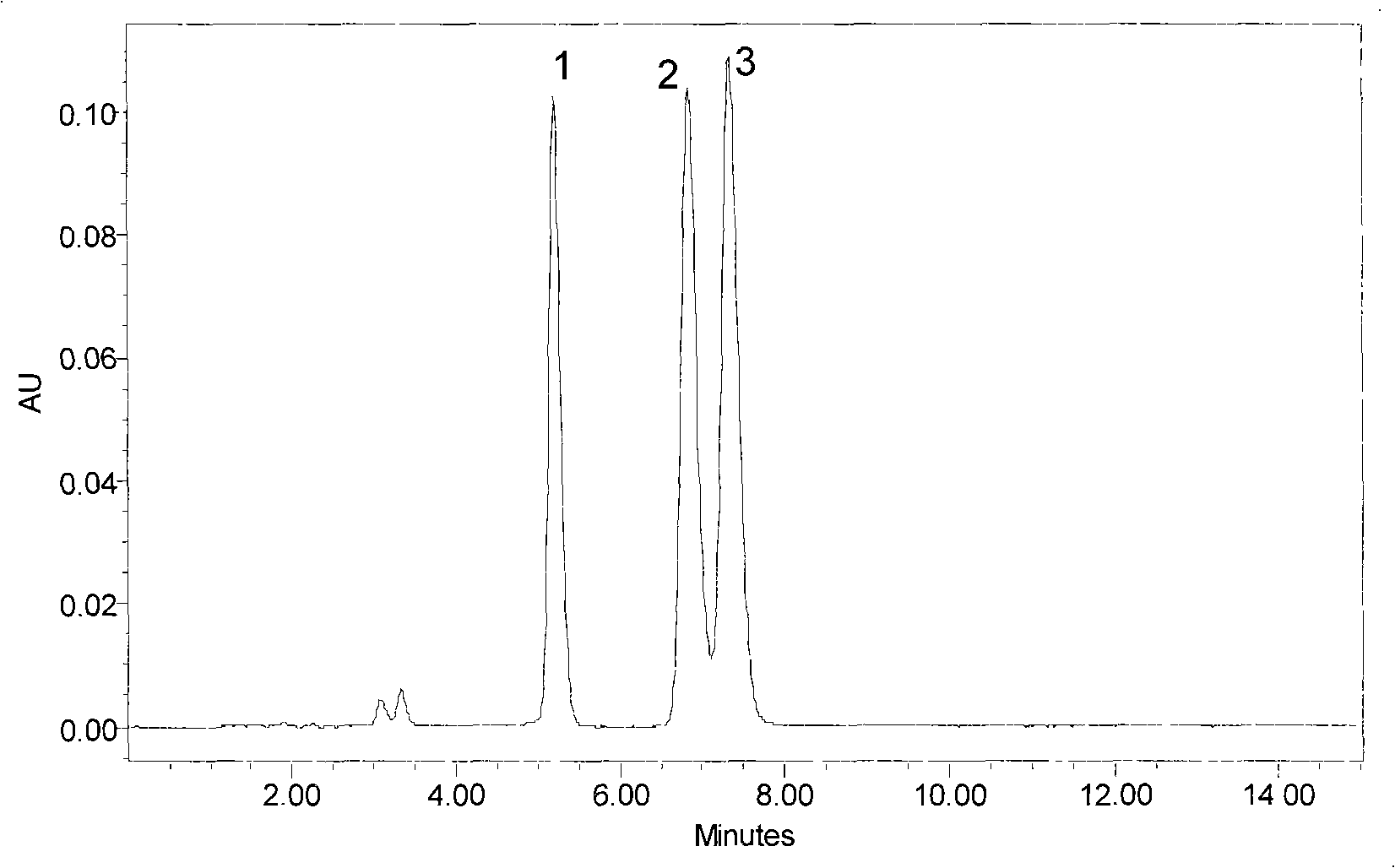

Embodiment 2

[0043] The difference from Example 1 is that tripolyethylene glycol is used instead of tetrapolyethylene glycol, and another kind of oligoethylene glycol stationary phase (OEG-3) can be obtained according to the synthesis steps of Example 1, the structure of which is The structure is:

[0044]

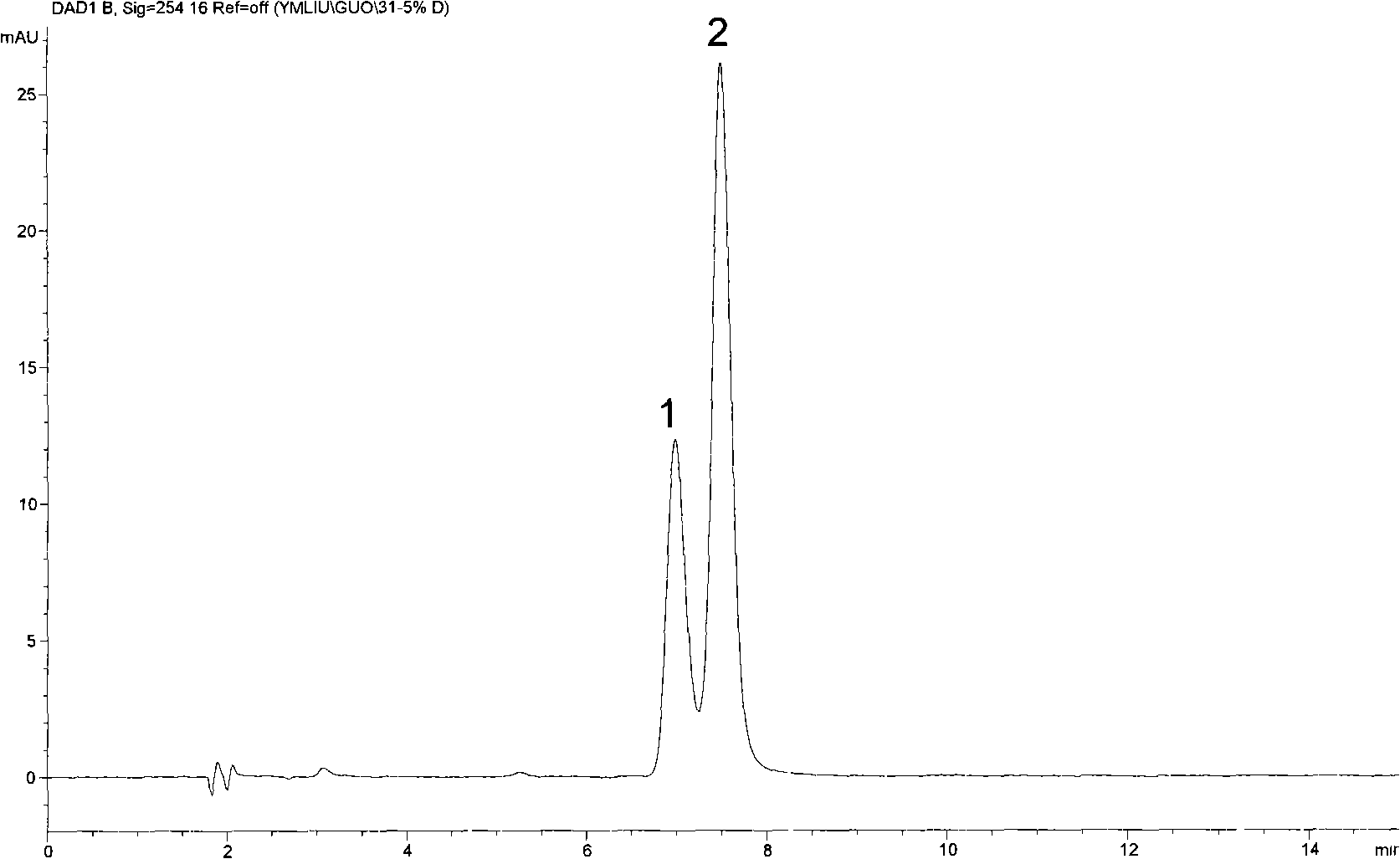

Embodiment 3

[0046] The difference from Example 1 is that polyethylene glycol with an average molecular weight of 400 is used instead of tetrapolyethylene glycol, and another kind of oligoethylene glycol stationary phase (OEG400) can be obtained according to the synthesis steps of Example 1, and the structure is Its structure is:

[0047]

[0048] Wherein n=8~9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com