Anaerobic fermentation method and device of alcohol waste Liquid

A technology of anaerobic fermentation and anaerobic fermentation tank, which is applied in the field of enzyme treatment of waste liquid, can solve problems such as difficulties, and achieve the effects of saving energy, good mass transfer effect, and improving speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

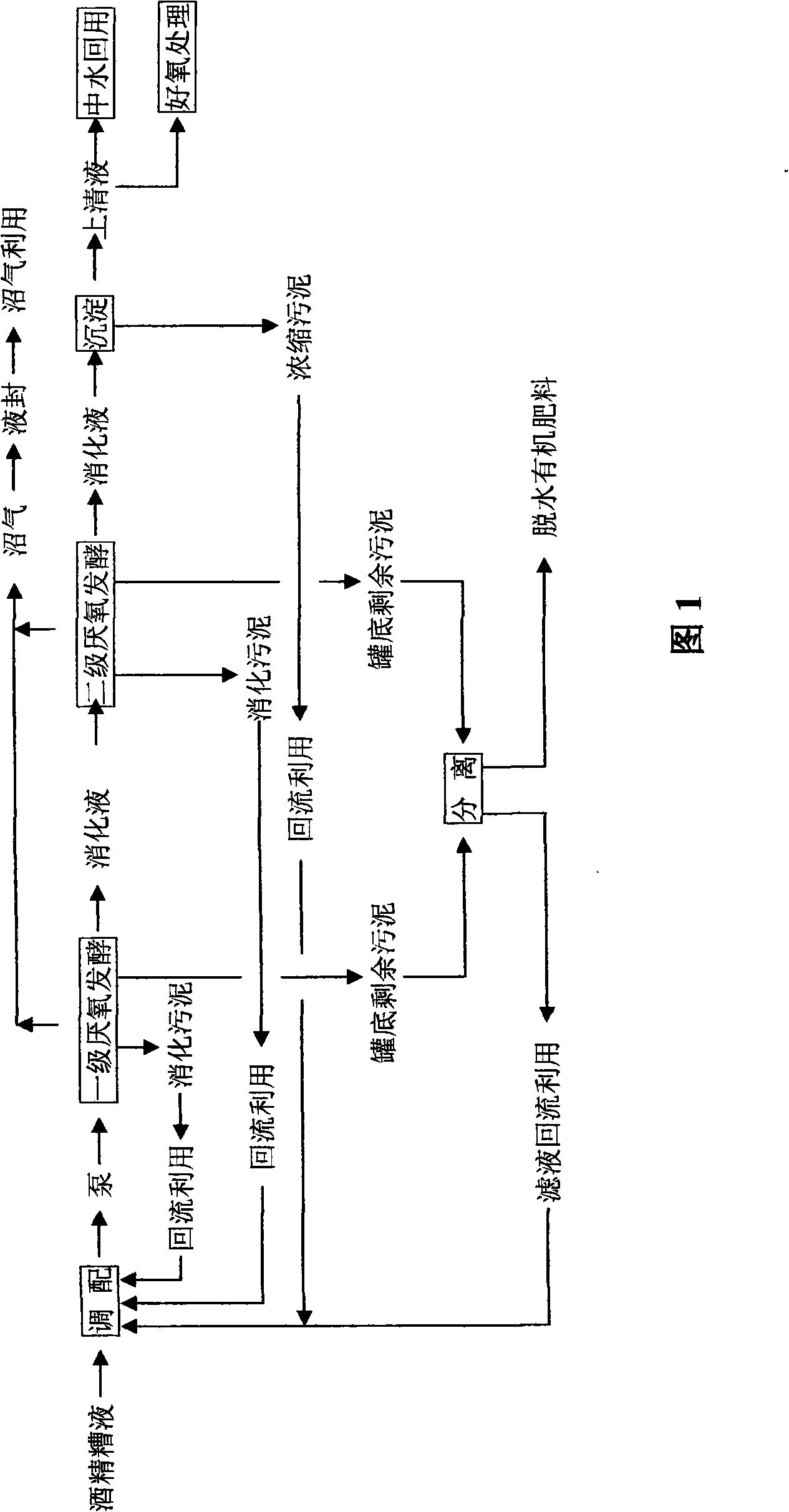

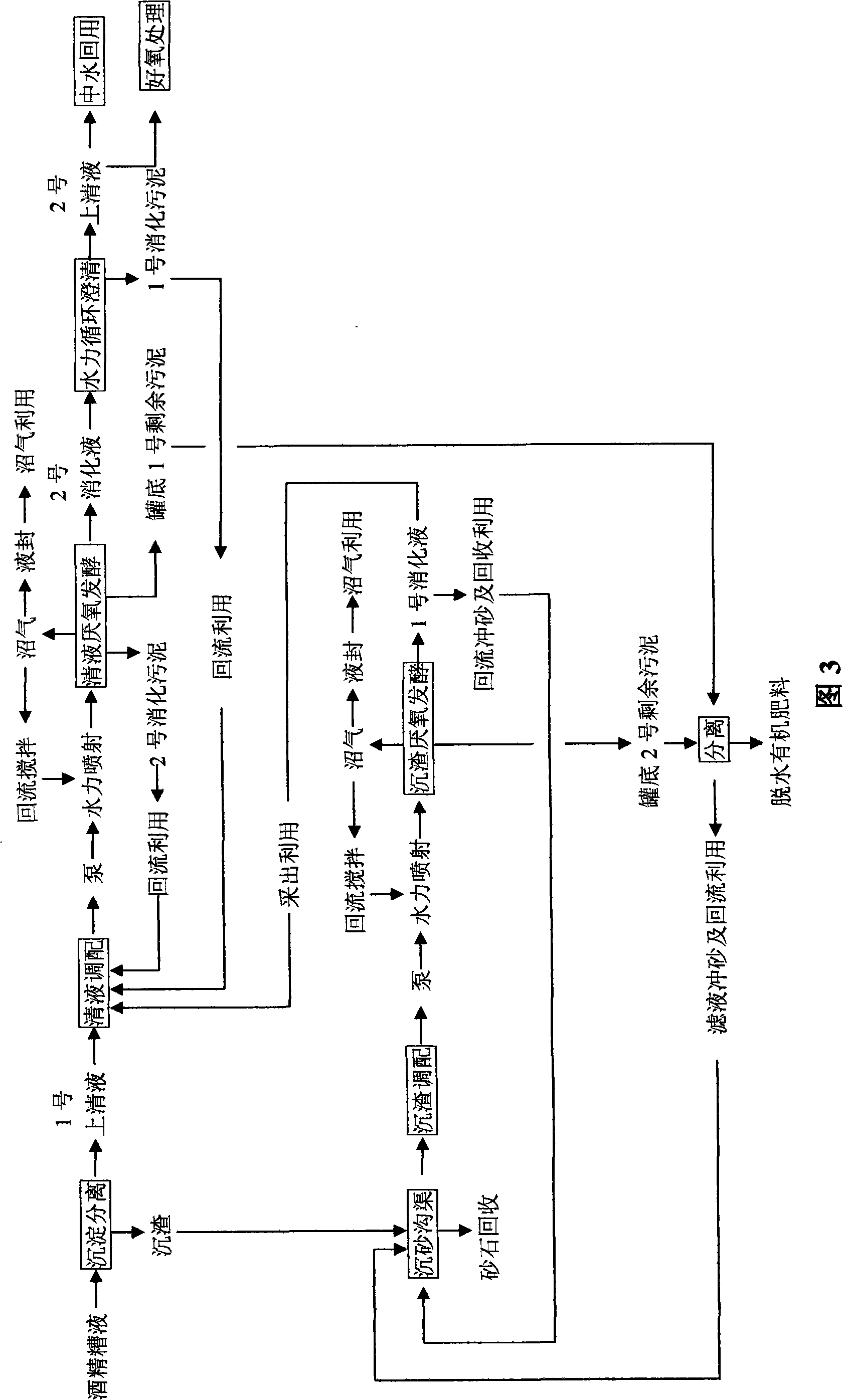

[0028] According to the technological process shown in Figure 3 and the equipment process shown in Figure 4, a production line device for anaerobic fermentation of distiller's grains with an annual output of 10,000 tons of alcohol is installed. In this device, distiller's grains are separated into sediment and No. 1 supernatant through the distiller's grains settling tank 2. Anaerobic fermentation tank 13 inside. This feeding method is called the "double flow addition" method. When the extracted digestive juice enters the clear liquid anaerobic fermentation tank 13, a series connection between two tanks is adopted. The material entering the fermenter is not only stirred by the eddy current of the water distributor, but also the biogas sucked by the jet pump strengthens the stirring. In the two anaerobic fermentation tanks, the total hydraulic retention period is 16 days, which makes the anaerobic fermentation technology tend to be "big anaerobic". In the sediment anaerobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com