Six freedom degree jiggle station

A technology of degree of freedom and micro-motion stage, which is applied in the direction of microlithography exposure equipment, large fixed members, metal processing machinery parts, etc., can solve the problem of increasing development cost, prolonging the development cycle, complex assembly and installation process of micro-motion stage drive device, etc. problems, to achieve the effect of short development cycle, simple structure and assembly and installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

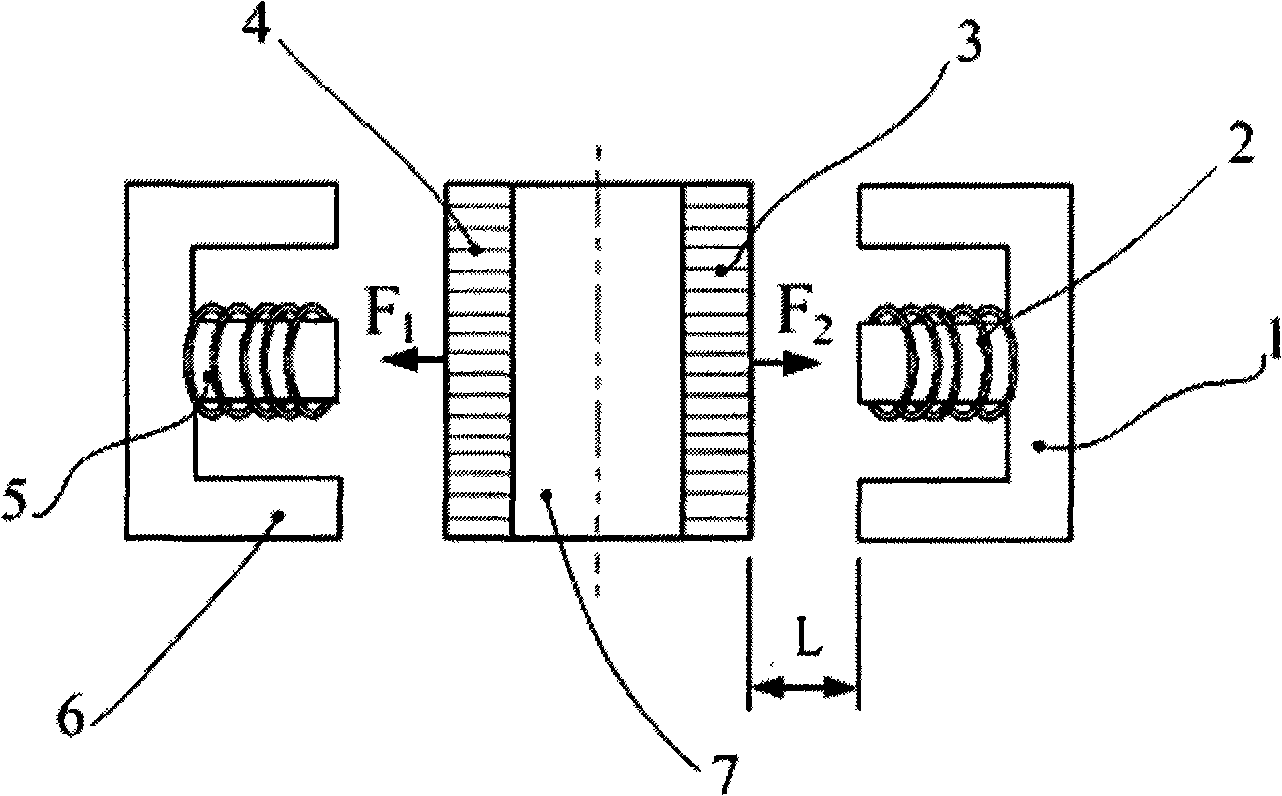

[0015] as attached figure 1 As shown, the present invention adopts the operating principle of the electromagnet, and two groups of electromagnets are placed side by side, and the electromagnet coil is fixedly placed as the stator of the micro-actuator, and the armature part is fixedly installed (mechanically connected or bonded) on the mover of the micro-drive device. superior. When the left and right electromagnet coils 2 and 5 are energized, the electromagnetic attraction acts on the micro-actuator mover 7 through the electromagnetic armatures 3 and 4 respectively, and the position of the mover at which the two electromagnet poles 1 and 6 are equal to the armature attraction is taken as the balance position. By controlling the magnitude of the coil current and fine-tuning the electromagnetic attraction force of the coil poles to the armature, the relative position of the mover 7 of the micro-actuator between the two poles 1 and 6 is controlled, and the functions of rapid pos...

Embodiment 1

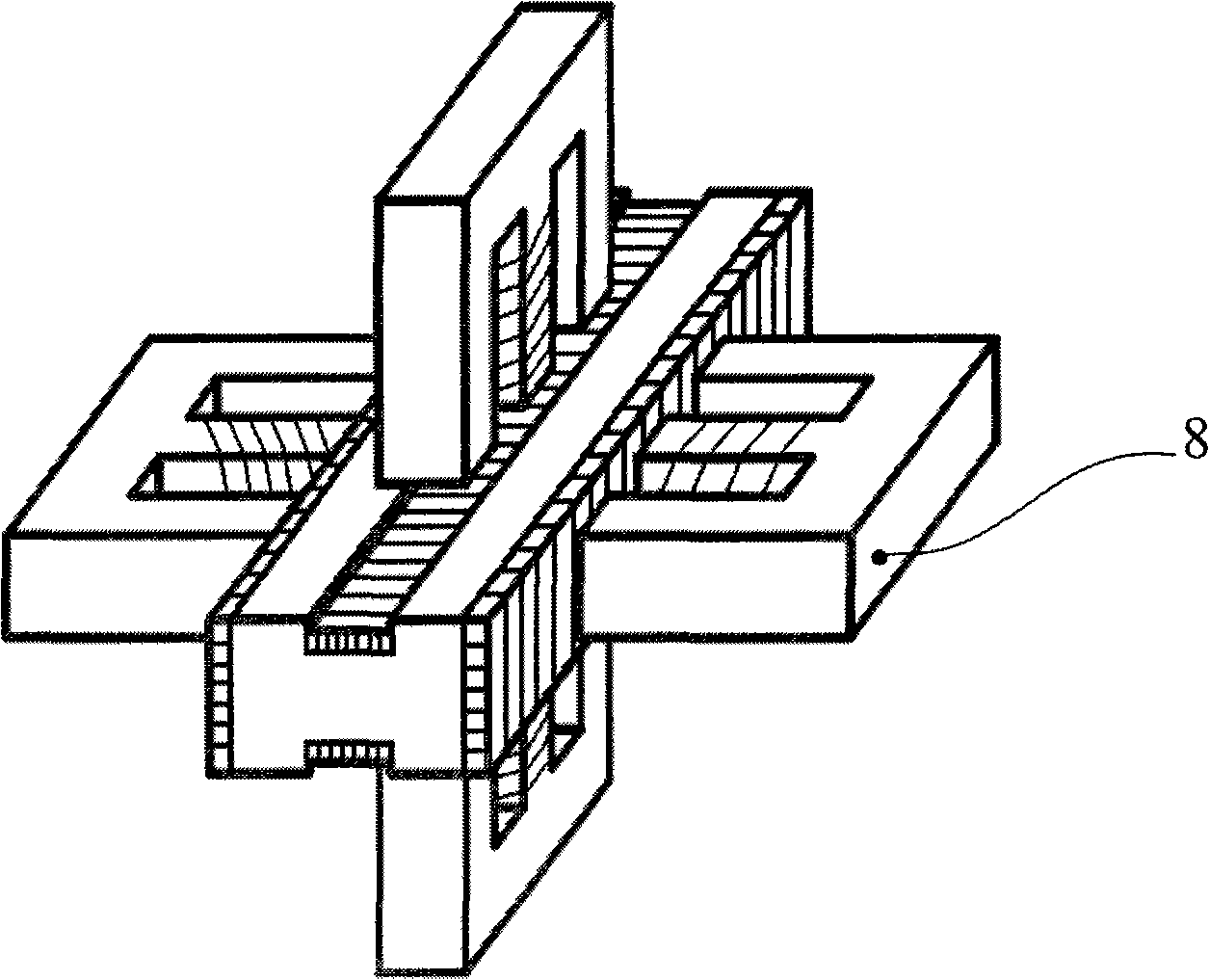

[0047] as attached Figure 4 As shown, the three groups have as figure 2 The micro-actuating device 8 with a special structure is arranged inside the micro-moving table in a circle of 120°, and the geometric center of the three groups of driving devices coincides with the center of gravity of the micro-moving table. The 4 electromagnet coils of the micro-drive device 8 are installed on the large-stroke drive base, and the mover is directly connected with the micro-motion bearing platform. In this way, the interference of the heat generated by the electromagnet coil on the micro-motion stage can be minimized. The position control of the mover can use a capacitive sensor or a nanoscale position sensor such as an LVDT as a measurement sensor.

Embodiment 2

[0049] as attached Figure 5 As shown, it is also possible to use four sets with figure 2 The micro-actuating devices 8 of special structure are vertically arranged inside the micro-moving table, so that the geometric centers of the four groups of the driving devices coincide with the center of gravity of the micro-moving table. This layout method has a redundant degree of freedom in the vertical and horizontal directions, which brings difficulty and complexity to the control, but this method has the advantages of large driving force and smooth movement.

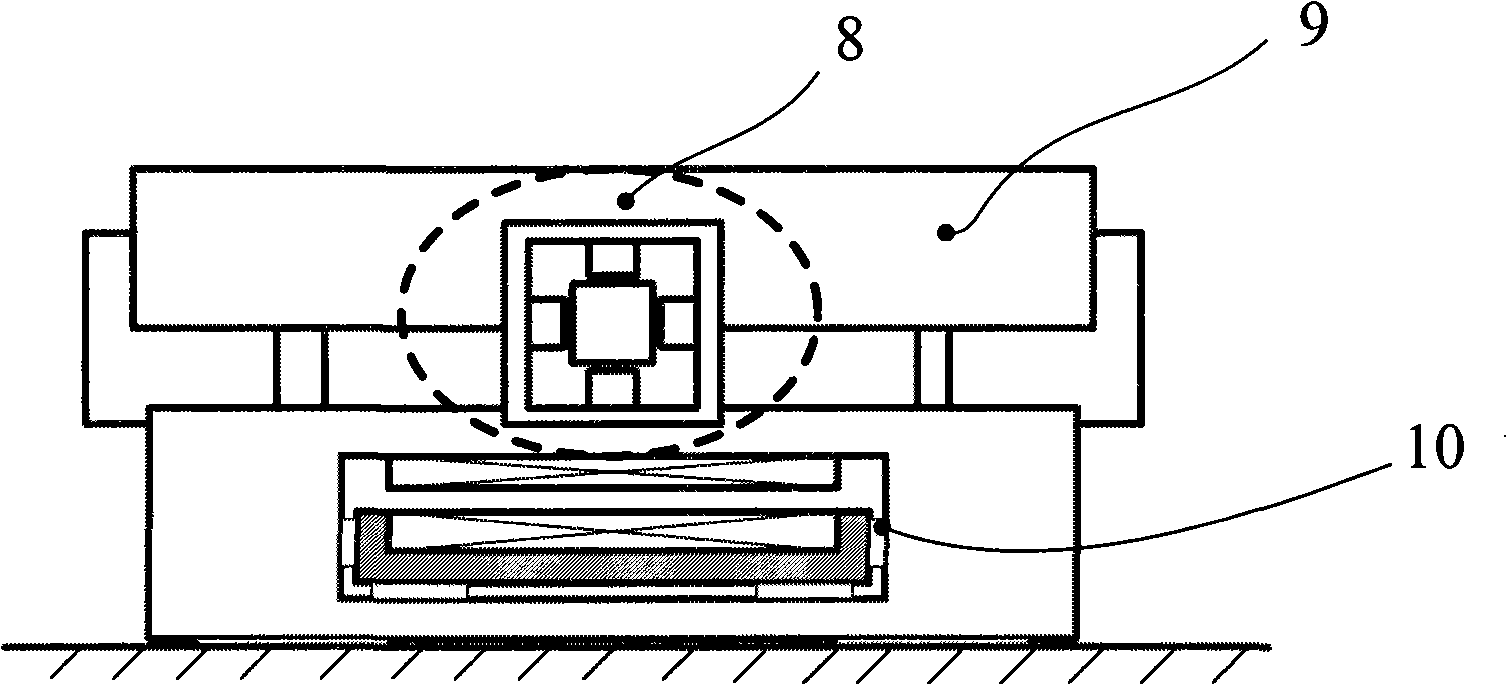

[0050] Such as image 3 As shown, the six-degree-of-freedom micro-motion platform of the present invention also includes a micro-motion bearing platform installation base 9, which is connected to a fixed micro-motion bearing platform; it is also connected with a long-stroke driving device 10, which is used for long-stroke low-precision movement, Realize preliminary rough positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com