Method for preparing highly-acidproof mordenite molecular sieve membrane

A technology of mordenite and molecular sieve, which is applied in the direction of mordenite crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., to achieve the effects of simple synthesis device, good separation performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

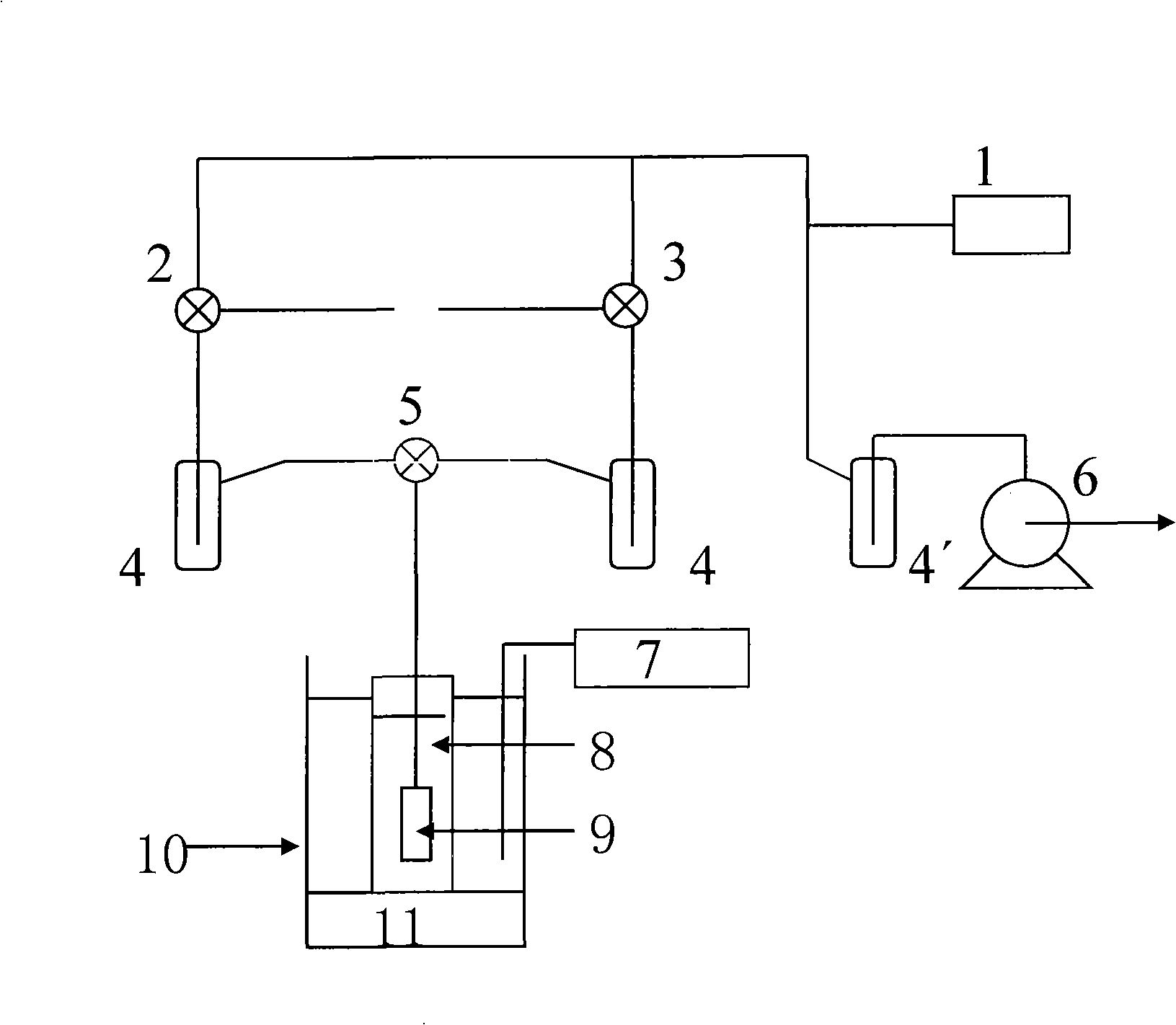

Method used

Image

Examples

Embodiment 1

[0042] Add a certain amount of sodium aluminate solid into a beaker filled with a certain amount of water, and stir until it dissolves to form solution A. Take another certain amount of NaOH solid and dissolve it in a certain amount of water, stir until dissolved, then pour it into a beaker containing a certain amount of white carbon black solid, stir, add the remaining water, and stir for 20 minutes to form solution B. Then transfer solution A to a plastic bottle, inject solution B into the plastic bottle with stirring, and stir for 2 hours. Then the reaction mixture was transferred into a mullite reactor, and crystallized at a constant temperature of 170°C for 24h. Cool, filter with suction, wash, and dry the recovered product at 100°C for 12 hours. A solid product was obtained.

[0043] The reaction mixture molar ratio is:

[0044] SiO 2 / Al 2 o 3 =30,Na 2 O / SiO 2 =0.2,H 2 O / Na 2 O=130

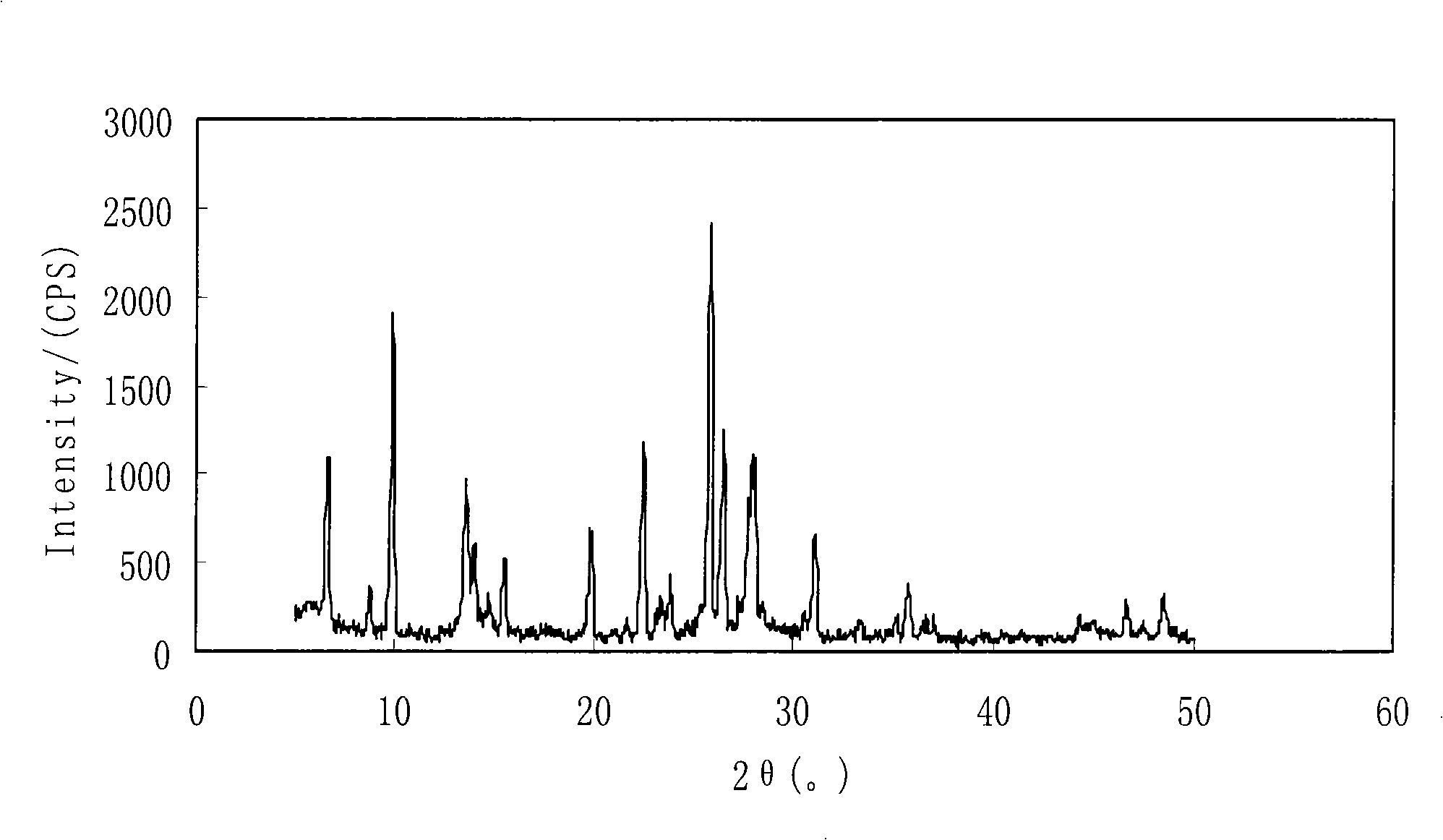

[0045] The solid powder product is analyzed by X-diffraction, and the result...

Embodiment 2

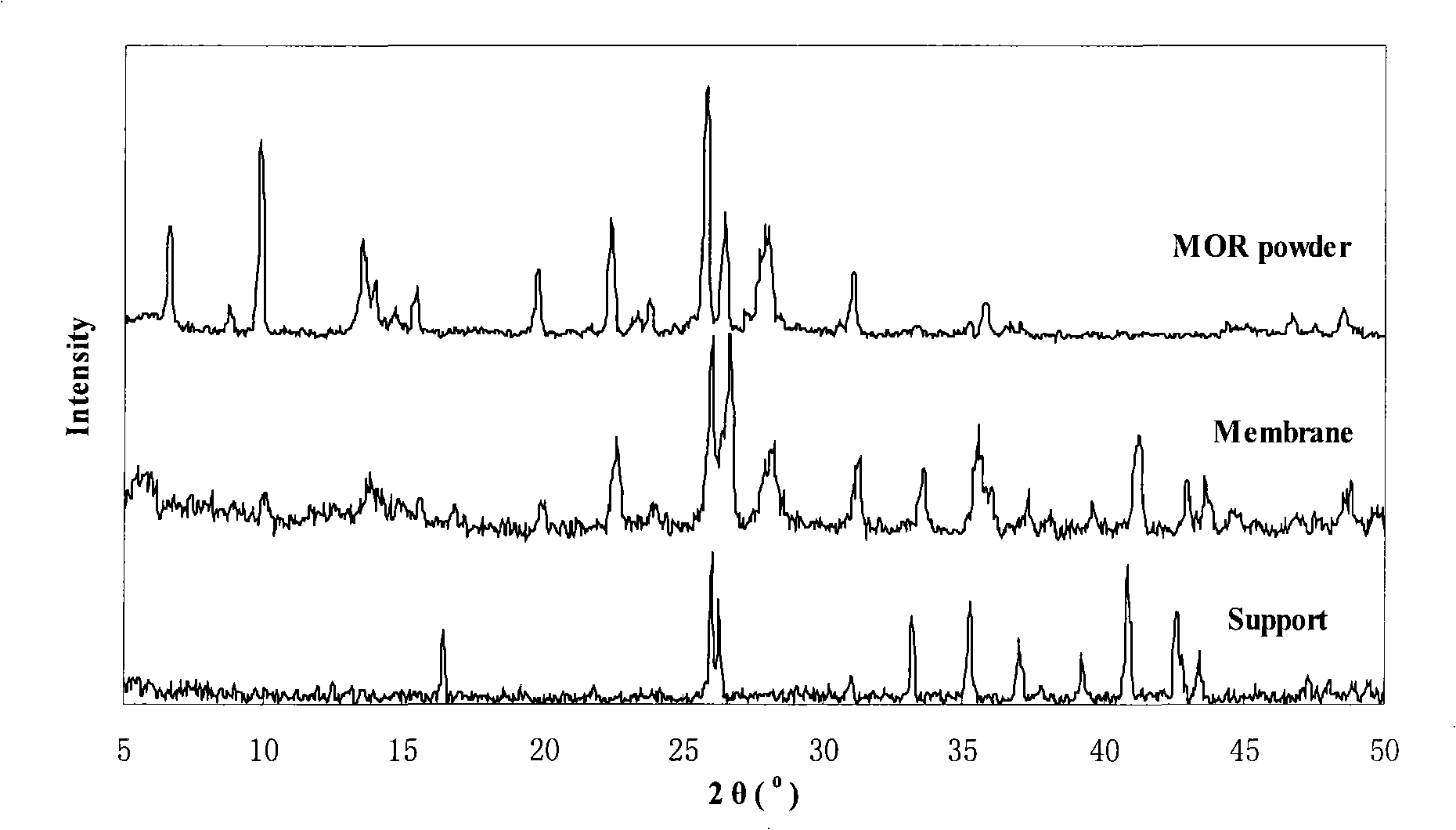

[0047] The support body adopts tubular mullite produced by Japan Nikkato Co., Ltd. (the composition of mullite is 67wt.%Al 2 o 3 and 33wt.% SiO 2 ). The support body is polished with 800-mesh sandpaper and ultrasonically cleaned, and then dried after ultrasonic cleaning and other pretreatments. A thin layer of MOR molecular sieve powder is coated on the surface of the support body, and the loading density of the seed crystal is 0.5-2mg / cm 2 , and the pre-seeded support was air-dried at 20°C for later use.

[0048] Silica sol (SiO 2 ·nH 2 O), aluminum isopropoxide (Al(OC 3 h 7 ) 3 ) is silicon, aluminum source raw material, and sodium hydroxide is as alkali raw material, and preparation raw material liquid is SiO with molar ratio 2 / Al 2 o 3 =25,Na 2 O / SiO 2 =0.33,H 2 O / Na 2 O=150 mixed, vigorously stirred for 5h to form a stable sol. The configured sol is poured into a stainless steel reaction kettle, and the support body pre-coated with MOR molecular sieve seed...

Embodiment 3

[0058] Synthesis ratio and preparation steps are the same as in Example 2. The difference is that the crystallization time is extended to 25h. The pervaporation performance of the synthesized membrane was investigated in a water / ethanol (10 / 90wt.%) system at 75°C after cleaning. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Load density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com