Device and process for preparing rare-earth compound uniform micro powder

A rare earth compound, uniform technology, applied in the direction of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as no occurrence, and achieve the effect of simple process, narrow particle size distribution range, and less agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

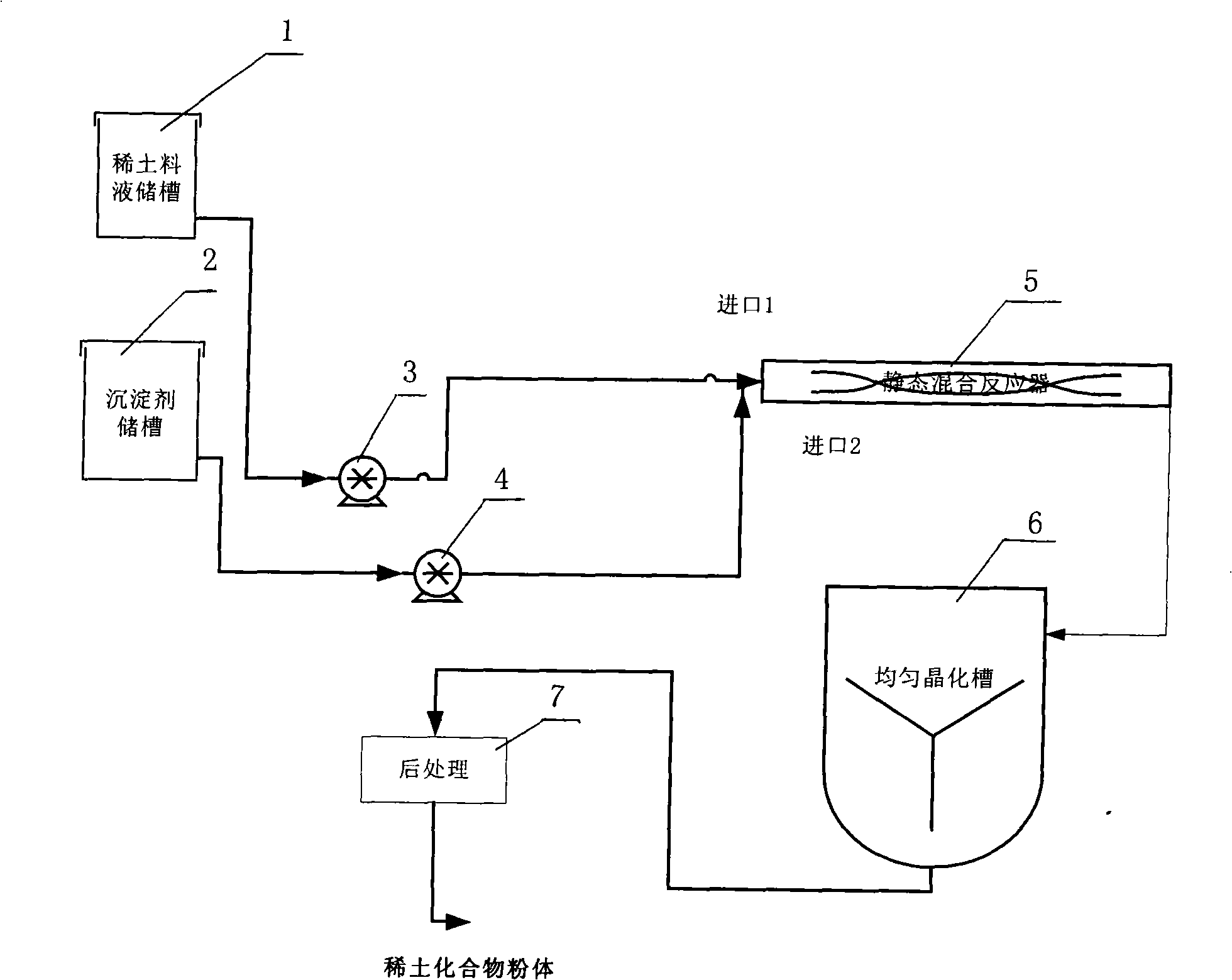

Image

Examples

Embodiment 1

[0027] At room temperature, prepare 50 L of rare earth chloride solution with a concentration of 0.5 mol / L and 50 L of ammonium bicarbonate solution with a concentration of 1.5 mol / L, put them into the rare earth feed liquid storage tank and precipitant storage tank, start the metering pump, 1 and 2 are poured into the static compound reactor at the same time, the flow rate of the mixed liquid in the reactor is 1.5m / s, and the sediment-containing slurry generated from the reactor directly enters the uniform crystallization tank with stirring, and after heating and stirring for 2 hours , the slurry is filtered, washed, and directly roasted to obtain the rare earth oxide powder. The particle size distribution is shown in Table 1.

Embodiment 2

[0029] At room temperature, prepare 50L each of 0.5mol / L rare earth chloride solution and 1.5mol / L sodium carbonate solution, put them into the rare earth feed liquid storage tank and the precipitant storage tank, start the metering pump at the same time, pass through the feed port 1 and 2 are poured into the static compound reactor at the same time. The flow rate of the mixed liquid in the reactor is 0.6m / s. The slurry generated from the reactor directly enters the uniform crystallization tank with stirring, and is heated and stirred for 2 hours. The slurry Filtration, washing, direct roasting to obtain rare earth oxide powder. The particle size distribution is shown in Table 1.

Embodiment 3

[0031] At room temperature, prepare 50 L of rare earth chloride solution with a concentration of 0.5 mol / L and sodium bicarbonate solution with a concentration of 1.5 mol / L, put them into the rare earth feed liquid storage tank and the precipitant storage tank, start the metering pump at the same time, and pass the feed Ports 1 and 2 are poured into the static compound reactor at the same time. The flow rate of the mixed liquid in the reactor is 1m / s. The sediment-containing slurry generated from the reactor directly enters the uniform crystallization tank with stirring, and is heated and stirred for 3h. The slurry is filtered, washed, dried and calcined at low temperature to obtain rare earth carbonate powder. The particle size distribution is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com