Micro-cavity gas-sensitive sensor based on simple root metallic oxide nanometer lines field effect tube

A technology of gas sensor and field effect transistor, which is applied in the field of microcavity gas sensor, can solve the problems of high working temperature and slow response speed, and achieve the effect of improving test sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below by way of examples.

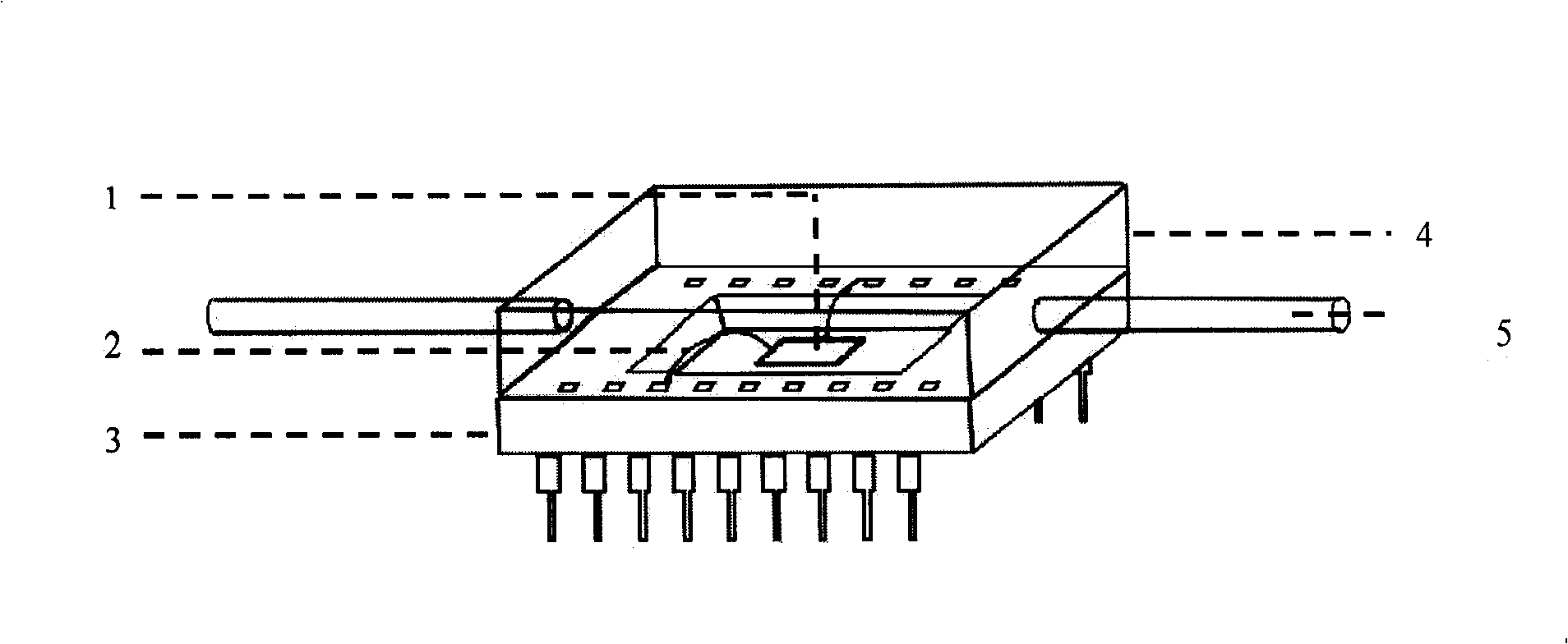

[0023] 1. Device preparation

[0024] The material of this embodiment uses a single ZnO nanowire as the gas-sensing material, and the oxide layer 7 of the base adopts SiO 2 , The preparation of the device is divided into two steps: the preparation of the gas sensor chip and the packaging of the gas sensor.

[0025] Preparation of gas sensor chip:

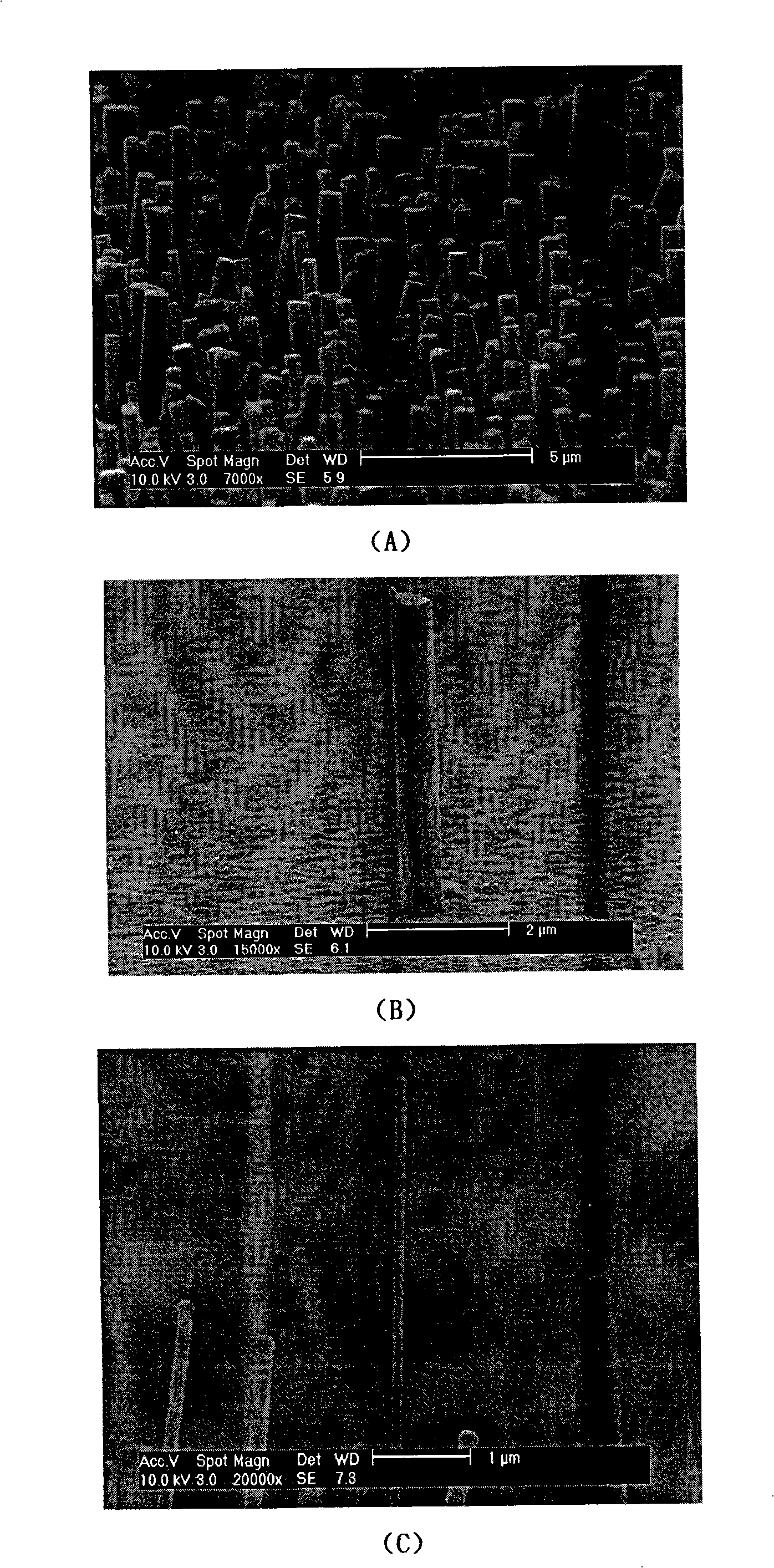

[0026] (1) ZnO nanowires 8 (such as figure 1 shown).

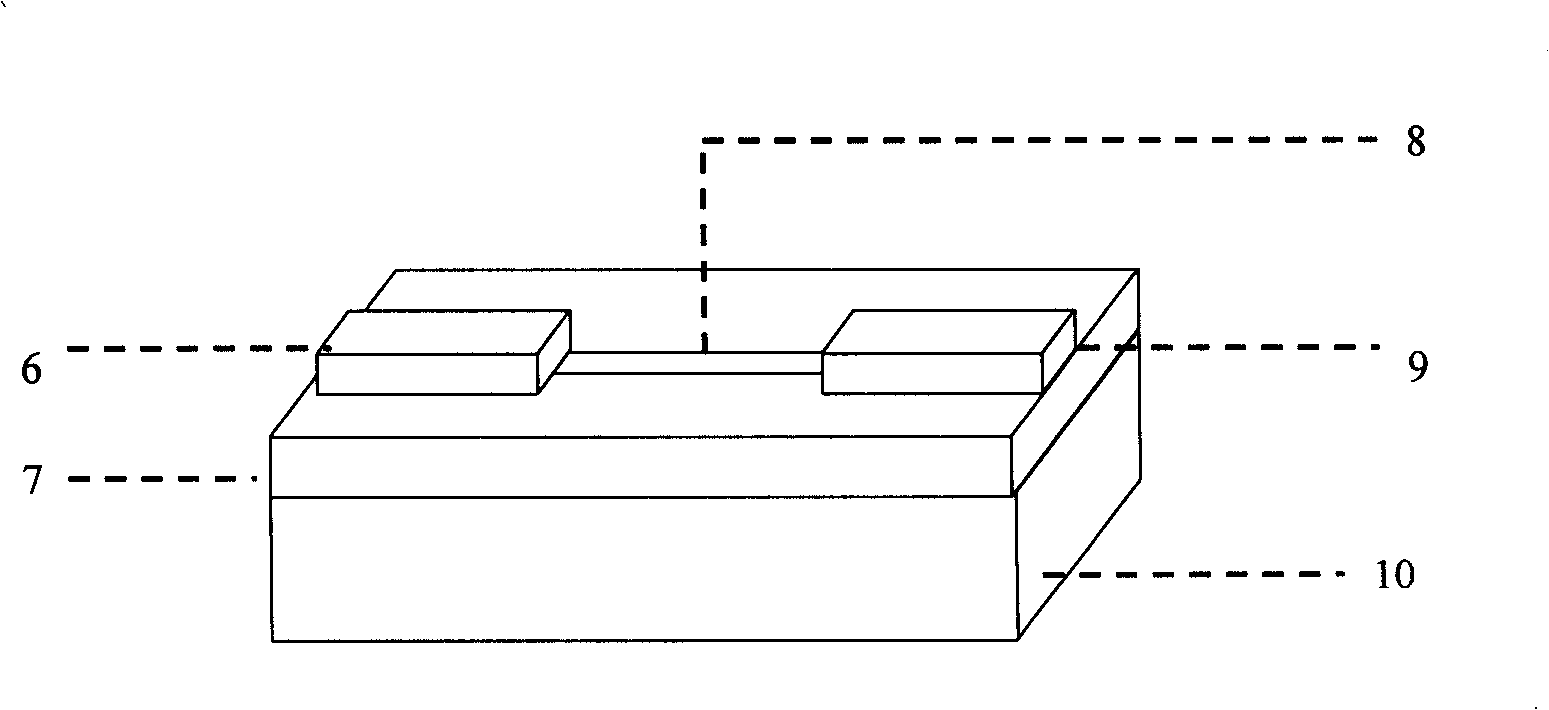

[0027] (2) A P+ silicon wafer is used as the substrate 10, and an oxide layer 7 with a thickness of 100-500 nanometers is prepared on the surface thereof.

[0028] (3) The prepared nanowires are dispersed with alcohol and sprinkled on the surface of the substrate.

[0029] (4) Spin-coat a photoresist of 1.5 microns to 3 microns on the substrate, and develop after exposure under the square matrix electrode template.

[0030] (5) Deposit a layer of Au / Ti or Au / Ni electrode with a thickness of 100-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com