Semiconductor device manufacturing method and display device

一种制造方法、半导体的技术,应用在半导体/固态器件制造、半导体器件、照明装置等方向,能够解决增加扫描时间、降低产率、增加制造成本等问题,达到高显示质量、提高产率、抑制不利影响的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

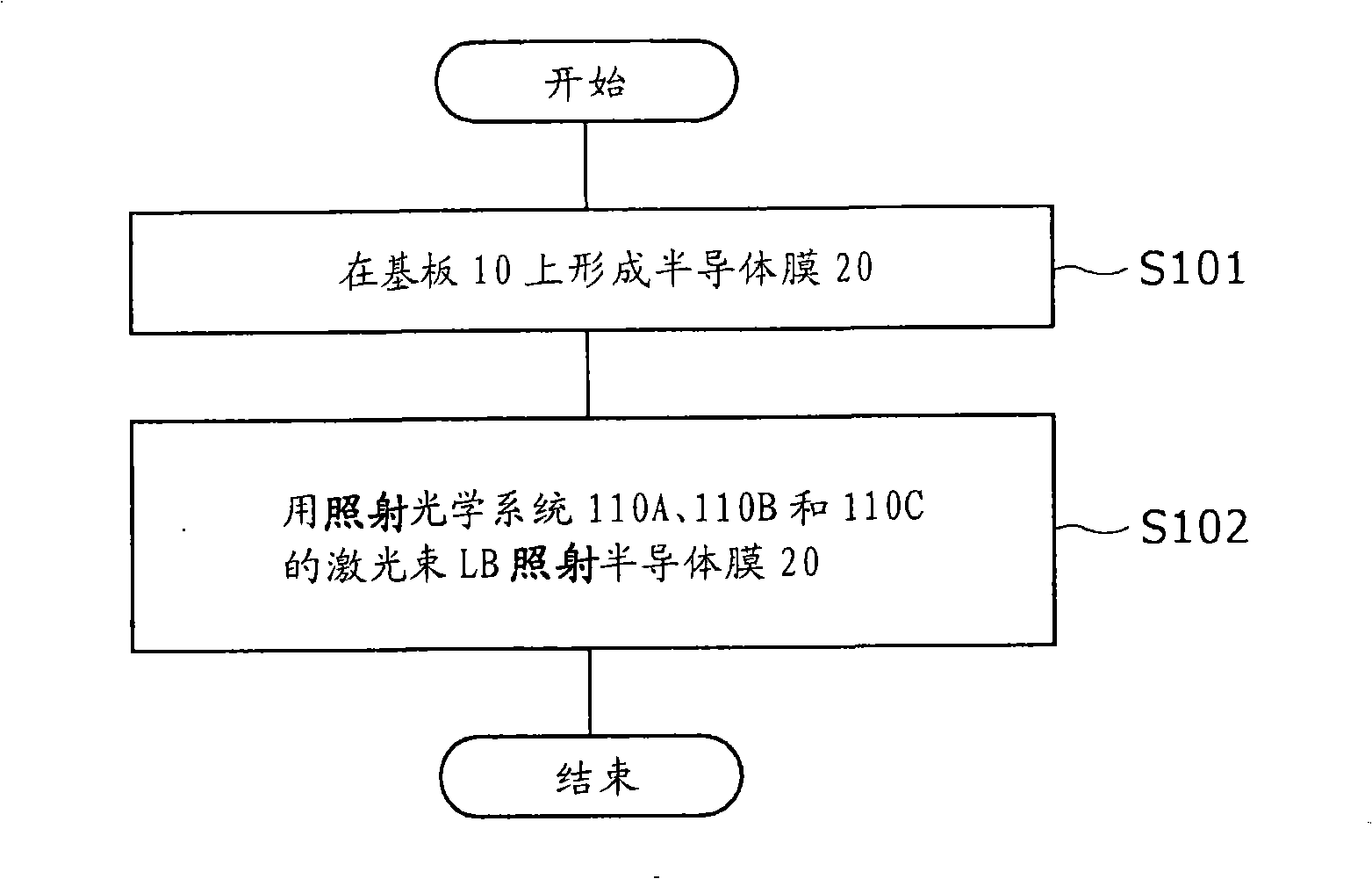

[0026] Hereinafter, a method of manufacturing a semiconductor device and a display apparatus according to embodiments of the present invention will be described with reference to the accompanying drawings.

[0027] [General configuration of display device]

[0028] First, the general configuration of a display device will be described by taking an organic EL display device as an example.

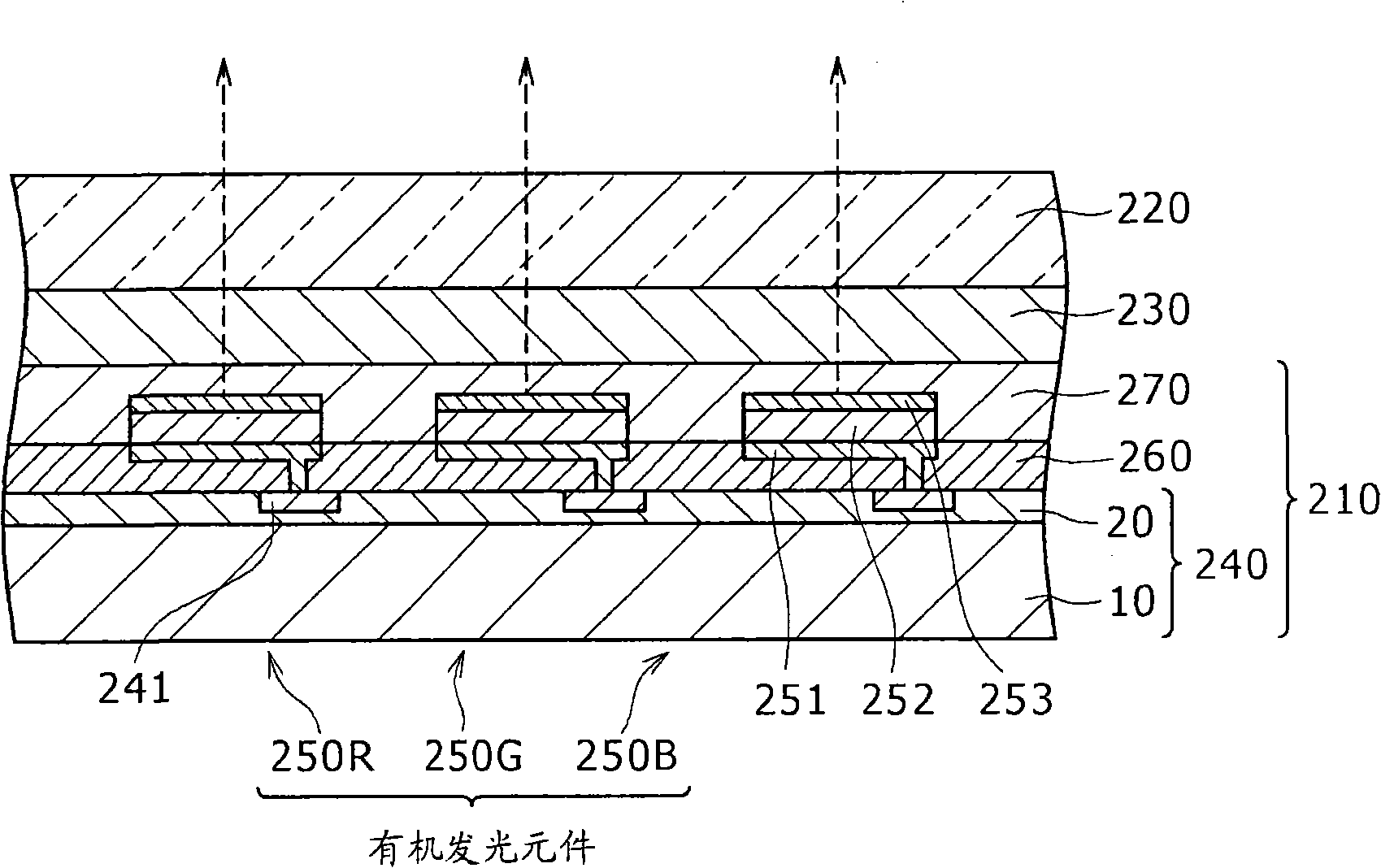

[0029] figure 1 is an auxiliary schematic diagram illustrating an example of a general configuration of an organic EL display device.

[0030] figure 1 The shown display device is, for example, an active or passive type very thin organic EL display device driven by TFTs. The display device is formed by disposing the driving panel 210 and the sealing panel 220 so that the driving panel 210 and the sealing panel 220 face each other, and providing the adhesive layer 230 formed of thermosetting resin or ultraviolet curable resin between the driving panel 210 and the sealing panel 220 to la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com