Forming method and device of hollow fiber blood filtering membrane

A blood filtration and fiber technology, applied in chemical instruments and methods, blood filtration, membrane technology, etc., can solve the problems of inconsistent wall thickness of the filter membrane, uneven wall thickness of the hollow fiber membrane, and poor surface finish of the filter membrane. Achieve good chemical stability, uniform micropore size and good spinnability

Inactive Publication Date: 2010-08-11

张亚琴

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when making hollow fiber membranes at home and abroad, the flow of spinning liquid is controlled by metering pumps. This spinning method has the following problems: 1. The wall thickness of the hollow fiber membranes is not uniform.

Due to the small diameter of the hollow fiber membrane, whether the metering pump used is a gear pump or a plunger pump, the output liquid will pulsate during operation, and this pulsation will cause pressure pulsation, resulting in the liquid being sent to the spinneret. The flow rate and pressure of the spinning solution often change, so the wall thickness of the filter membrane made by the spinning solution from the spinneret cannot be kept consistent, and the surface finish of the filter membrane is not high, resulting in uneven pore size of the filter membrane , resulting in low clearance rate of the filter membrane, so the hollow fiber membrane made of it is not ideal for hemodialysis

On the other hand, due to the pulsation of the spinning liquid supply, the continuity of spinning is reduced, so the yield of the filter membrane is low, which increases the manufacturing cost

2. The clearance rate of the hollow fiber membrane is low

3. It is not easy to realize industrialized production

The current hollow fiber blood filtration membrane is formed by using a metering pump for a container and feeding a double-hole spinneret. Due to the reduced production efficiency, it is difficult to realize industrial production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Login to View More

Abstract

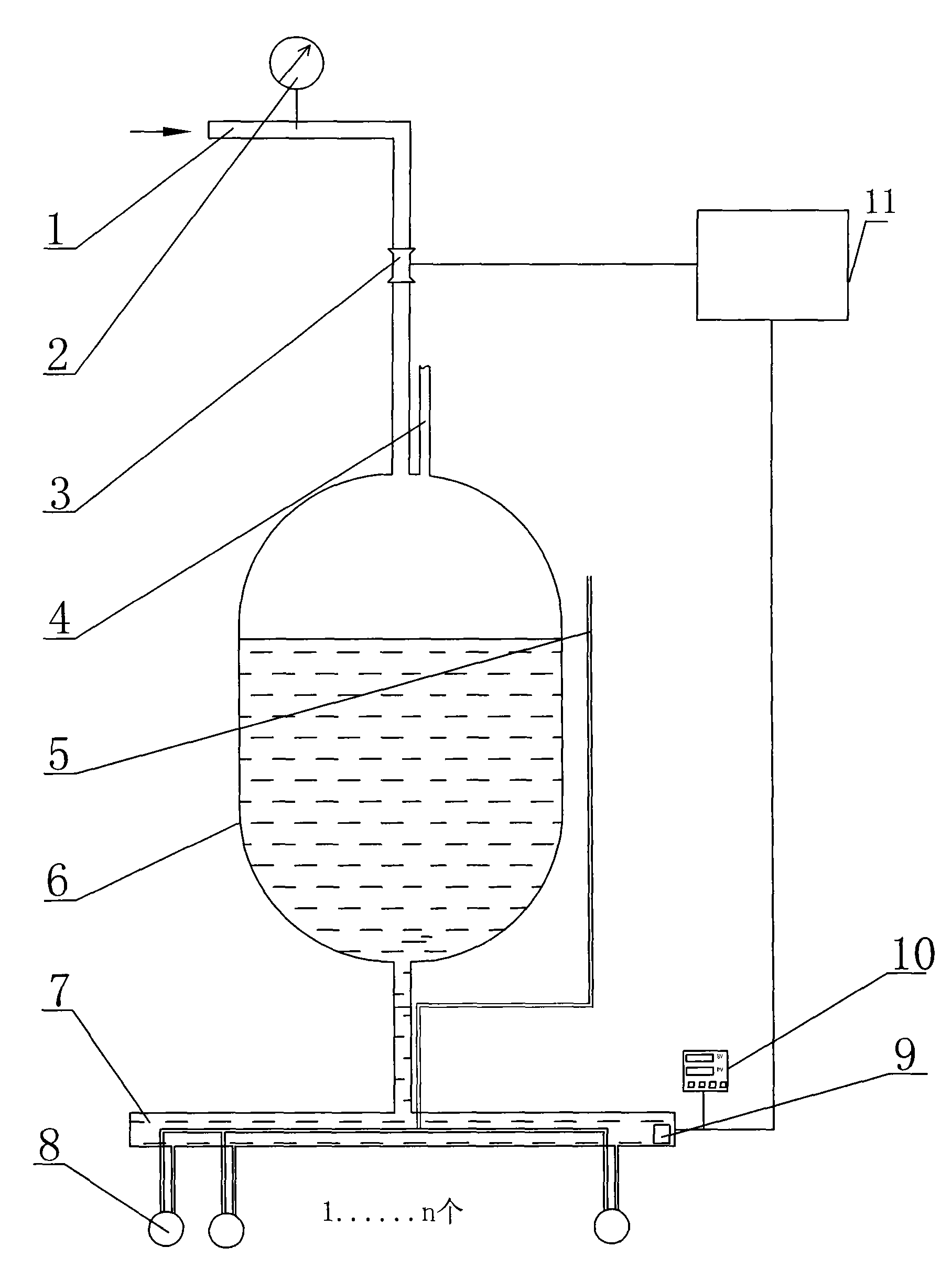

The invention relates to a forming method of a hollow fibre blood filter film; spinning solution with given rotation viscosity is delivered to a sealed container; clean gas with the pressure of 0.01-0.10MPa is pumped into the container; the spinning solution is sprayed out of an external hole of a dual-hole spinneret with the flux of 0.1-10ml / min through a distribution pipe that is horizontally arranged under the gas pressure; the filling liquid is sprayed out of an internal hole with the flux of 0.05-5ml / min under the pressure of 0.01-0.10MPa; after being solidified by air, the primary fibreenters water bath and is solidified, formed and wound to gain the filter film; meanwhile, a pressure sensor feeds the fluid pressure signals at the distribution pipe back to a controller which controls the air inlet pressure of the container, thus keeping stable liquid outlet flux of the dual-hole spinneret. The forming method of the invention keeps stable liquid outlet flux of the dual-hole spinneret by controlling the pressure in the container, which has simple technology, uniform and smooth film wall of the product and good continuity, and facilitates the industrialized production.

Description

technical field The invention relates to a method for forming a hollow fiber blood filtration membrane and a device thereof, and belongs to the technical field of fiber membrane production. Background technique Polyethersulfone or polysulfone is a special engineering plastic, because of its high glass transition temperature, stable physical and chemical properties, and after years of improvement and perfection, it is currently one of the main materials for blood purification membranes. The hollow fiber membrane made of polyethersulfone or polysulfone has the characteristics of non-toxicity, resistance to disinfection by various methods, excellent biocompatibility, and better removal than ordinary hollow fiber membranes. However, the requirements for the production of hollow fiber membranes for hemodialysis are higher than those of ordinary hollow fiber membranes. Not only does the hollow fiber membrane have a suitable inner and outer diameter ratio, but it also requires a un...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D71/68A61M1/34

Inventor 张亚琴

Owner 张亚琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com