Color coating wire harmful gas central incineration residual heat utilization

A harmful gas and color coating line technology, which is applied to the surface coating liquid device, coating, incinerator, etc., can solve the problems of polluting the environment, energy consumption, etc., and achieve the goal of reducing heat emission, saving costs, and solving environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

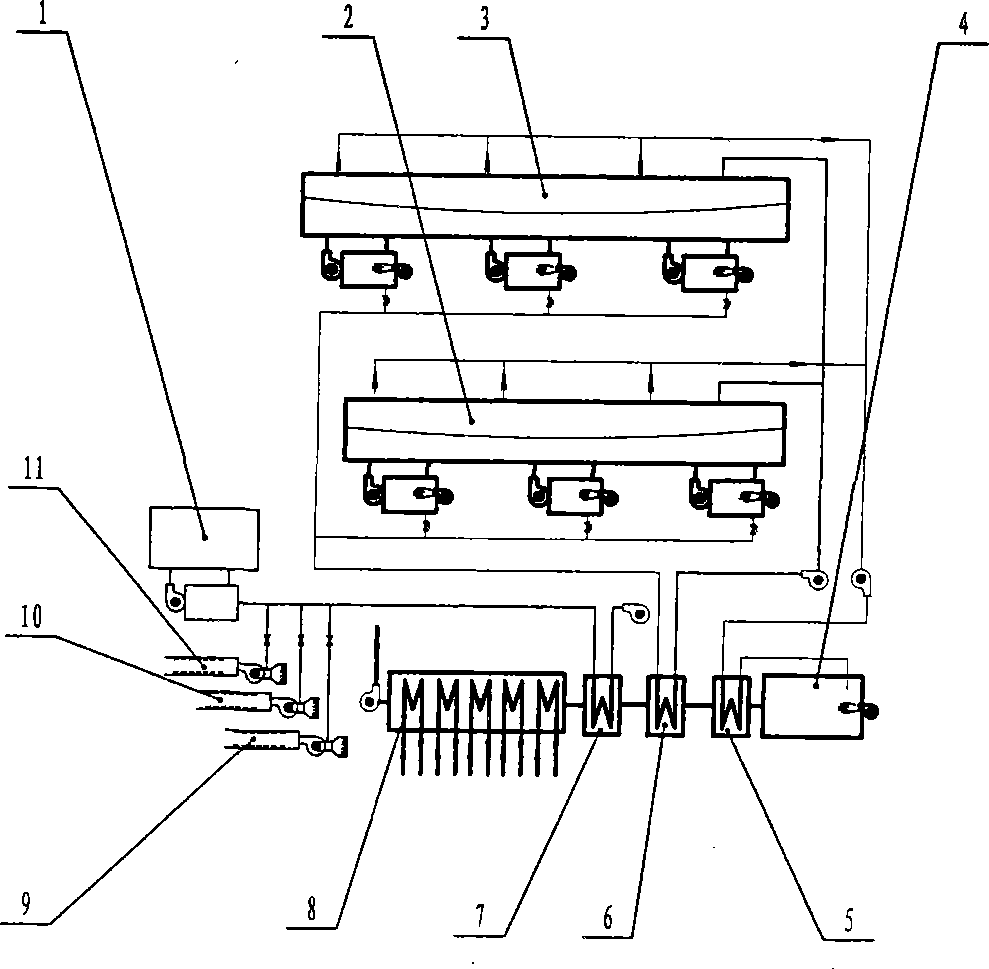

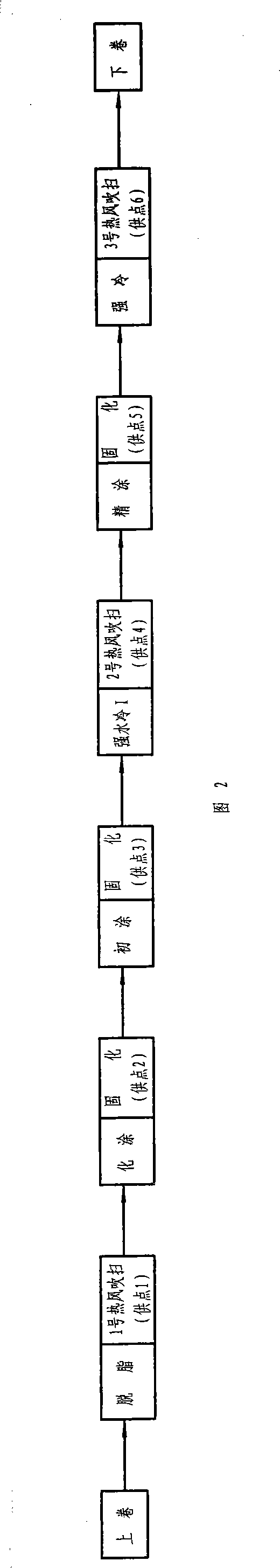

[0010] Concentrated incineration waste heat utilization of harmful gases in the color coating line is composed of exhaust gas incinerator 4 and exhaust gas preheater 5, etc. The exhaust gas at about 250 ° C from the primary coating furnace 2 and finishing coating furnace 3 is drawn by the induced draft fan through the exhaust gas preheater 5 After preheating to about 350-400°C, send it to the exhaust gas incinerator 4. After heating to the cracking and incineration temperature above 733°C, a large amount of heat energy greater than 650-700°C will be generated, and the fresh air will come from the first stage of the exhaust gas of the curing furnace containing very little exhaust gas. Heater 6 replaces the hot air at 420-450°C to supply the primary coating furnace 2 and the finishing coating furnace 3 for heating. The control of the furnace temperature is realized by PID. A spare burner is installed on the heating head of the furnace 3 to adjust the temperature, and the heat sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com