Noble metal/phenolic resin biocompatible material having core-shell structure and preparation thereof

A technology of biocompatibility and core-shell structure, applied in the field of preparation of precious metal/phenolic resin core-shell structure, can solve the problems of no biological fluorescent material research, single magnetic properties, weakening of fluorescence properties, etc. Large-scale production, time-durable fluorescent properties, effects of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

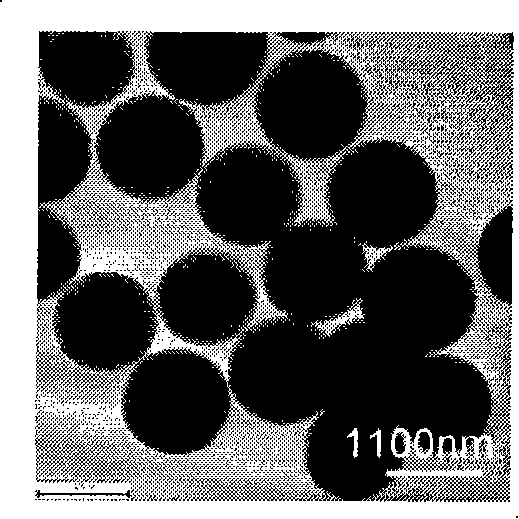

[0028] First mix 10ml 0.1mol / L phenol and 5ml 0.5mol / L hexamethylenetetramine aqueous solution, then add 1ml 10 -3 -10 -5 mol / L silver nitrate solution, add water to a total volume of 22ml, seal the above solution in a reaction vessel, react at 180°C for 4 hours, wash the product three times with water and ethanol to remove impurities respectively, and obtain silver / phenolic resin partial Particles with a core structure, the particle size is 1000nm.

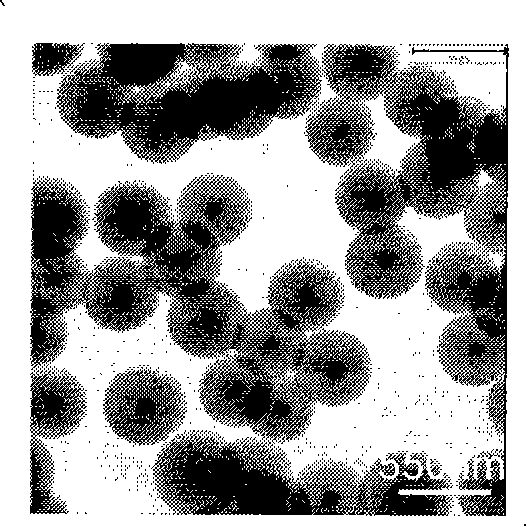

[0029] Weigh 0.02g silver / phenolic resin partial core-shell particles and place them in 10ml benzyl alcohol, ultrasonically disperse them evenly, then add 0.2mmol Fe(acac) 3 , heated to 200°C for 3 minutes, and kept at a constant temperature for 5 minutes to obtain Fe 3 o 4 Coated Silver / Phenolic / Fe 3 o 4 particles with a three-layer core-shell structure.

[0030] Weigh 0.02g of silver / phenolic resin particles with partial core-shell structure and place them in 20ml of water, ultrasonically disperse them evenly, then add 0....

Embodiment 2

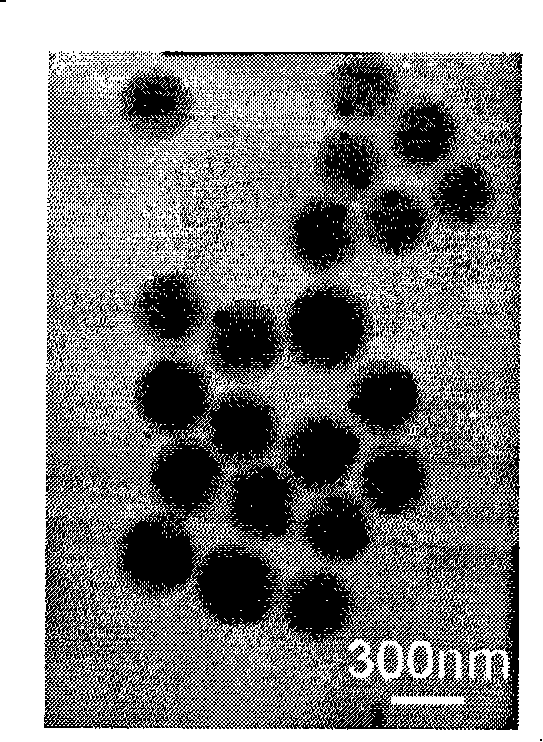

[0039] First mix 5ml 0.1mol / L phenol and 10ml 0.5mol / L hexamethylenetetramine aqueous solution, then add 0.1ml 10 -3 -10 -5 mol / L silver nitrate solution, add water to a total volume of 22ml, seal the above solution in a reaction vessel, react at 180°C for 4 hours, wash the product three times with water and ethanol to remove impurities respectively, and obtain silver / phenolic resin partial Nanoparticles with a core structure, the particle size is 500nm.

[0040] Weigh 0.01g silver / phenolic resin partial nucleus structure nanoparticles and put them in 10ml benzyl alcohol, ultrasonically disperse them evenly, then add 0.2mmol Fe(acac) 3 , heated to 200°C for 3 minutes, and kept at a constant temperature for 5 minutes to obtain Fe 3 o 4 Coated Silver / Phenolic / Fe 3 o 4 particles with a three-layer core-shell structure.

[0041] Weigh 0.02g silver / phenolic resin partial nucleus structure nanoparticles and put them in 20ml water, ultrasonically disperse them evenly, then add ...

Embodiment 3

[0051] First mix 5ml 0.1mol / L phenol and 5ml 0.5mol / L hexamethylenetetramine aqueous solution, then add 0.1ml 10 -3 -10 -5 mol / L silver nitrate solution, add water to a total volume of 22ml, seal the above solution in a reaction vessel, react at 180°C for 4 hours, wash the product three times with water and ethanol to remove impurities respectively, and obtain silver / phenolic resin positive Nanoparticles with a core structure, the particle size is 500nm.

[0052] Weigh 0.02g silver / phenolic resin positive core-shell nanoparticles and place them in 20ml distilled water, ultrasonically disperse them evenly, then add 0.2mmol FeSO 4 , 0.1mmol of hexamethylenetetramine, heated to 200°C for 5 minutes, and kept at constant temperature for 5 minutes to obtain Fe 3 o 4 Coated Silver / Phenolic / Fe 3 o 4 three-layer core-shell structure particles.

[0053] Weigh 0.02g silver / phenolic resin positive core-shell nanoparticles and place them in 20ml water, ultrasonically disperse them ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com