Mixed flow type atomizing propulsion aeration cooling tower

A ventilation cooling, mixed-flow technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc. Improvement and other problems to achieve the effect of optimizing the cooling effect, increasing the air volume, and reducing the resistance of the air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

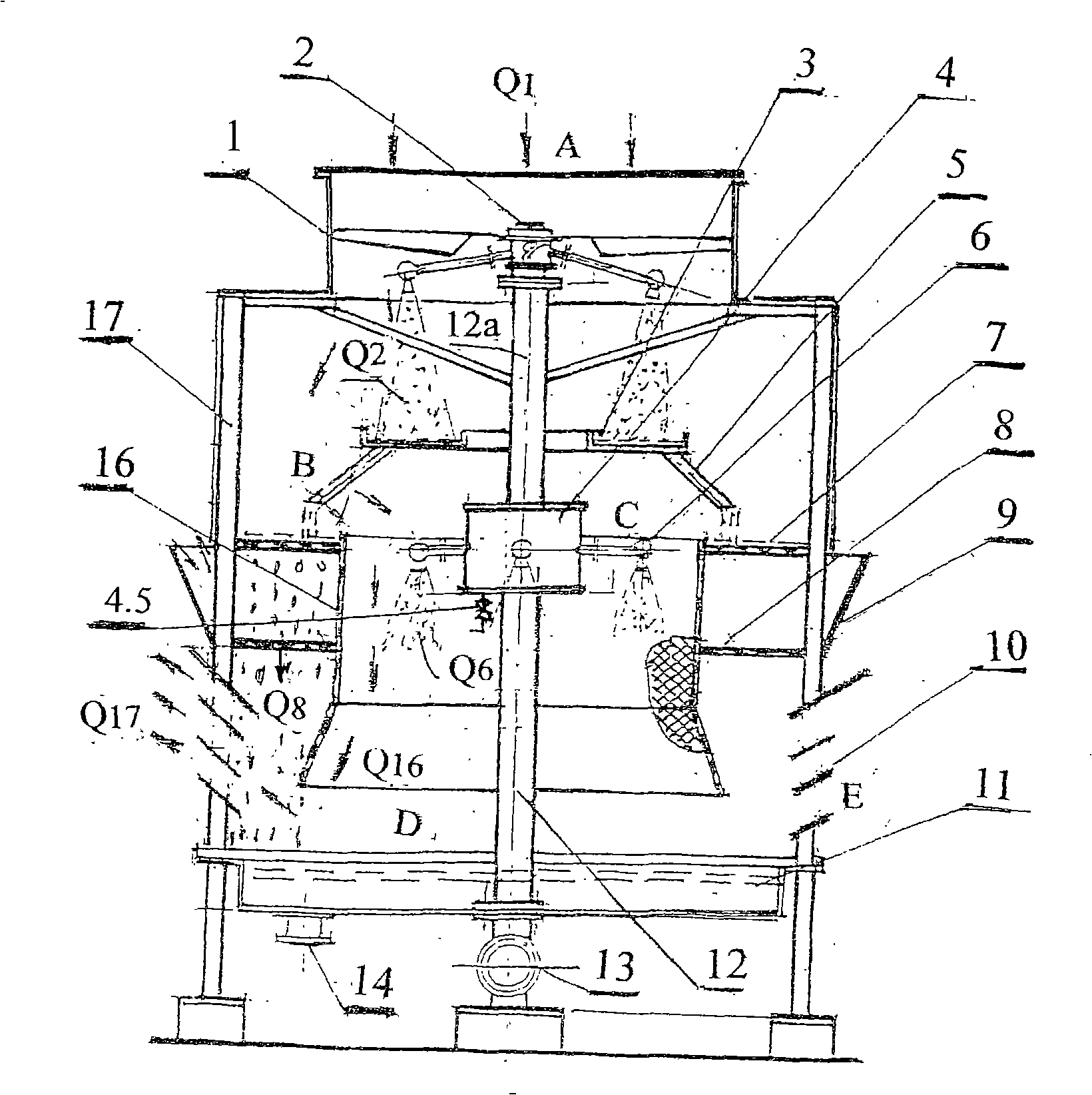

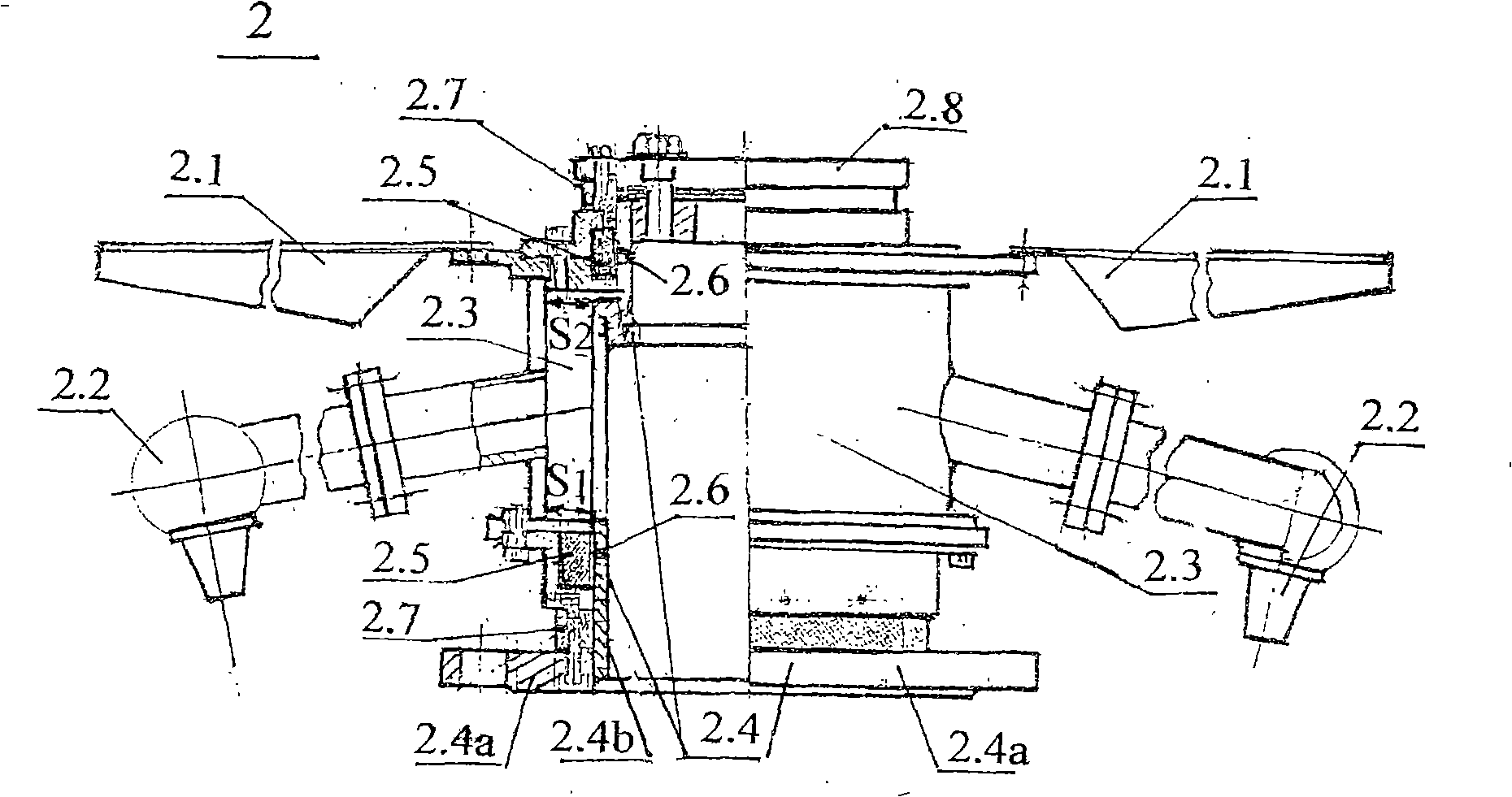

[0040] Example 1: see Figure 1 to Figure 5

[0041] See figure 1 , mixed-flow spray propulsion ventilation cooling tower, the overall structure and layout are described as follows (A) (B) (C) (D) (E):

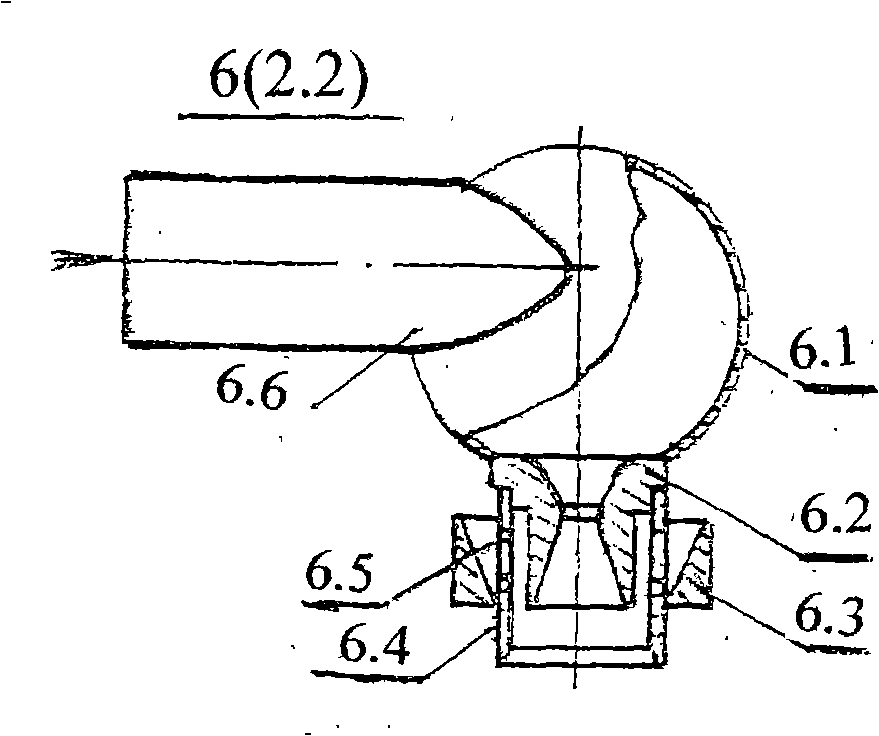

[0042] (A) In the tower body 17, the spray propulsion atomization device 2, the jet flow collecting tray 3 and three water pipes 5 and the screen air cylinder 16 fixed by its chassis are installed sequentially from top to bottom. On the outer periphery of the screen air duct 16, a water-spraying sieve plate 7 sealed between the water pipe 5 and the tower wall is installed under the water-draining sieve plate 7, and a layer of water-spraying screen that is sealed with the screen air duct 16 and the tower wall is arranged under the water-draining sieve plate 7. 8; the louver air outlet 10 is opened on the tower wall at the bottom of the water spraying screen 8 and the outer periphery of the screen air duct 16. The lower end of the water spraying screen 8 axially extends to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com