Preparation method of fermented feed rich in probiotics

A technology for fermented feed and probiotics, applied in animal feed, animal feed, applications, etc., can solve the problems of limited production capacity, backward production technology of fermented feed, high production cost and energy consumption, and achieve the content of probiotics and the number of viable bacteria. The effect of improving, high target product generation rate, and improving equipment utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Bacterial species: Bacillus natto (Bacillus natto) strain, the preservation number is CGMCC No.2236.

[0015] 2. Medium and culture conditions:

[0016] Incline medium: beef extract 0.5g, peptone 1g, NaCl 0.5g, agar 2g, water 100mL, pH7.0-7.2, culture at 37°C for 12h.

Embodiment 2

[0018] 1, bacterial classification, slope culture are the same as embodiment 1

[0019] 2. Seed medium and culture conditions:

[0020] Seed medium: peptone 1g, glucose 2g, K 2 HPO 4 0.1g, MgSO 4 0.05g, water 100mL, pH7.0-7.2, 37°C, 200r / min shaking culture for 16h.

Embodiment 3

[0022] 1, bacterial classification, slope culture are the same as embodiment 1

[0023] 2, seed culture is the same as embodiment 2

[0024] 3. Main detection methods

[0025] Determination of protein content: Folin-phenol method

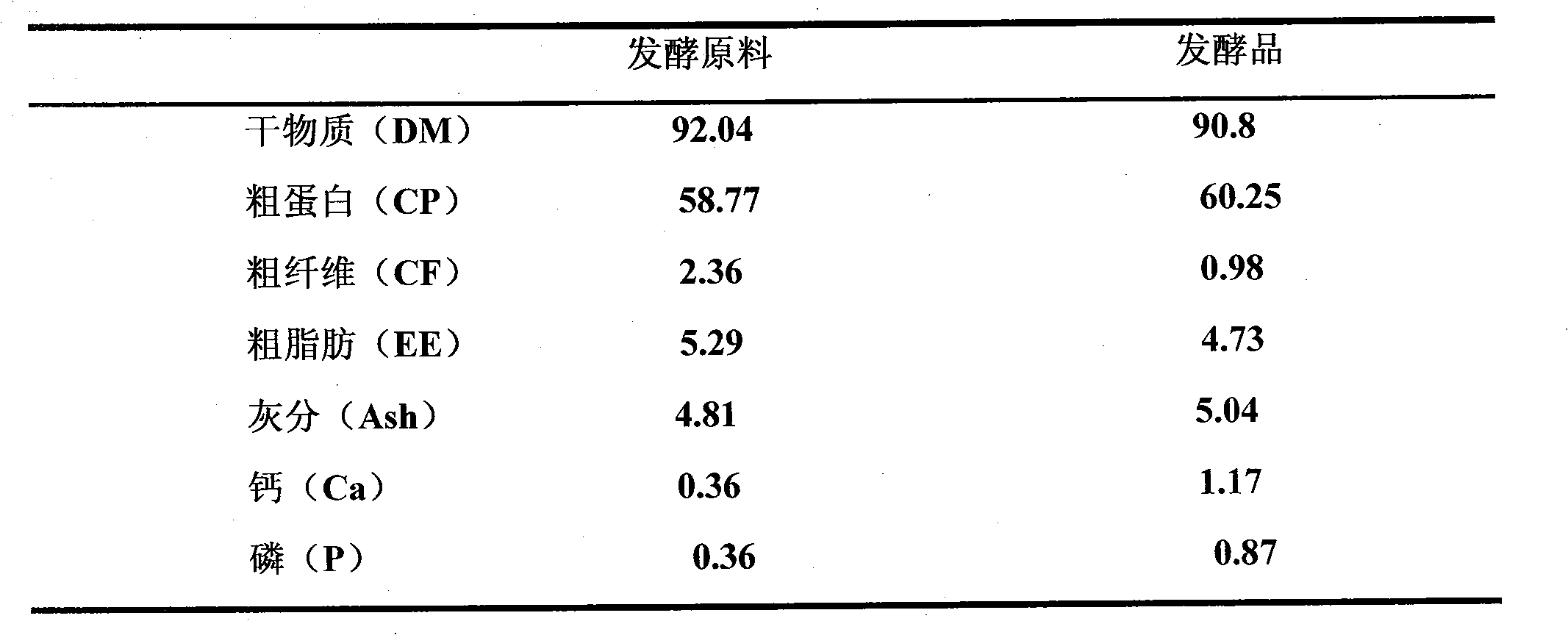

[0026] 4. Determination of thick mash fermentation medium: use single factor experiment method to study the effect of the ratio of corn flour, bran and soybean meal, the ratio of medium dry base to water and the ratio of medium dry base to nutrient salt on the protein content, and determine The optimum dry base composition of fermentation culture is as follows: corn gluten meal, soybean meal and bran are mixed in a ratio of 16:3:1; the ratio of medium dry base to water is 1:3.5; CaHPO 4 The ratio to the dry base of the medium is 0.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com