Carbonate molten heat transmission and thermal storage medium, preparation thereof and applications

A technology of carbonate molten salt and heat storage medium, which is applied in chemical instruments and methods, heating devices, solar thermal devices, etc., can solve rare and other problems, and achieve the goal of improving heat storage capacity, widening the working temperature range, and large latent heat of phase change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix sodium chloride and potassium chloride with a mass ratio of 0.1:1 and stir evenly, statically heat until the solids are completely melted, keep the temperature for 10 minutes, and then naturally cool to room temperature to obtain the additive.

[0034] 37% by mass of potassium carbonate, 53% of sodium carbonate, and 10% of the additives were mixed and stirred evenly, heated statically until the solids were completely melted, then kept warm for 10 minutes, and then naturally cooled to room temperature to obtain the modified Molten salt heat transfer heat storage medium.

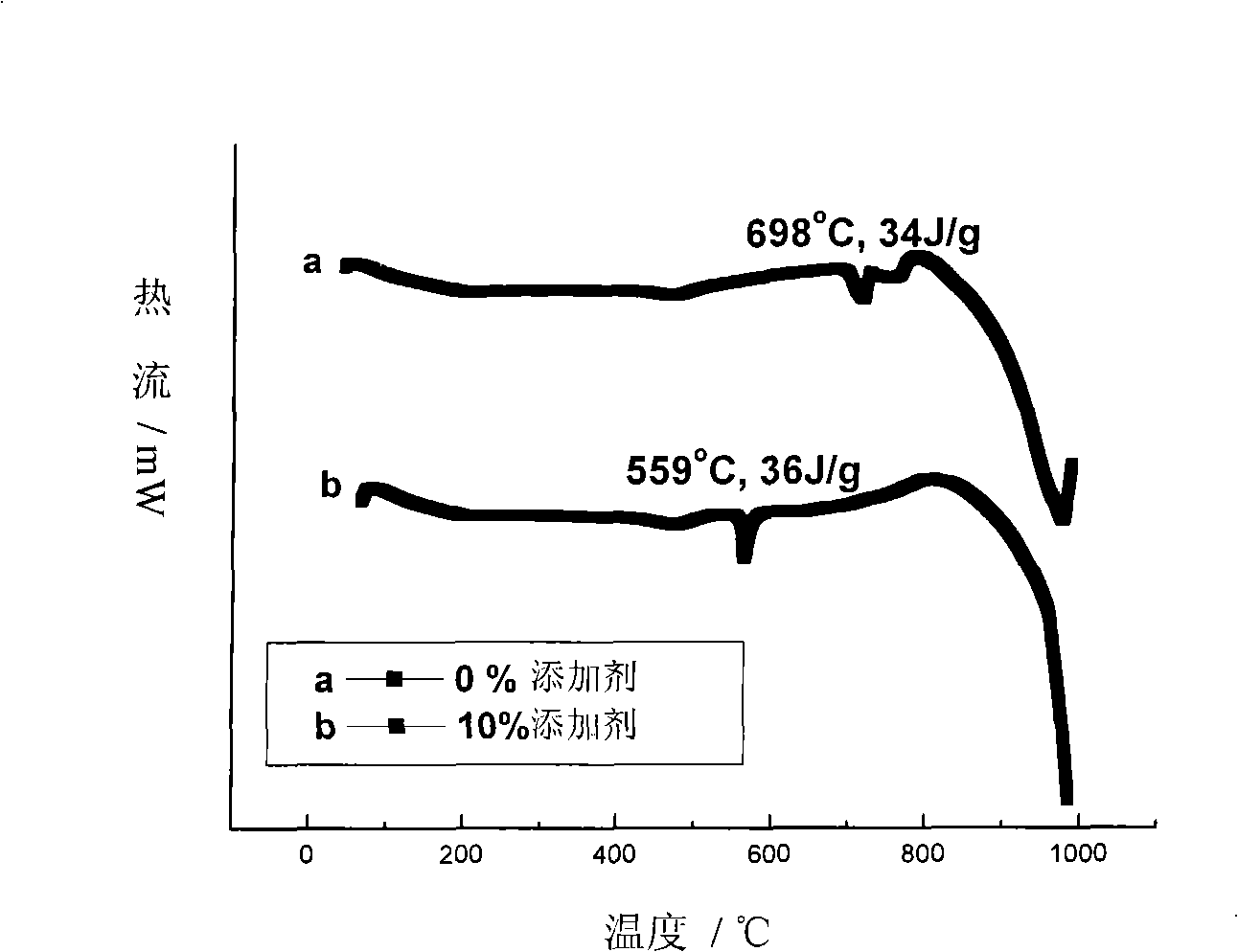

[0035] The melting point and latent heat of phase change of the prepared carbonate molten salt were tested. The test is carried out with a general-purpose differential scanning (DSC) instrument. The DSC curve obtained from the test is as follows figure 1 Shown in curve b. Adopt the same method to test the unmodified molten salt, the DSC curve obtained by the test is as follows figure 1 As shown ...

Embodiment 2

[0040] Mix sodium chloride and potassium chloride with a mass ratio of 0.6:1 and stir evenly, statically heat until the solids are completely melted, keep the temperature for 30 minutes, and then naturally cool to room temperature to obtain the additive.

[0041] Mix 45% potassium carbonate, 39% sodium carbonate, and 16% of the additive by mass and stir evenly, heat statically until the solids are completely melted, then keep the temperature for 10 minutes, and then cool naturally to room temperature to obtain the modified Molten salt heat transfer heat storage medium.

[0042] The melting point and latent heat of phase change of molten salt are tested. Test method is the same as embodiment 1. The test results show that the melting point of the modified molten salt does not change much compared with Example 1, and the latent heat of phase change increases to a large extent.

[0043] The thermal stability performance of molten salt media was tested. Test method is the same a...

Embodiment 3

[0045] Mix sodium chloride and potassium chloride with a mass ratio of 0.2:1, stir evenly, heat statically until the solids are completely melted, keep the temperature for 15 minutes, and cool naturally to room temperature to obtain the additive.

[0046] Mix 34% potassium carbonate, 46% sodium carbonate, and 20% of the additive by mass and stir evenly, heat statically until the solids are completely melted, then keep the temperature for 10 minutes, and then cool naturally to room temperature to obtain the modified Molten salt heat transfer heat storage medium.

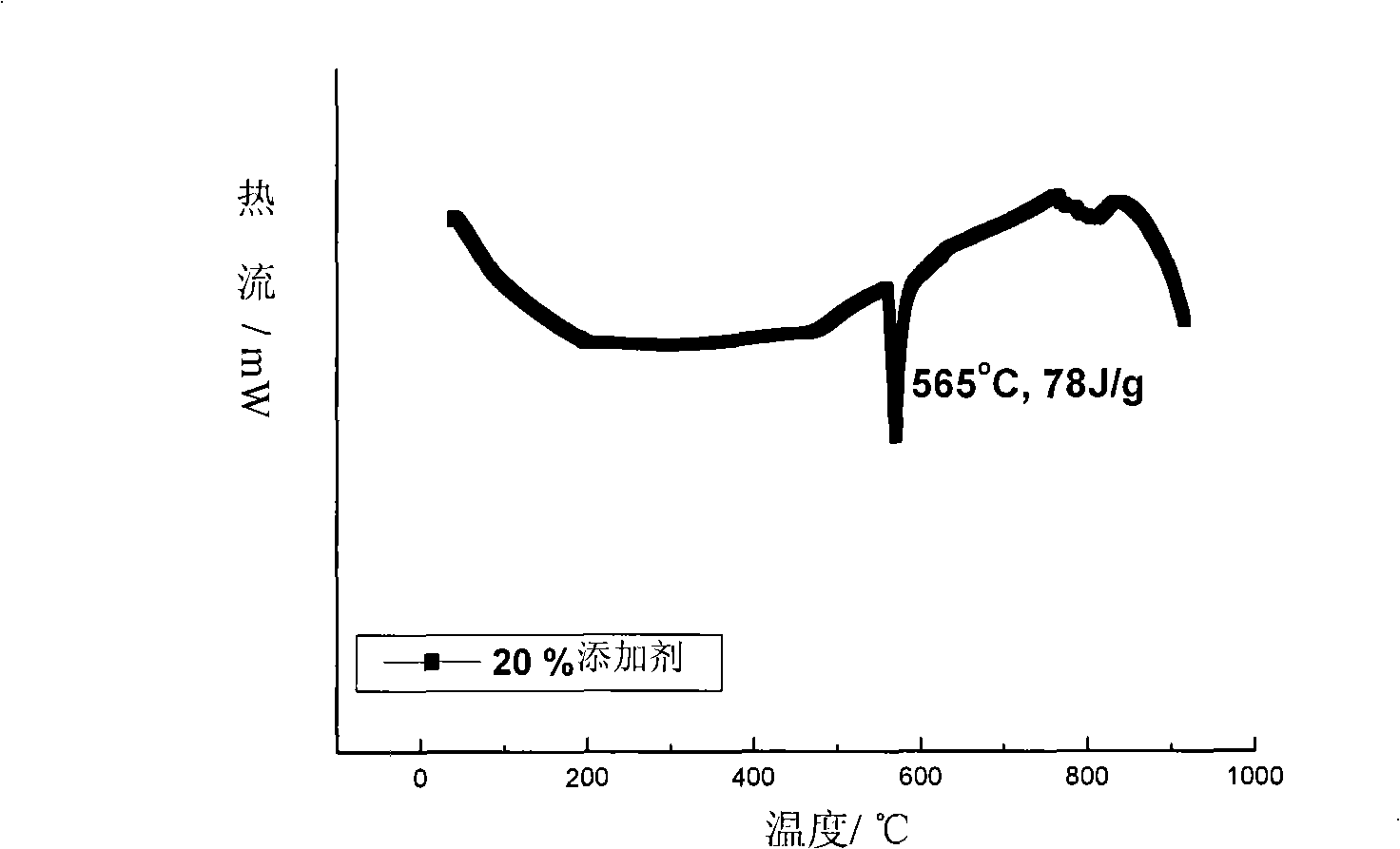

[0047] The melting point and latent heat of phase change of molten salt are tested. Test method is the same as embodiment 1. The DSC curve of the test is as figure 2 shown. The results show that the melting point of the modified molten salt prepared in this example does not change much compared with Example 1, and the latent heat of phase change increases to a greater extent than Example 2, reaching 78J / g.

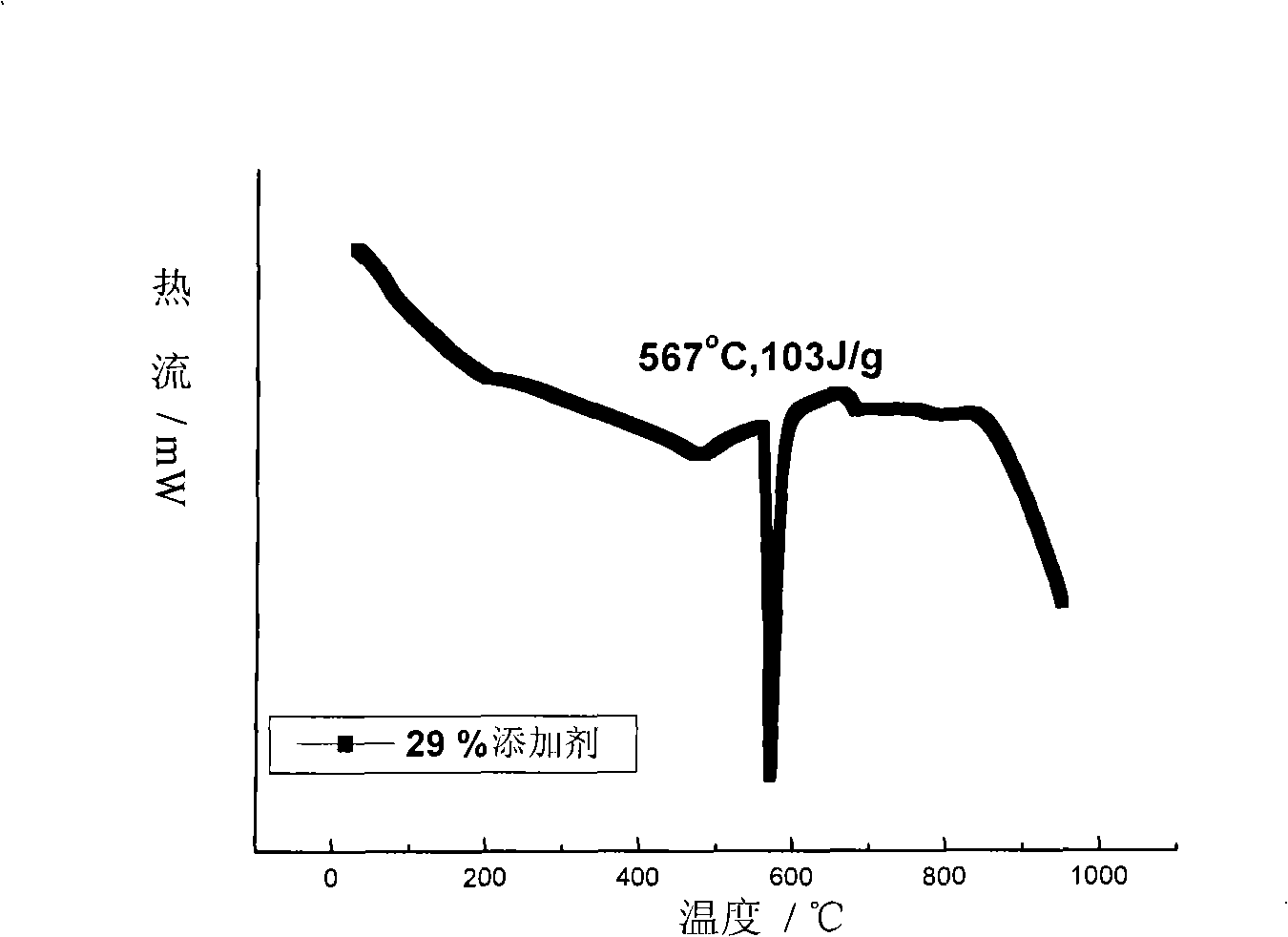

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com