Capacitance temperature type ice covering thickness sensor

A technology of ice coating thickness and sensors, applied in the direction of electric/magnetic thickness measurement, thermometers, thermometers using electric/magnetic elements that are directly sensitive to heat, etc., can solve the problem of low automation and the inability to grasp the change of ice layer structure process, the prediction and prediction of ice-covered generation and disappearance on the surface of objects, etc., to achieve the effect of strong anti-interference ability and simple judgment and calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

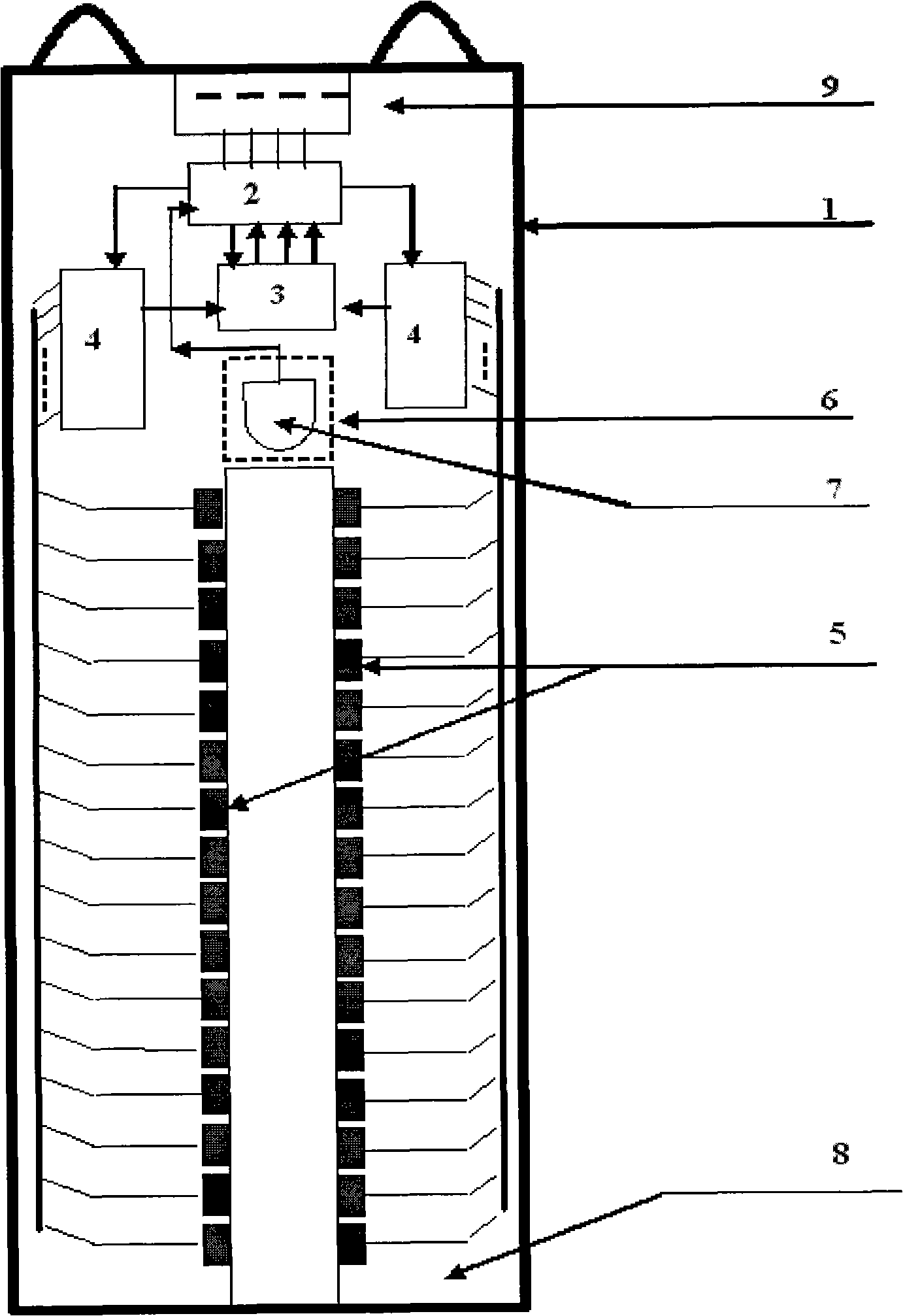

[0026] Implementation mode 1: Detection of the thickness of suspended ice coating on high-voltage transmission lines:

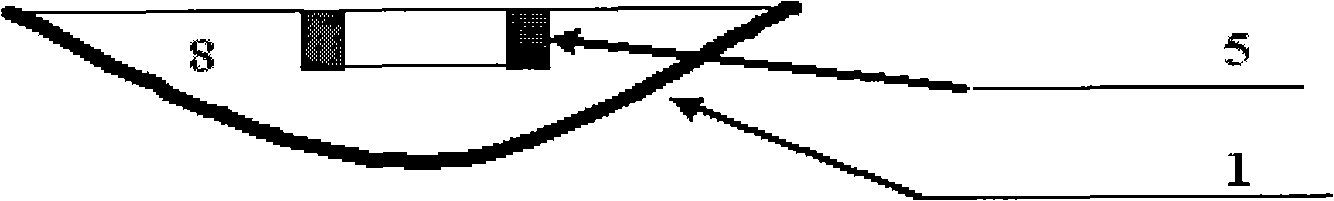

[0027]First, hang the sensor shown in the drawing vertically and fix it on any part of the transmission line, and connect the sensor wire connection socket 9 with the working power supply and signal transmitting device fixed on the transmission line tower through a shielded multi-core waterproof cable. When detecting, the single-chip microcomputer 2 inside the sensor sends a decoding gate control signal to the two-way programmable control scale gate circuit 4 according to a certain coding sequence through its own I / O interface according to the pre-programmed program, so that the two-way programmable The control scale gating circuit 4 connects the common output terminals to each input terminal in turn according to the coding sequence, so that the plates on both sides of the capacitance of each parallel plate detection capacitor 5 are respectively connected to t...

Embodiment approach 2

[0028] Implementation mode 2: Detection of the suspended ice thickness of the high-voltage line tower:

[0029] First, hang the sensor shown in the drawing vertically and fix it on any part of the high-voltage line tower, connect the sensor wire connection socket 9 with the working power supply and signal transmitting device fixed on the high-voltage line tower through a shielded multi-core waterproof cable, and detect Firstly, the single-chip microcomputer 2 inside the sensor sends a decoding strobe control signal to the two-way programmable control scale strobe circuit 4 through its own I / O interface according to a certain coding sequence according to the pre-programmed program, so that the two-way programmable control The scale gating circuit 4 connects the common output terminals to each input terminal in turn according to the coding sequence, so that the plates on both sides of the capacitance of each parallel plate detection capacitor 5 are respectively connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com