Earth silicon vesicle material with controllable shape, dimension and thickness of wall and method for preparing same

A technology of silica and vesicles, applied in the field of porous materials, to achieve the effects of simple operation, rich structure, great possibility and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

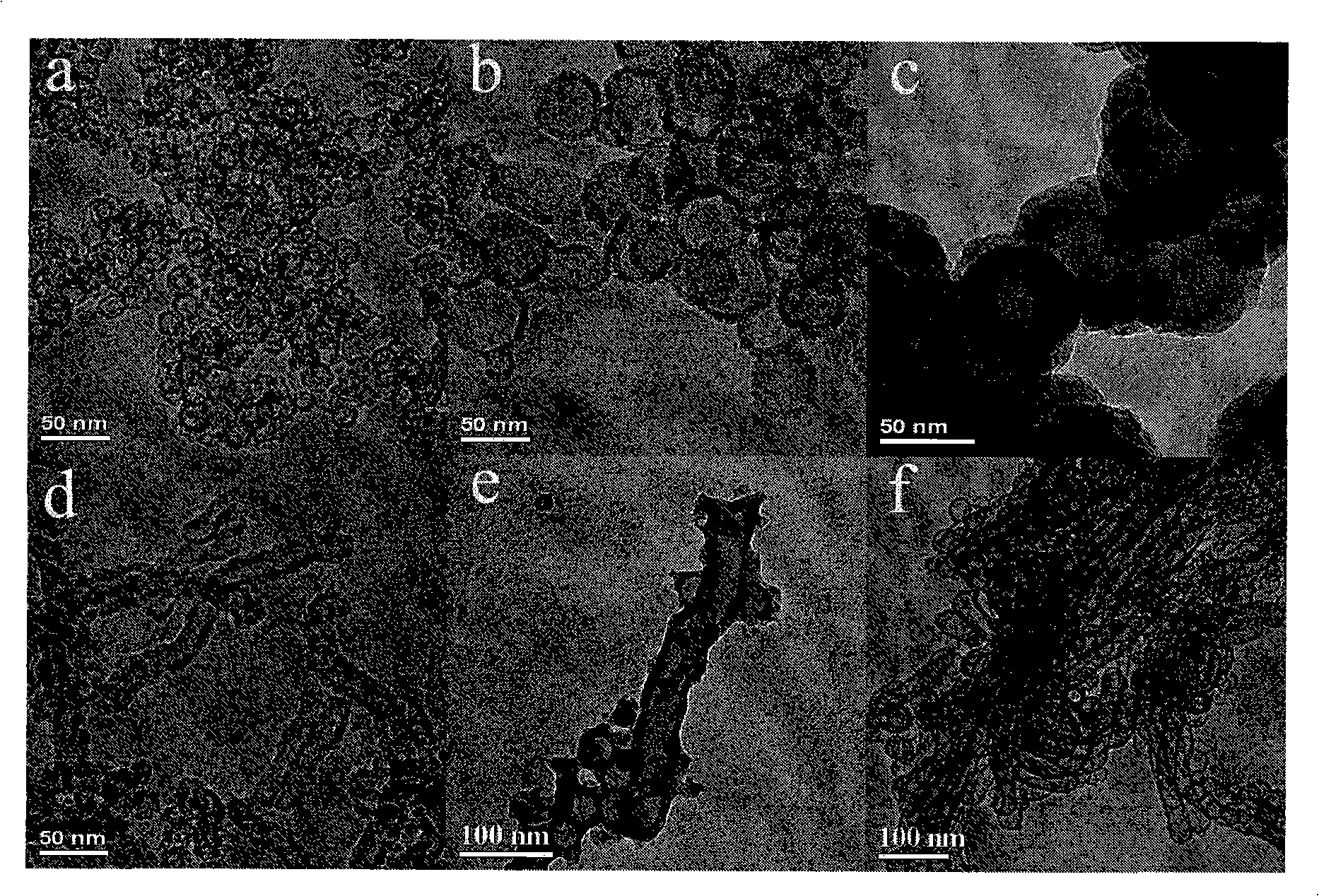

[0030] Add 0.2g B50-6600 and 0.3g P65 mixed surfactant into 30g pH=4.7NaAC-HAc[c(HAc)=c(NaAc)=0.4M] buffer solution, stir at 25°C to make the surfactant Dissolve completely, add 0.008mol TEOS and 0.002mol TMOS mixed silicon source to the system, continue to stir for 40 minutes, let stand for 24 hours, heat at 100°C for 24 hours, suction filter, wash, dry, and bake at 550°C for 5 hours. get figure 1 (a) Shaped vesicle material.

Embodiment 2

[0032] Add 0.5g B50-6600 into 30g pH=4.7NaAC-HAc[c(HAc)=c(NaAc)=0.4M] buffer solution, stir at 25°C to completely dissolve the surfactant, add 2.08 g TEOS, continue to stir for 20 minutes, let stand for 24 hours, heat at 100°C for 24 hours, filter with suction, wash, dry, and bake at 550°C for 5 hours. get figure 1 (b) Shaped vesicle material.

Embodiment 3

[0034] Add 0.5g B50-6600 mixed surfactant into 30g pH=4.7NaAC-HAc[c(HAc)=c(NaAc)=0.4M] buffer solution, stir at 25°C to completely dissolve the surfactant, and add Add 0.01mol TEOS and 0.004mol TMOS mixed silicon source into the system, continue to stir for 40 minutes, let stand for 24 hours, heat at 100°C for 24 hours, suction filter, wash, dry, and bake at 550°C for 5 hours. get figure 1 (c) Vesicle-like material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com