High humidity vinegar residue resource processing method

A treatment method and a resource-recycling technology, which are applied in the field of high-humidity vinegar lees resource treatment and waste residue utilization, can solve the problems of waste of resources, difficulty in improving treatment capacity and treatment efficiency, and complicated processes, and achieve the elimination of odor and acidity. The effect of volume reduction and space resource reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

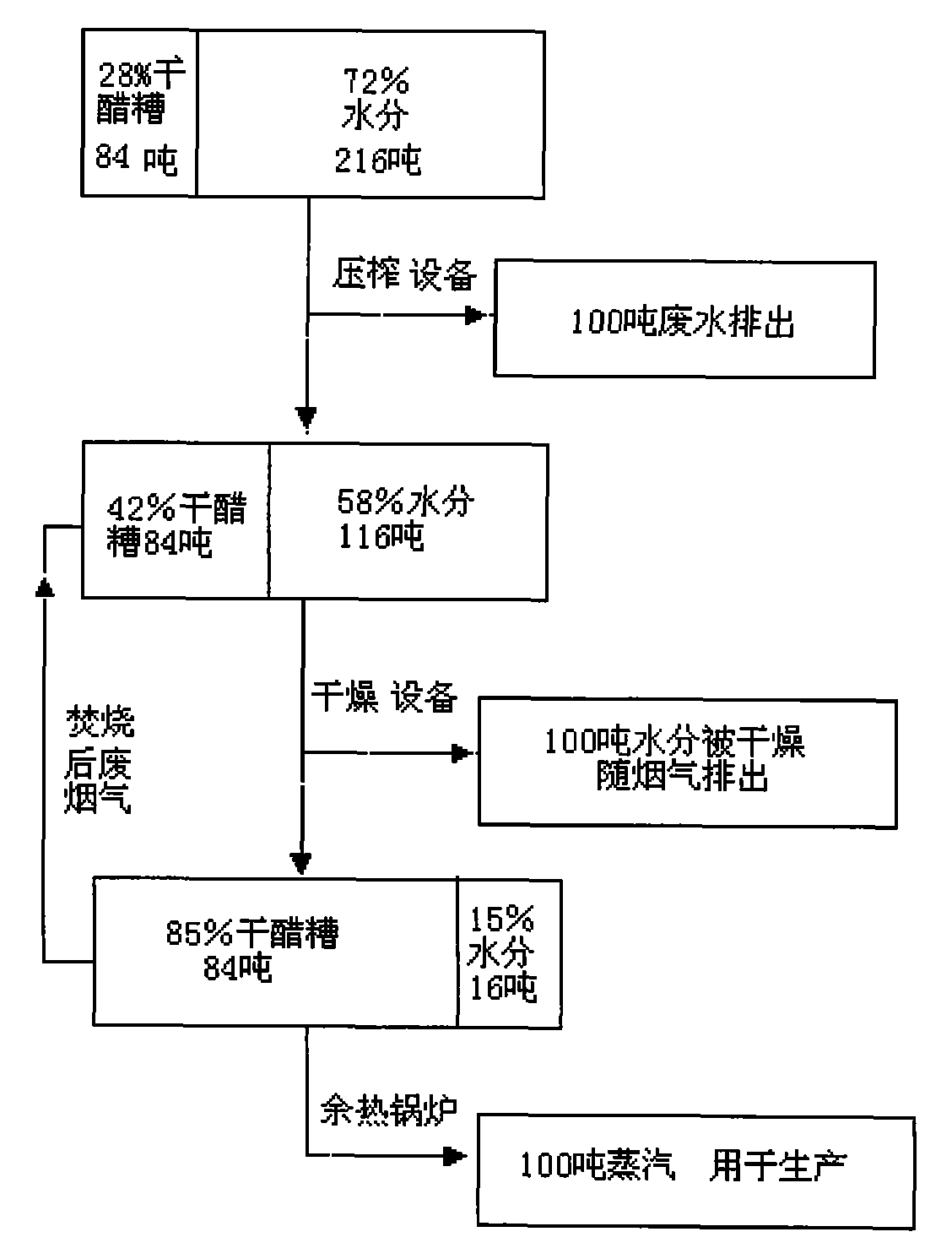

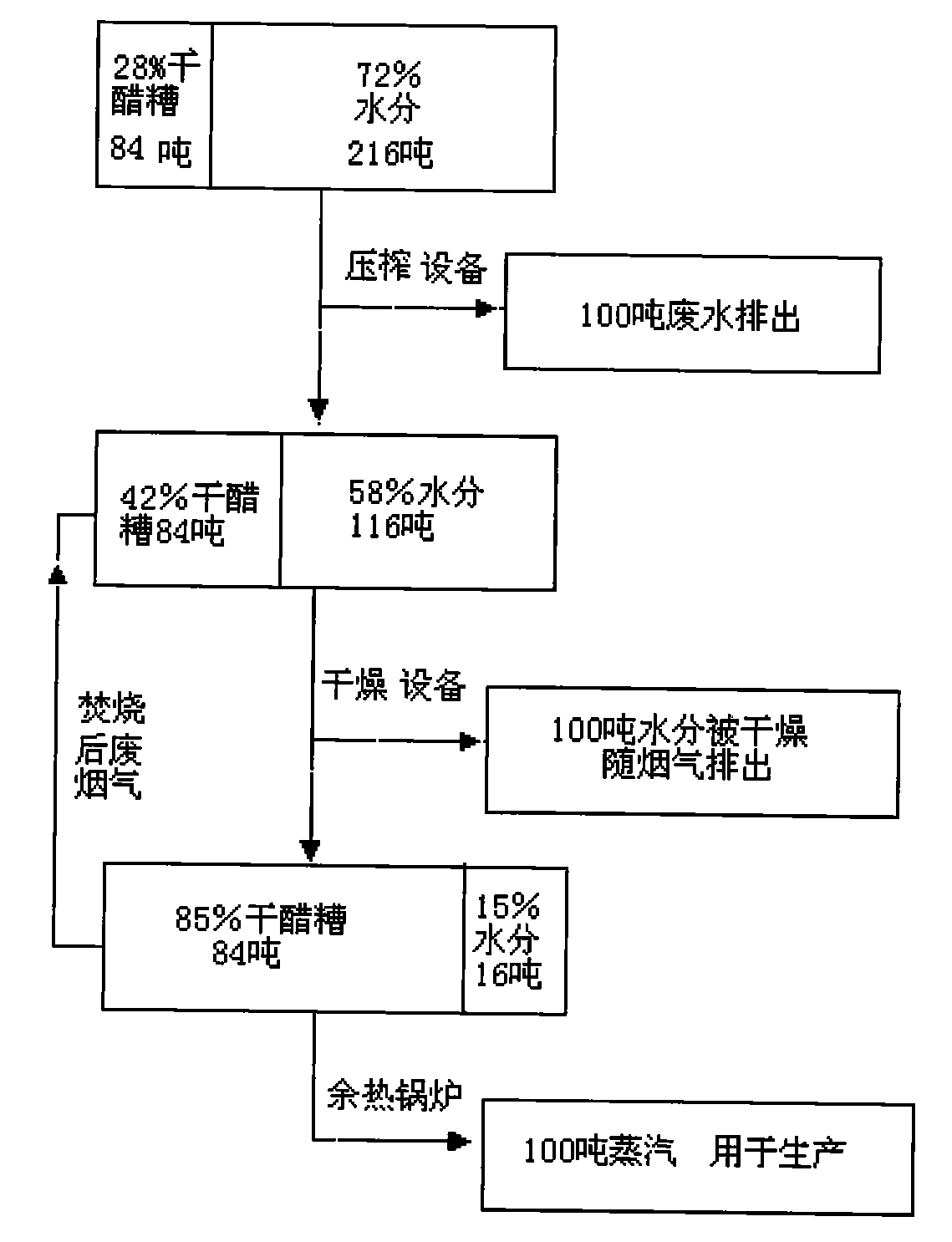

[0019] Above purpose is achieved like this, and its feature is illustrated with the example of handling 300 tons of vinegar grains. The treatment process includes a drying process, an incineration process, and the steps are as follows:

[0020] 1. Drying process. The vinegar grains after the preliminary dehydration enter the drying equipment to dry and remove water. At this time, the remaining 200 tons of vinegar grains contain 84 tons of 42% dry vinegar grains and 116 tons of 58% moisture. Direct heat to dry. The required drying energy is provided by the high-temperature flue gas generated in the incineration process, and the dry moisture is also taken away by the flue gas. Through the exhaust gas control equipment, the temperature of the flue gas is controlled at 300 degrees Celsius when it enters the drying equipment, and it is controlled at 60 degrees Celsius after drying, and the moisture taken away by the flue gas reaches 100 tons. Like this, the moisture content (dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com