Extension method of material for low forward voltage drop Schottky diode

A technology of Schottky diode and forward voltage drop, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high forward voltage drop, reduction of effective thickness of epitaxy, poor repeatability and reproducibility, etc. achieve low forward voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

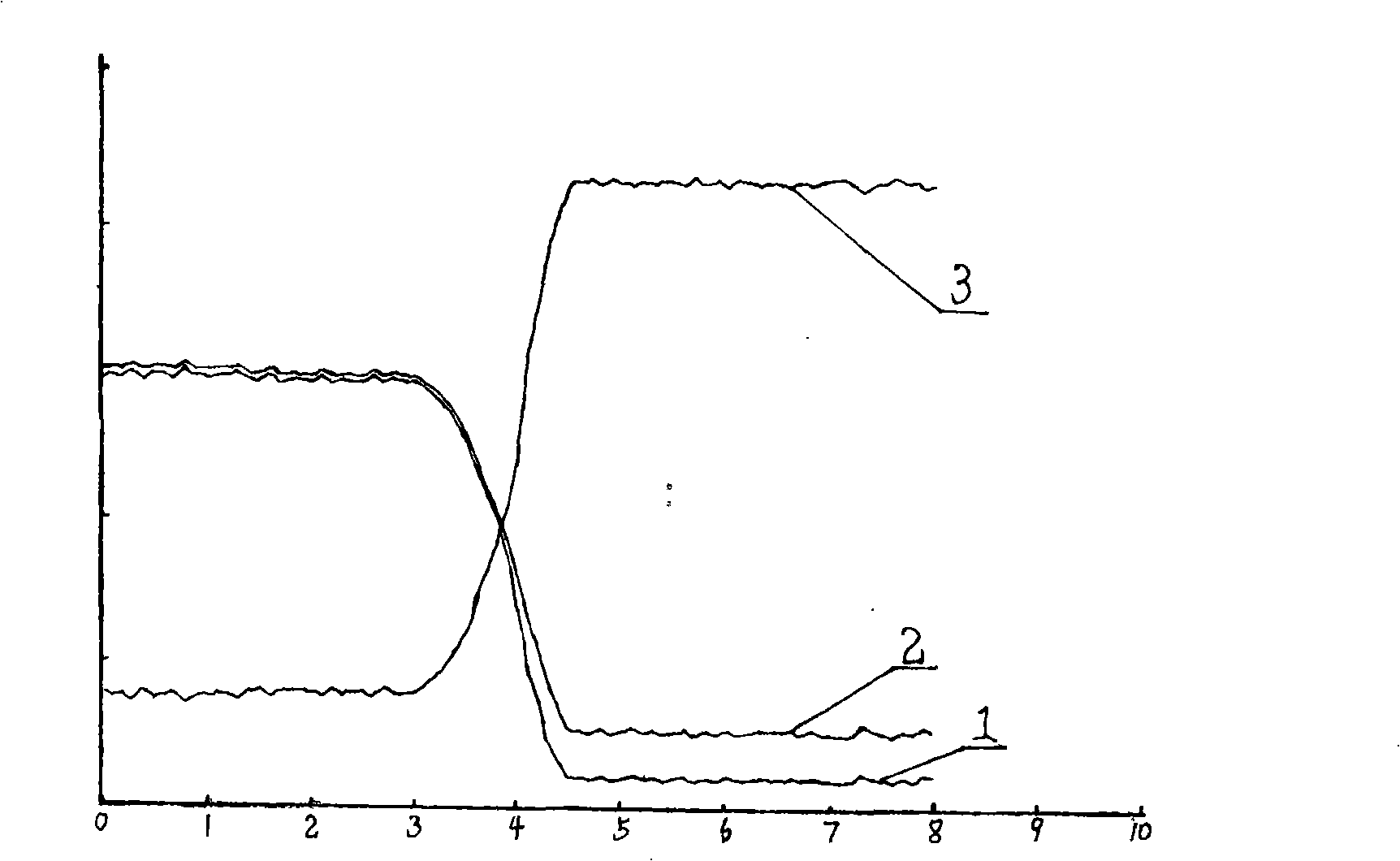

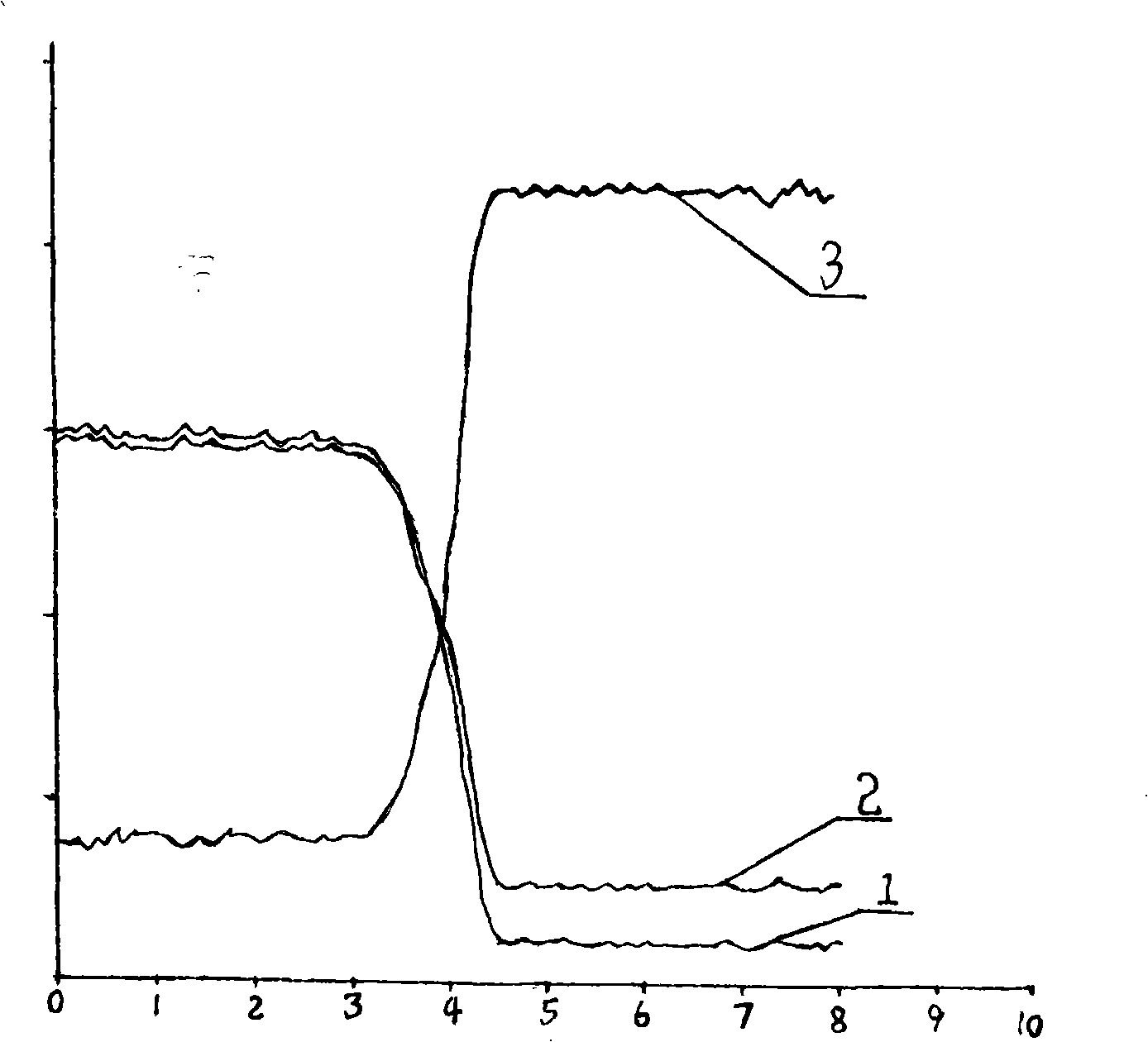

[0030] Below in conjunction with experimental result the present invention is described in further detail:

[0031] 1. Put the substrate into the reaction chamber, first use nitrogen gas for 3 minutes, then turn off the nitrogen gas, and then use hydrogen gas (the hydrogen valve is opened to the maximum) to drive nitrogen gas for 4 minutes;

[0032] 2. Reduce the hydrogen flow rate to 60-150 liters per minute, such as the usual 100 liters per minute, and raise the temperature of the reaction chamber from room temperature to 650 degrees in 5 minutes, and from 650 degrees to 900 degrees in 10 minutes. It takes 8 minutes to rise from 900 degrees to 1150 degrees, and it takes 6 minutes to raise the temperature from 1150 degrees to 1190 degrees, such as a typical 1160 degrees. During the process of rising from 1150 degrees to 1190 degrees, increase the hydrogen flow to 180-220 L / min, such as the usual 200 liters / min, while feeding HCl to get rid of gas;

[0033] 3. After heating u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com