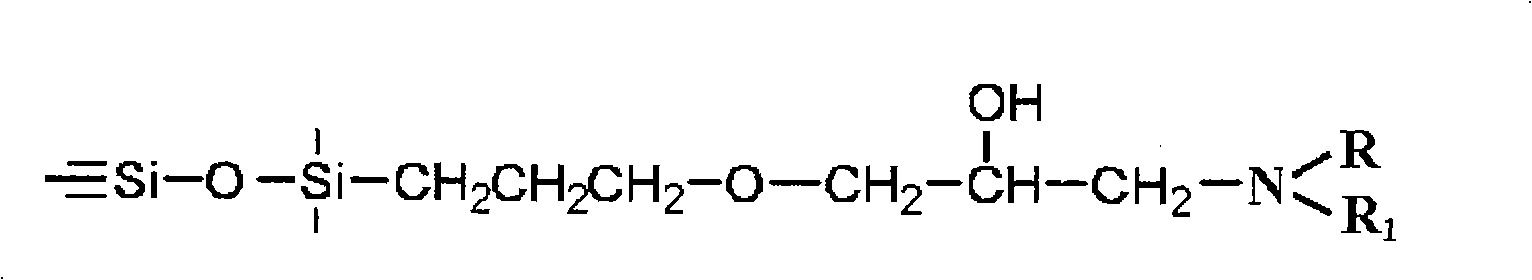

Alkylamine silica gel capillary monolithic column and preparation method and use thereof

A capillary monolithic column, alkylamine technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problem of few silica-based monolithic columns, and achieve silica-based matrix network permeability and high mechanical strength, Increased hydrophilicity and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

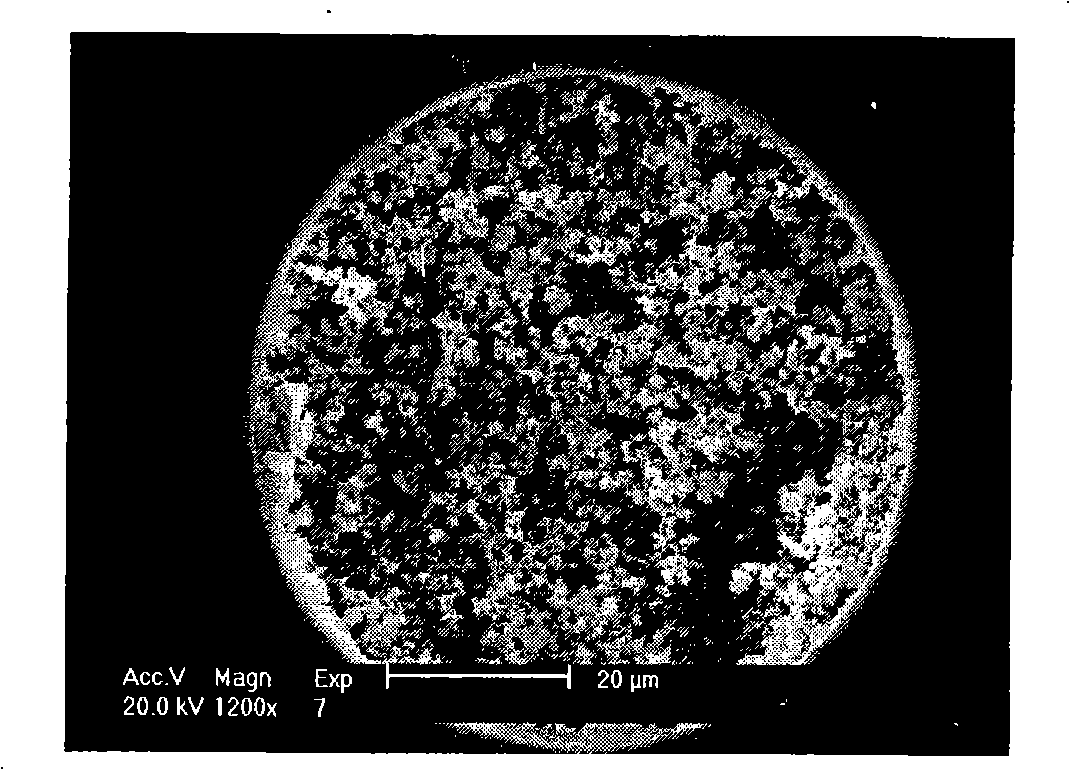

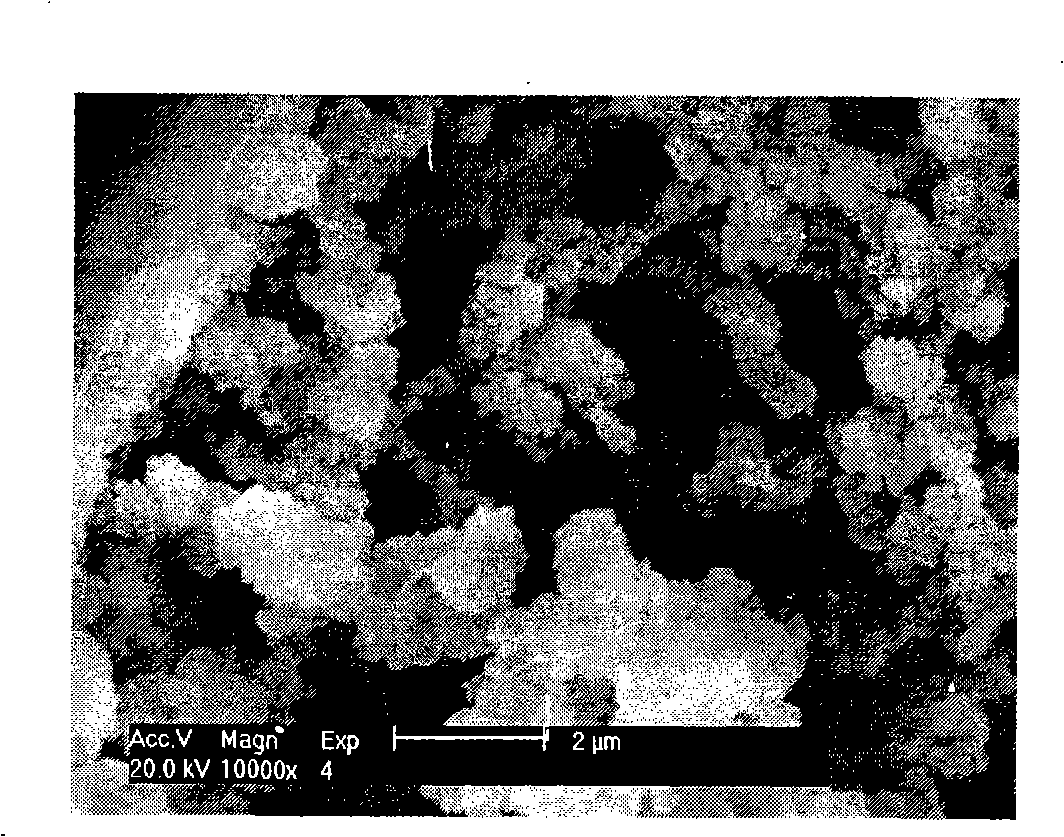

[0041] (1) Preparation of silica gel monolithic column: Take a quartz capillary with an inner diameter of 75 μm and an outer diameter of 365 μm, soak it with 1 mol / L NaOH solution overnight, rinse with secondary water, hydrochloric acid, secondary water, acetone, and anhydrous ether for 1 hour, Then pass N 2 Dry at 180°C for 3 hours, and seal both ends for later use. 0.22g of polyethylene glycol (Mr=10000), 0.225g of urea were dissolved in 2.5mL of 0.01mol / L acetic acid solution, wherein 1mL of tetramethoxysilane and methyltrimethoxysilane (9 / 1, v / v), stir vigorously in an ice bath until the solution becomes a transparent and uniform sol, inject it into the pretreated capillary, seal both ends with silicone rubber, put it in a constant temperature water bath at 40°C for 25h, take it out, and store it at 120°C Under heat treatment for 3h to obtain proper specific surface and pore structure. Cut off the seal, rinse out unreacted substances with water, rinse with water and abs...

Embodiment 2

[0047] Using 2.5 g of n-decylamine instead of n-tetradecylamine, the procedure in Example 1 was followed to obtain a n-decylamine capillary monolithic column.

Embodiment 3

[0049] Using the alkylamine silica gel capillary monolithic column prepared in Example 1, the cut-off total length is 30cm, and the effective length is 20cm. , v / v) buffer solution is the mobile phase, under the conditions of applied voltage -15kV and detection wavelength 214nm, the homologues of benzene are separated, and the corresponding peaks are 1. benzene, 2. toluene, 3. ethylbenzene, 4. propylene Benzene, 5. Butylbenzene, 6. Pentylbenzene, 7. Hexylbenzene. Its spectrum is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com