Film separated activated sludge apparatus

An activated sludge and membrane separation technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problem of low BOD volume load, reduce sludge production rate, Unable to achieve high flux and other problems, to achieve the effect of preventing water quality deterioration and delaying clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

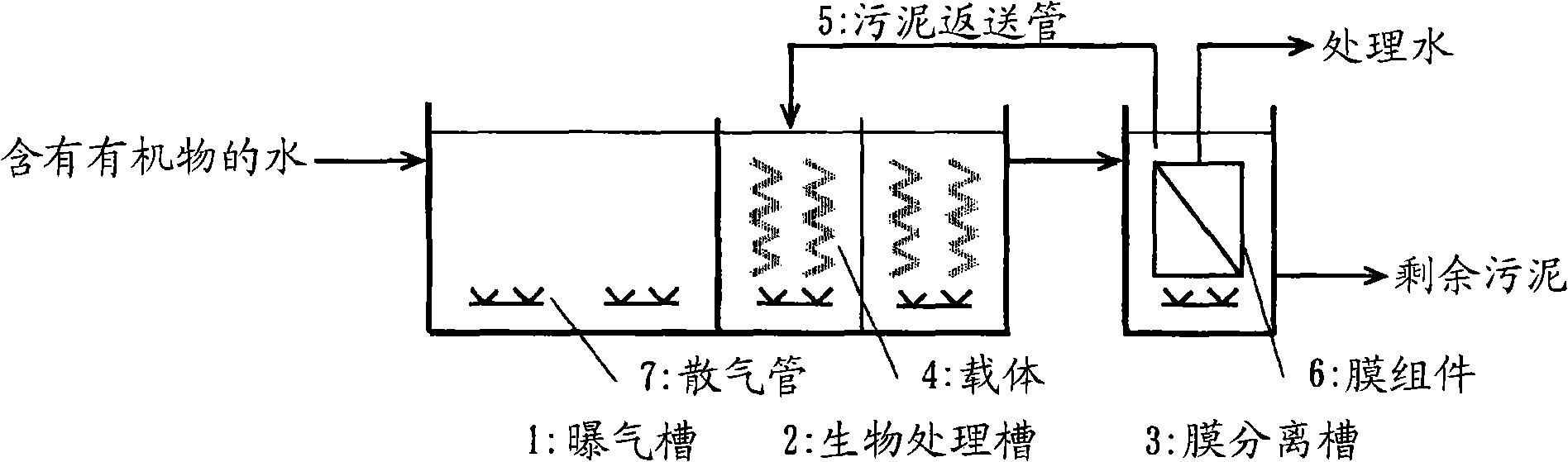

[0099] The membrane separation activated sludge device used in this embodiment is shown in figure 1 . The aeration tank 1 (capacity 12L), the biological treatment tank 2 (capacity 12L), and the membrane separation tank 3 (capacity 4L) were connected in series in the direction from upstream to downstream of the flow of water containing organic matter. Aeration pipes 7 are respectively provided in each tank to allow aeration. The biological treatment tank 2 is equally divided into two stages, and fixed-bed carriers are arranged in the two stages. The fixed bed type carrier adopts a spiral shape with a length of 60 cm and an outer diameter of 8 cm made by making a polyvinylidene chloride fiber into a ring shape with a length of 1.5 cm, and fixing a part of it on a copper core material wrapped in plastic. carrier.

[0100] A membrane module (hollow fiber membrane made of PVDF, 0.1 μm in pore size, 0.035 m in membrane surface area) is installed in the membrane separation tank 3 ...

Embodiment 2

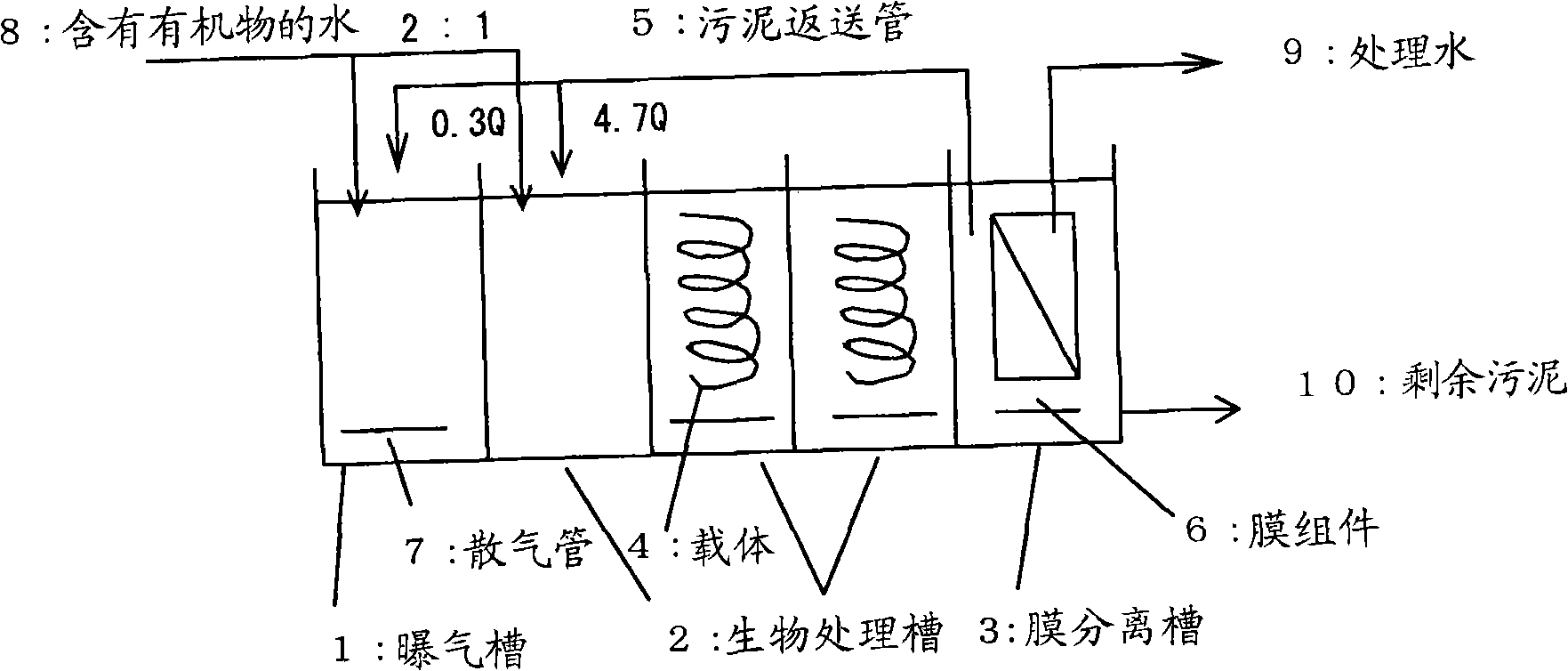

[0104] The membrane separation activated sludge device used in this embodiment is shown in figure 2 . Aeration tank 1 (capacity 2m 3 ), biological treatment tank 2 (capacity 6m 3 = 2m 3 ×3 tanks) and membrane separation tank 3 (capacity 2m 3 ) are connected in series along the upstream to downstream direction of the flow of water containing organic matter. Biological treatment tank 2 is divided into 3 levels. In the upper stage, the flow is carried out by propeller agitation without aeration. The middle stage and the lower stage are respectively provided with diffuser pipes 7 for aeration, and respectively provided with fixed-bed carriers 4 . The fixed bed carrier 4 adopts a helix with a length of 1.8 m and an outer diameter of 8 cm made by making a polyvinylidene chloride fiber into a ring shape with a length of 1.5 cm, and fixing a part of it on a copper core material wrapped in plastic. shape carrier. Two sets of membrane modules (hollow fiber membranes made of PVD...

Embodiment 3

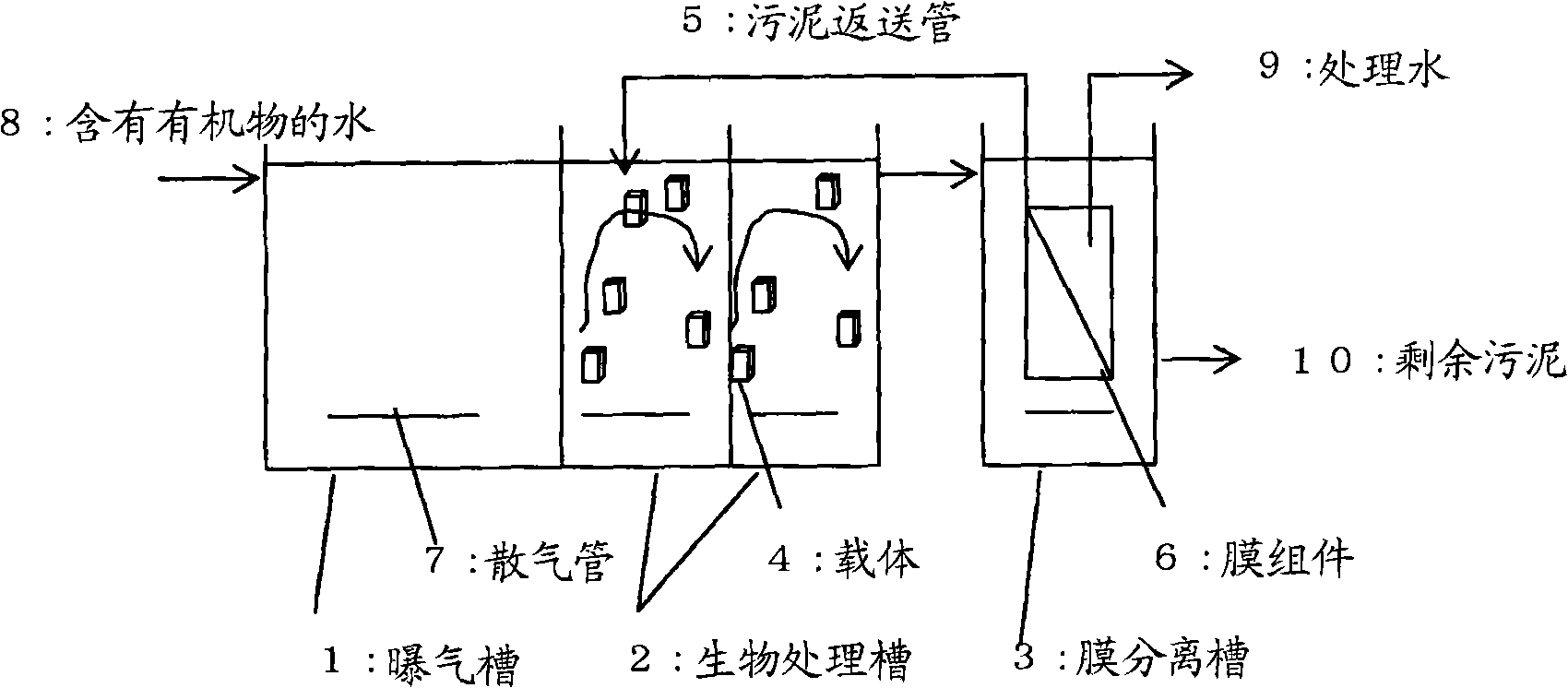

[0108] Using the same device as in Example 1, the carrier 4 in the biological treatment tank 2 was replaced with a flow carrier. A summary of the device is shown in Figure 4 . As the mobile carrier 4, a soft polyurethane sponge 7 mm square carrier "Bio-colony" (BIO-colony) for water treatment microorganisms manufactured by Achilles Co., Ltd. was used. After acclimatization, the volumetric load of BOD is kept constant at 1.5kg / m per day after inputting a fluid carrier with a volume ratio of 20% to the biological treatment tank 2 3 , keep the flux constant at 0.7m per day 3 / m 2 , The membrane module was continuously operated without backwashing or membrane cleaning, and the differential pressure between the membranes (TMP) was measured.

[0109] After 45 days, TMP increased by 7kPa, and the membrane fouling rate (daily TMP increase) was 0.66kPa per day, which was low enough for practical use. The sludge production rate was calculated from the amount of excess sludge disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com