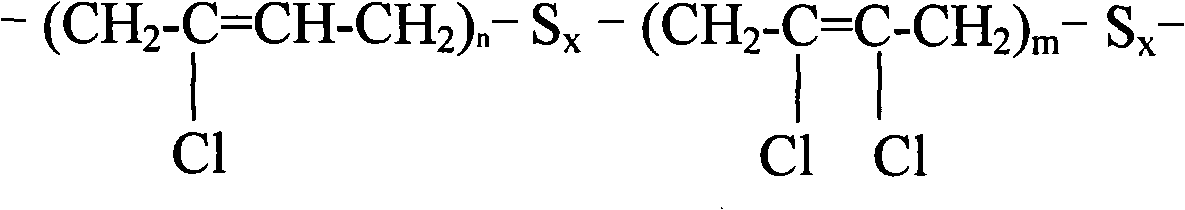

Sulfur-modified neoprene, method for preparing same and applications

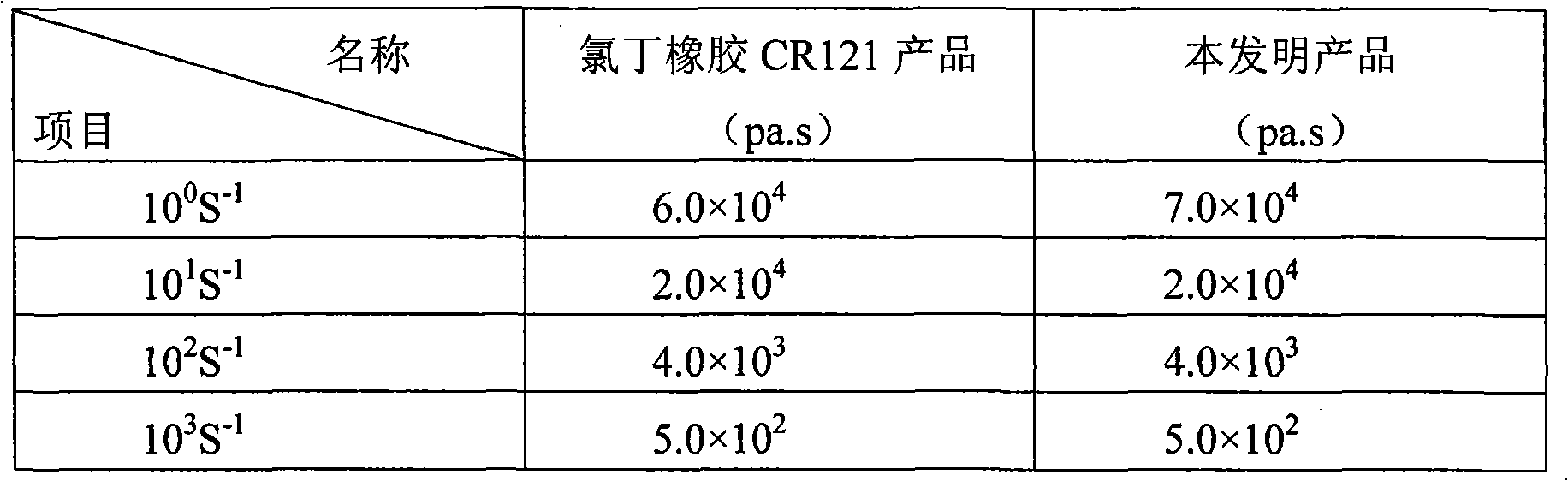

A neoprene, sulfur-adjusted technology, applied in mechanical equipment, transmission belts, V-belts, etc., can solve the problems of low tensile strength, poor flexural crack resistance, poor Mooney viscosity stability, etc., to improve processing performance , good mechanical properties and processing properties, the effect of improving structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: a kind of sulfur adjustment type chloroprene rubber, it is characterized in that it is the copolymer of chloroprene, 2,3-dichlorobutadiene and sulfur, each component distribution ratio and terminator in its polymerization reaction The group distribution ratio is shown in Table 5.

[0049] Each component distribution ratio (by weight) of polymerization reaction in the embodiment 1 of table 5

[0050]

[0051] The preparation method of above-mentioned sulfur adjustment type chloroprene rubber, it may further comprise the steps:

[0052] a, at first according to the proportioning of table 5, each component in the oil phase is chloroprene, 2,3-dichlorobutadiene, regulator sulfur and disproportionated rosin are mutually dissolved completely, and according to the proportioning of table 5, the water The components in the phase, that is, co-emulsifier sodium petroleum sulfonate and sodium lauryl sulfate, dispersant sodium alkylnaphthalene sulfonate, sodium hyd...

Embodiment 2

[0057] Example 2: A sulfur-adjusted chloroprene rubber, wherein the distribution ratio of each component in the polymerization reaction and the component distribution ratio of the terminator are shown in Table 6.

[0058] Each component distribution ratio (by weight) of the polymerization reaction in the embodiment 2 of table 6

[0059]

[0060] The preparation method of the above-mentioned sulfur-modified chloroprene rubber, wherein the polymerization reaction temperature is 20-25 ° C, and the rest are the same as in Example 1.

[0061] The weight-average molecular weight of the above-mentioned sulfur-adjusted chloroprene rubber is 107341, and the number-average molecular weight is 53538, which are determined by the same method and standard as in Example 1. In addition, the brittleness temperature measured by GB / T 15256-1994 low-temperature brittleness of vulcanized rubber is -40°C.

Embodiment 3

[0062] Embodiment 3: A sulfur-adjusted chloroprene rubber, wherein the distribution ratio of each component in the polymerization reaction and the component distribution ratio of the terminator are shown in Table 7.

[0063] Each component distribution ratio (by weight) of the polymerization reaction in the embodiment 3 of table 7

[0064]

[0065]

[0066] The preparation method of the above-mentioned sulfur-modified chloroprene rubber, wherein the polymerization reaction temperature is 25-30° C., and the rest are the same as in Example 1.

[0067] The weight-average molecular weight of the above-mentioned sulfur-adjusted chloroprene rubber is 136258, and the number-average molecular weight is 62849, which are determined by the same method and standard as in Example 1. In addition, according to GB / T 15256-1994 measurement standard of low-temperature brittleness of vulcanized rubber, the brittleness temperature is -41°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com