Copper recovery form etching waste liquid of circuit board

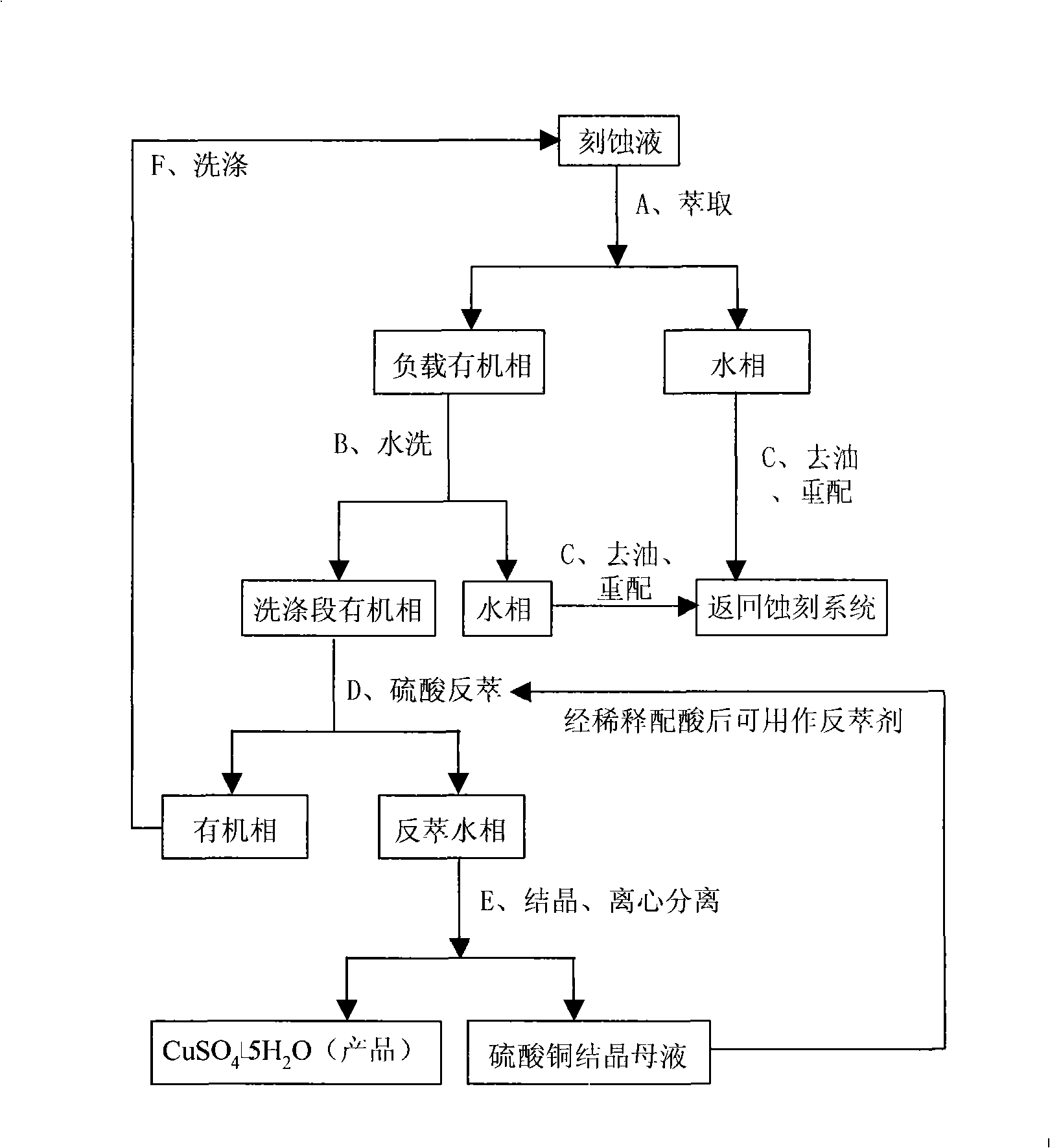

A recovery method and a technology for etching waste liquid are applied in the field of copper recovery in waste liquid to achieve good economic and environmental benefits, simplify processes and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

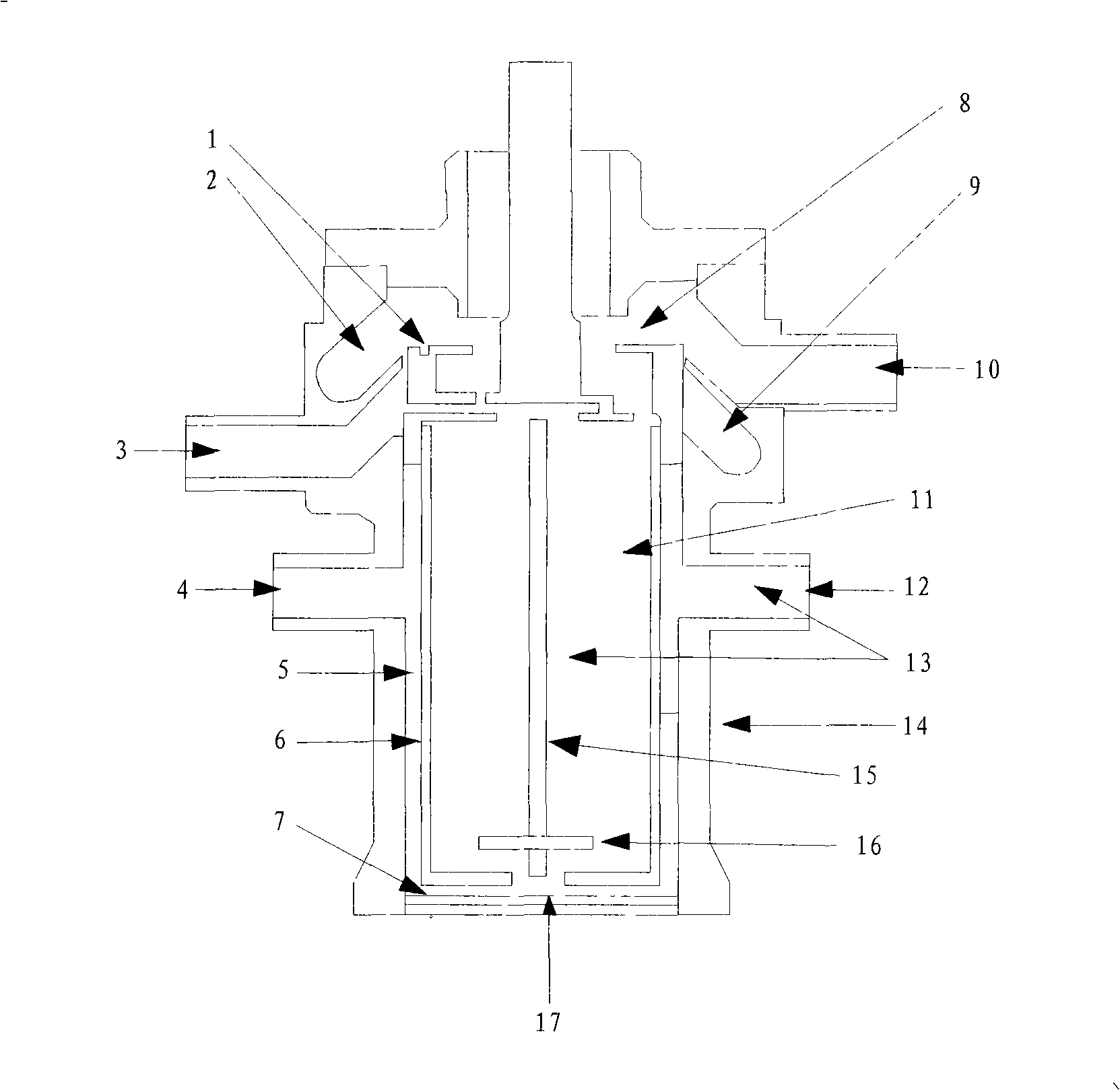

example 1

[0051] Using 50% N910 kerosene solution as the extraction agent, the extraction ratio O / A=3.6 / 1, the etching solution is extracted on a Φ20 centrifugal extractor for 5 stages, and the etching solution and the organic phase are pumped proportionally by metering pumps Put into the extractor and carry out continuous extraction, the loading capacity of outlet organic phase copper is 22.5 g / liter, carry out 2 grades of water washings with loading organic phase, wash away chloride ion; In the water phase, copper ion concentration is 0.087 g / L, and the water phase further After degreasing with glass fiber and activated carbon, it can be used as etching solution again. Heat the loaded organic phase to 55°C, use 5M sulfuric acid to stir and strip for 20 minutes under the condition of O / A=2.4 / 1, stop stirring; carry out phase separation under heat preservation conditions, and analyze the organic phase and strip water respectively Phase copper ion concentration, obtains its back extracti...

example 2

[0054] Using 50% N902 kerosene solution as the extraction agent, the extraction ratio O / A=3.5 / 1, the etching solution is extracted on a Φ20 centrifugal extractor for 5 stages, and the etching solution and the organic phase are pumped proportionally by metering pumps Put into the extractor and carry out continuous extraction, the loading capacity of outlet organic phase copper is 26.2 grams / liter, carries out 2 grades of water washings with load organic phase, washes away chloride ion; In the water phase, copper ion concentration is 0.089 grams / liter, and the water phase further After degreasing with glass fiber and activated carbon, it can be used as etching solution again. The loaded organic phase was heated to 600C, and the crystallization mother liquor obtained by using Example 1 was formulated into a copper-containing 10 g / liter 5M sulfuric acid solution, stirred and stripped for 20 minutes under the condition of O / A=2.2 / 1, and stopped stirring; Carry out phase separation ...

example 3

[0057] Using 50% M5640 kerosene solution as the extraction agent, the extraction ratio O / A=3.2 / 1, the etching solution is extracted on a Φ2 centrifugal extractor for 5 stages, and the etching solution and the organic phase are pumped proportionally by metering pumps Put into the extractor and carry out continuous extraction, the loading capacity of outlet organic phase copper is 23.2 g / liter, carry out 2 grades of water washings with loading organic phase, wash away chloride ion; In the water phase, copper ion concentration is 0.075 g / L, and the water phase further After degreasing with glass fiber and activated carbon, it can be used as etching solution again. Heat the loaded organic phase to 50°C, use 5M sulfuric acid solution containing 10 g / L, stir and back-extract for 30 minutes under the condition of O / A=2.2 / 1, stop stirring; carry out phase separation under heat preservation conditions, The concentration of copper ions in the organic phase and the stripped water phase w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com