Moulding method of magnesium alloy ultrathin sheet material

A sheet metal forming, magnesium alloy technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of many product defects, residual stress of sheet metal, poor plastic processing performance, etc., and achieve corrosion resistance and electrochemistry, etc. Improved performance, weakened basal texture, and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

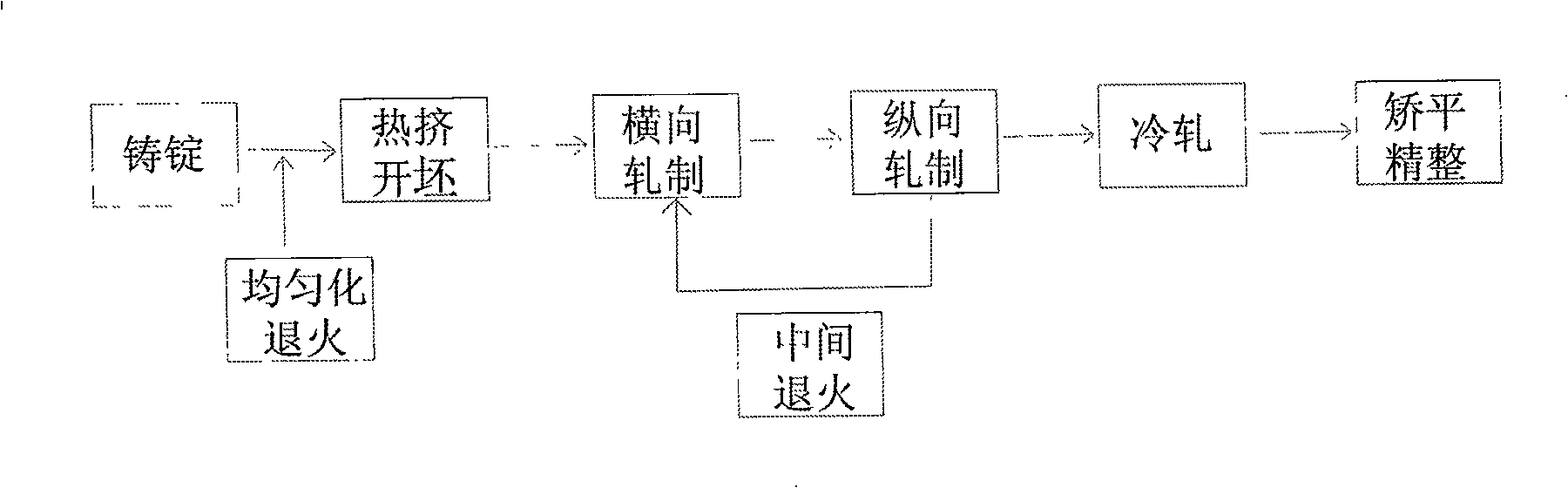

[0022] The magnesium power battery anode plate produced by the forming process of the present invention is formed by uniform annealing, extrusion blanking, multi-pass transverse-longitudinal rolling, cold rolling, leveling and finishing, and the thickness of the anode magnesium alloy plate can be determined according to the battery Model selection, the minimum thickness can reach 0.1mm, and the thickness tolerance is ±0.01.

[0023] The ultra-thin magnesium alloy anode plate is completed through the following implementation steps on the basis of smelting the cast ingot.

[0024] (1) Ingot Homogenization Treatment

[0025] The ingot is kept at 648-688K for 22-25 hours under the protection of inert gas, and the ingot is homogenized.

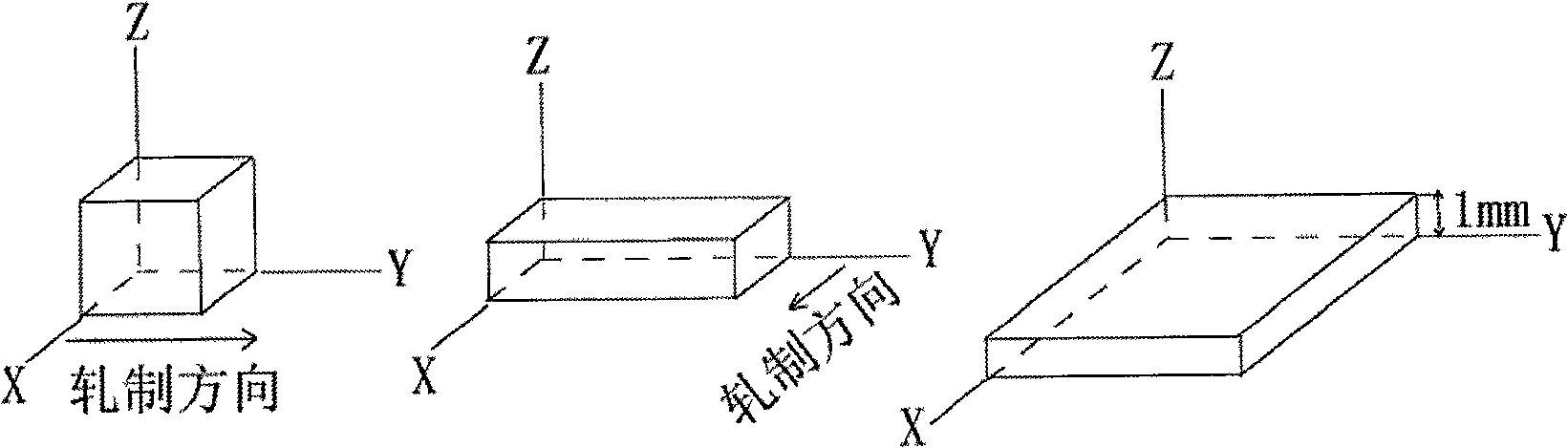

[0026] (2) Ingot hot extrusion billet

[0027] The homogenized ingot is directly extruded by hot extrusion. The total deformation of the hot extrusion billet reaches more than 40%, and the pass reduction is about 15%, so that the as-cast structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com