Inorganic mixed type lithium ion super capacitor

A supercapacitor and hybrid technology, applied in the field of capacitors, can solve problems such as cycle life needs to be further improved, cycle life is not ideal, and manufacturing process is complicated, etc., to achieve the effect of increasing energy density, improving utilization rate, and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

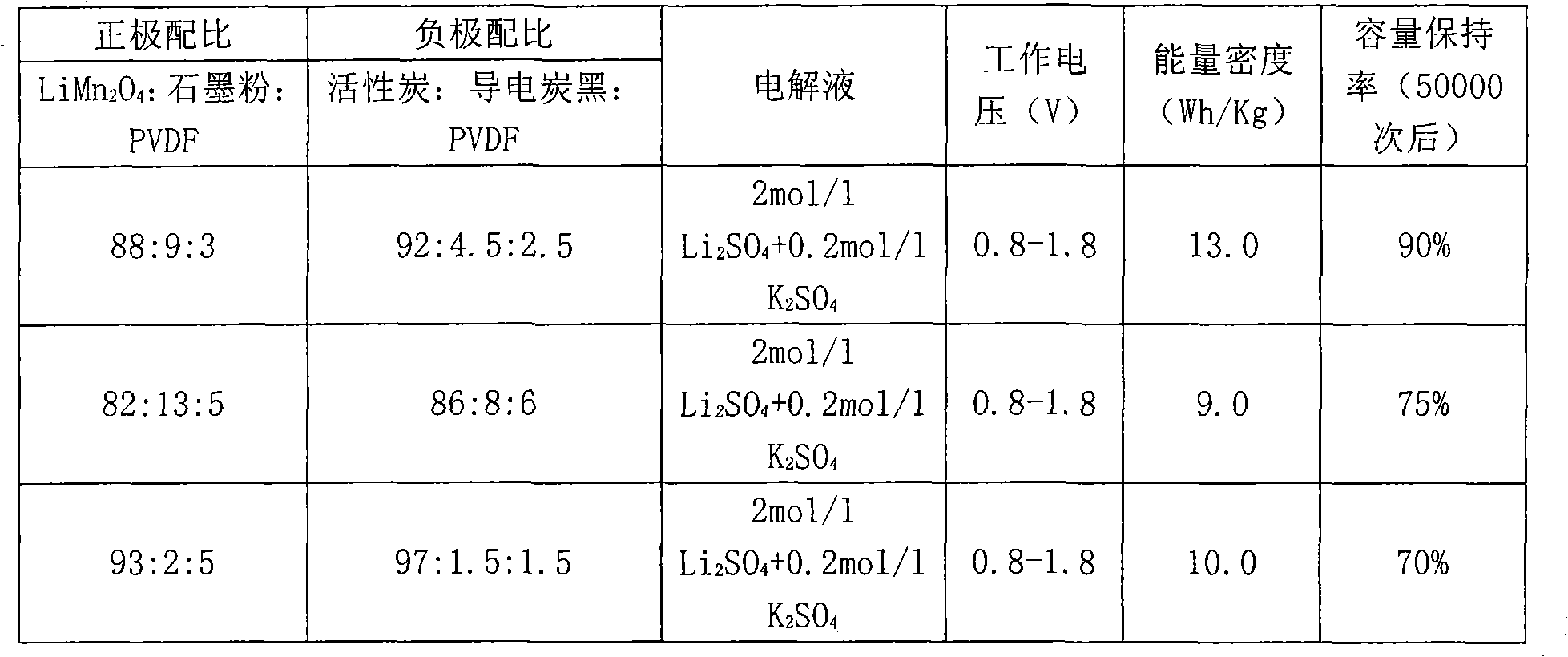

[0034] Example 1: Production of positive electrode sheet: LiMn 2 O 4、Graphite powder and PVDF are mixed according to the mass ratio of 88:9:3, adjusted into slurry with NMP (1-methyl-2-pyrrolidone), then coated on the burr steel strip, dried (120~130℃), Rolled and cut pieces into a size of 150*90*0.5mm 3 , And spot-weld the tabs. The production of the negative electrode sheet: the activated carbon, conductive carbon black, and PVDF are mixed in a mass ratio of 92:4.5:2.5, adjusted into a slurry with NMP, and then coated on the burr steel strip, dried (120~130℃), and rolled , The cut piece is made into a size of 150*90*1.6mm 3 , And spot weld on the tab. Select polyethylene microporous film as the diaphragm, stack the positive electrode sheet (18 pieces), the diaphragm, and the negative electrode sheet (19 pieces) into the electric core, use the 80,000F shell to assemble the square capacitor, and inject 2mol / l Li 2 SO 4 600g aqueous solution, and then refer to the automotive superc...

Embodiment 2

[0035] Example 2: Production of positive electrode sheet: LiMn 2 O 4 、Graphite powder and PVDF are mixed according to the mass ratio of 88:9:3, adjusted into slurry with NMP (1-methyl-2-pyrrolidone), then coated on the burr steel strip, dried (120~130℃), Rolled and cut pieces into a size of 150*90*0.5mm 3 , And spot-weld the tabs. The production of the negative electrode sheet: the activated carbon, conductive carbon black, and PVDF are mixed in a mass ratio of 92:4.5:2.5, adjusted into a slurry with NMP, and then coated on the burr steel strip, dried (120~130℃), and rolled , The cut piece is made into a size of 150*90*1.6mm 3 , And spot weld on the tab. Choose polyethylene microporous membrane as the diaphragm, stack the positive electrode sheet (18 pieces), the diaphragm, and the negative electrode sheet (19 pieces) into the electric core, and use the 80,000F shell to assemble the square capacitor, and inject (2mol / l Li 2 SO 4 +0.2mol / lK 2 SO 4 ) 600g of mixed solution, and then...

Embodiment 3

[0039] Example 3: Production of positive electrode sheet: LiMn 2 O 4 , Graphite powder and PVDF are mixed according to the mass ratio of 82:13:5, and NMP (1-methyl-2-pyrrolidone) is used to prepare a slurry, and then coated on the burr steel strip, after drying (120~130℃), Rolled and cut pieces into a size of 150*90*0.5mm 3 , And spot-weld the tabs. The production of the negative electrode sheet: The activated carbon, conductive carbon black, and PVDF are mixed at a mass ratio of 86:8:6, and NMP is used to adjust the slurry, and then coated on the burr steel strip, dried (120~130℃), and rolled , The cut piece is made into a size of 150*90*1.6mm 3 , And spot weld on the tab. Choose polyethylene microporous membrane as the diaphragm, stack the positive electrode sheet (18 pieces), the diaphragm, and the negative electrode sheet (19 pieces) into the electric core, and use the 80,000F shell to assemble the square capacitor, and inject (2mol / l Li 2 SO 4 +0.2mol / l K 2 SO 4 ) 600g of mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com