Decorative protective coating and synthetic method thereof

A technology of protective coating and synthesis method, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of high difficulty in consistency, large color difference, complicated process, etc., and achieve simple control, color difference Small, reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: vapor deposition black hard decorative protective coating silicon-carbon-nitrogen

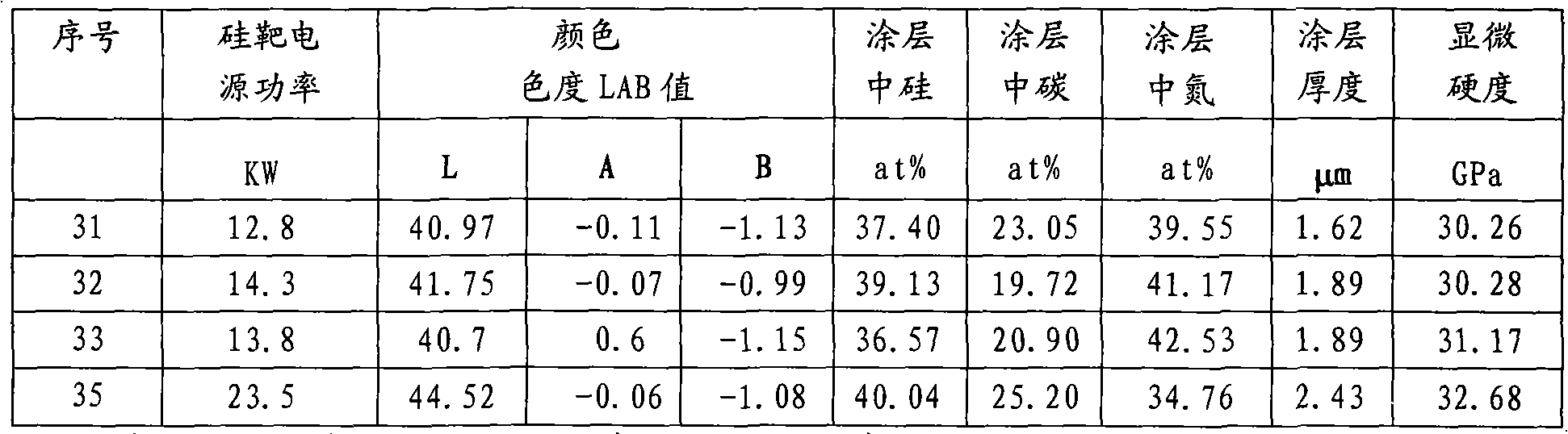

[0014] The chemical composition, color and performance of the silicon-carbon-nitrogen coating can be effectively controlled by the power of the sputtering power supply and the flow rate of the reactive gas. Some of the test results are shown in Table 1.

[0015] Table 1 Silicon-carbon-nitrogen coating chemical composition (at%) and performance test results*

[0016]

[0017] * Note: When using a microhardness tester, load 0.02kg, hold time for 30s, and test the average hardness of different parts 5 times.

[0018] In the SP0811SI vapor deposition equipment, two rectangular silicon targets are used, and the turret is still; the reaction gas is nitrogen and CH4; the deposition temperature is about 250°C; by adjusting the silicon target intermediate frequency magnetron sputtering power (5-25kW ), and adjust the reaction gas (N 2 and CH 4 or C 2 h 2 etc.) traffic (e.g. ...

Embodiment 2

[0026] Embodiment 2: Vapor deposition black hard protective coating titanium-silicon-carbon-nitrogen

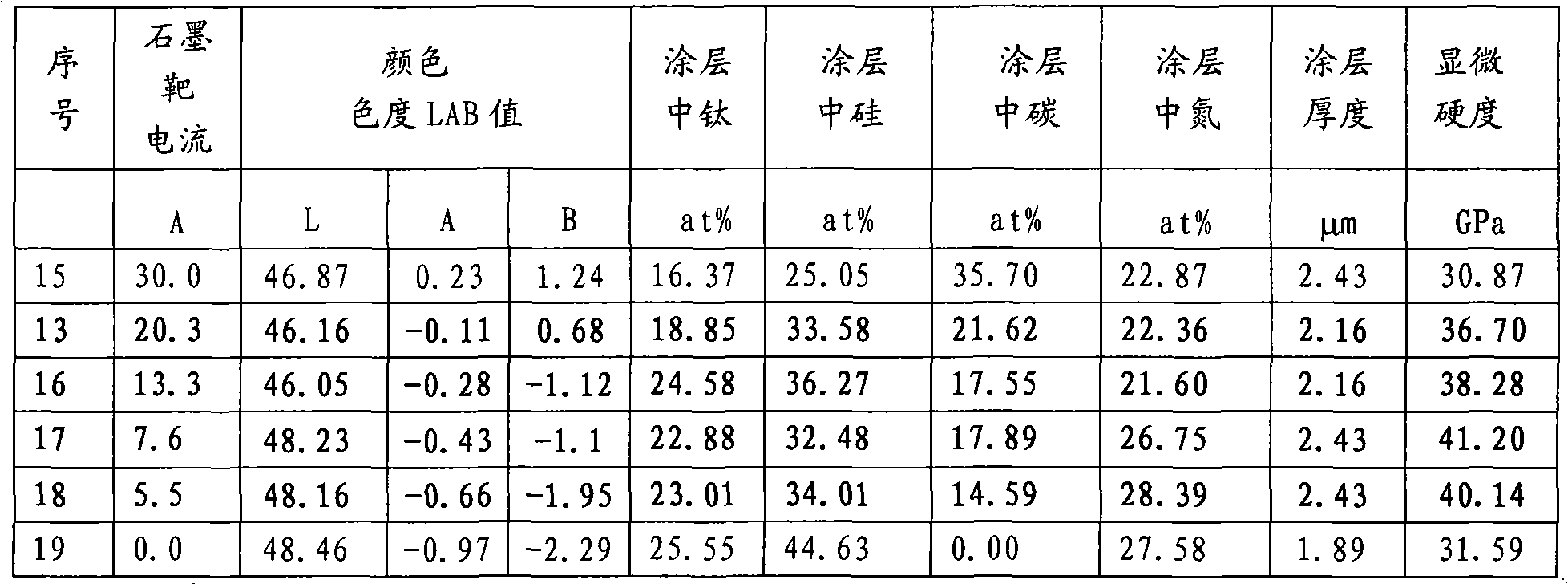

[0027] The chemical composition, color and performance of the titanium-silicon-carbon-nitrogen coating can be effectively controlled by the power of the sputtering power supply and the flow rate of the reactive gas. Some test results are shown in Table 2.

[0028] Table 2 Titanium-silicon-carbon-nitrogen coating chemical composition (at%) and performance test results**

[0029]

[0030] **Note: The serial numbers in this table are 13, 16, 17, and 18, which are optimized experiments; when testing with MH-5 microhardness tester, load 0.02kg, hold time for 5s, and test the average hardness of different parts for 5 times , 6 heats are randomly sampled, three different points are taken for each sample, the hardness of each point is measured three times, and the average value is taken as the hardness value of the point, and the average value of the hardness values of the three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com