Sandwich heat preserving wall body and building method thereof

A technology of thermal insulation wall and construction method, applied in thermal insulation, building structure, wall and other directions, can solve the problems of material waste, non-compliance with energy saving, emission reduction and environmental protection, and energy consumption of thermal insulation materials and consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

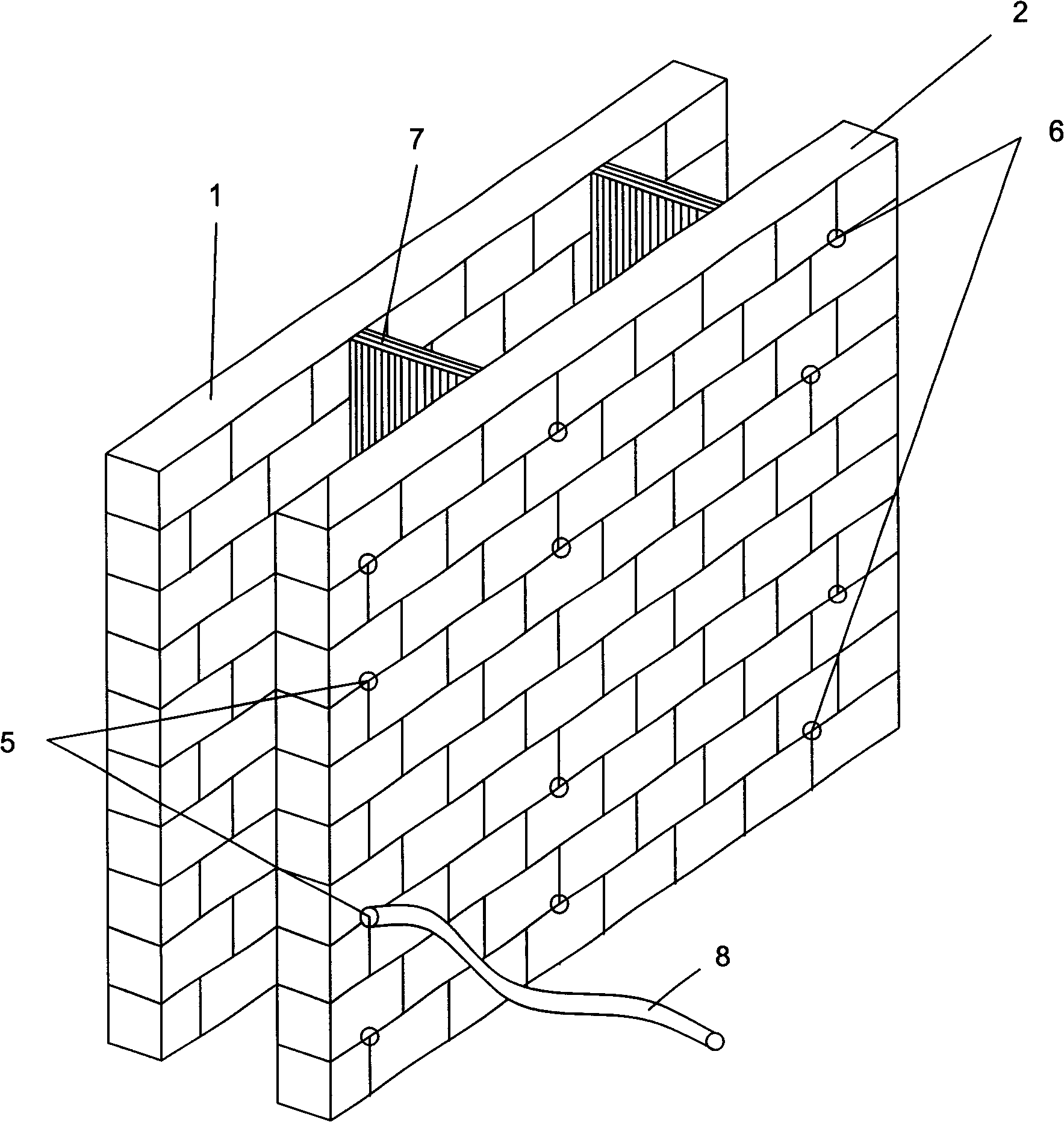

[0018] There is a drill hole (3) at the mortar joint of any leaf wall of the inner and outer leaf walls (1) or (2), through which the hole is injected into the cavity between the inner and outer leaf walls Insulation foam material.

[0019] The thermal insulation foaming material is urea-formaldehyde foaming material or polystyrene foaming material or nitrogen urea foaming material or polyurethane foaming material.

[0020] At least one leaf wall of the two inner and outer leaf walls is made of non-load-bearing hollow blocks.

[0021] The load-bearing blocks are solid bricks or hollow bricks.

[0022] Boreholes (3) are inspection holes (6) and / or pouring holes (5).

[0023] The positions of the pouring holes (5) are at 1 / 4 and 3 / 4 of the height of each floor wall, and the thermal insulation material is poured into the cavity between the inner and outer leaf walls on-site by spray guns.

[0024] Inspection holes (6) are located at 1 / 2 of the wall height and / or at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com