Solid electrolytic capacitor

A solid electrolysis, solid electrolyte layer technology, applied in solid electrolytic capacitors, capacitor parts, capacitor electrolytes/absorbents, etc., can solve problems such as low performance, and achieve the effect of excellent ESR performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

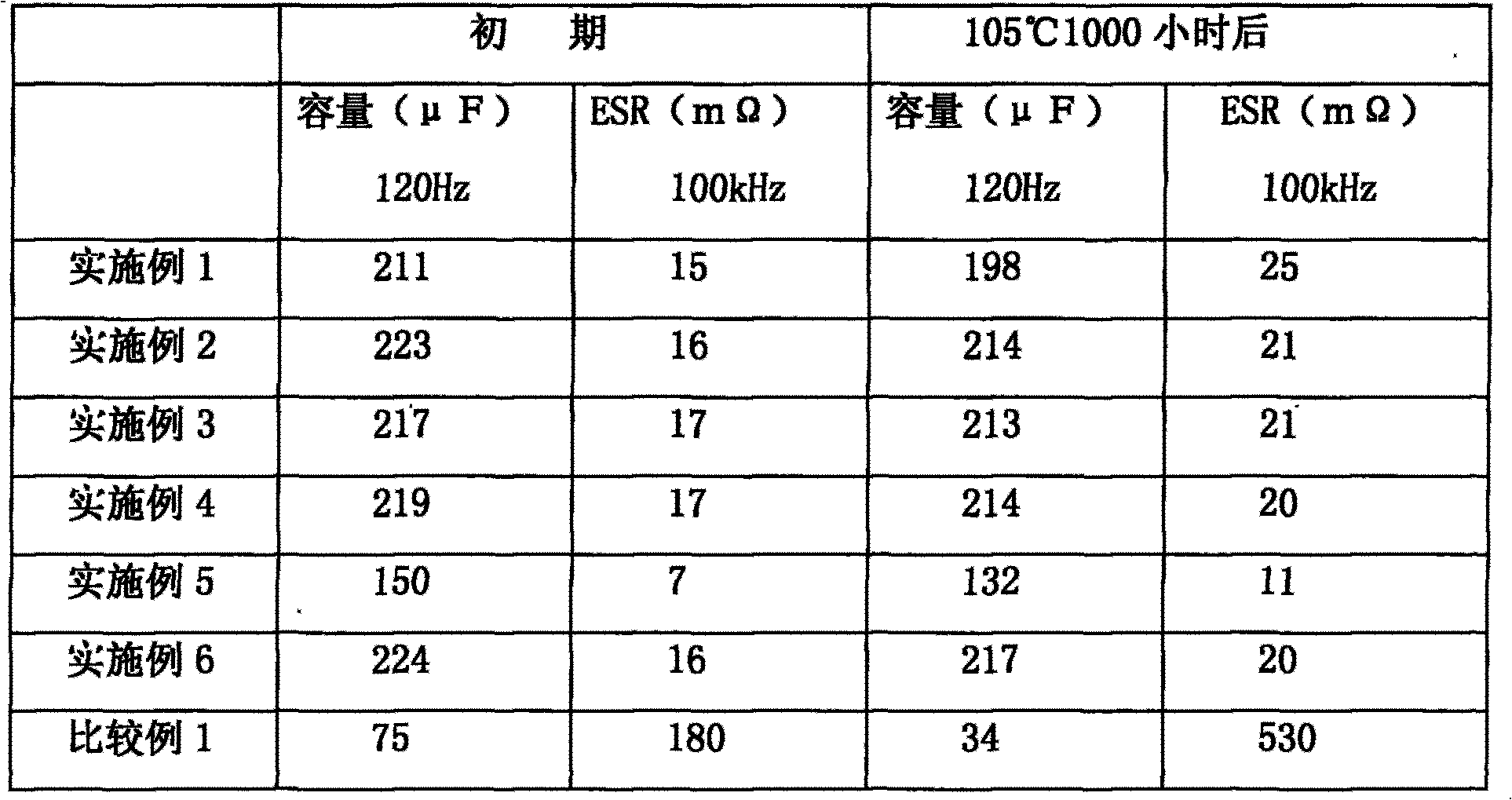

Examples

Embodiment 1

[0088] (Synthesis of polystyrenesulfonic acid-poly(3,4ethylenedioxy)thiophene)

[0089] With 5g of 3,4-ethylenedioxythiophene, 500g of 3wt% polystyrenesulfonic acid aqueous solution, 10g of 50wt% sulfophthalic acid aqueous solution and 9g of sodium persulfate, 1g of iron sulfate dissolved in 500ml of water , stirred for 18 hours.

[0090] After treatment with aqueous ammonia, ion exchange resin was used to remove residual ions in the solution to obtain dark blue 1.6 wt% polystyrene sulfonate ammonium-poly(3,4-ethylenedioxy)thiophene aqueous solution.

[0091] 10 g of the obtained 1.6 wt % polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene aqueous solution and 0.8 g of triethylene glycol were mixed and stirred to obtain a dark blue solid electrolyte solution.

[0092] (Manufacturing of solid electrolytic capacitors)

[0093] After the solid electrolyte solution is impregnated into the semi-finished element of the wound capacitor by vacuum decompression method, it is dr...

Embodiment 2

[0095] 10 g of 1.6 wt % polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene aqueous solution obtained in Example 1 and 0.8 g of polyglycol 1000 were mixed and stirred to obtain a dark blue solid electrolyte solution.

[0096] After impregnating the solid electrolyte solution into the semi-finished element of the winding capacitor by vacuum decompression method, dry it in an oven at 120°C, then impregnate 10wt% ammonium adipate aqueous solution, and dry it in an oven at 120°C. After the case and the rubber cover seal the element containing the solid electrolyte, a solid electrolytic capacitor is obtained. The same method as in Example 1 was evaluated, and the results are shown in Table 1.

Embodiment 3

[0098] 10g of 1.6wt% polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene aqueous solution obtained in Example 1, 0.2g of xylitol and 0.8g of polyglycol 1000 were mixed and stirred to obtain dark blue solid electrolyte solution. In the same manner as in Example 2, a solid electrolytic capacitor was obtained, and the evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com