Plate type electro-deionization device

An electric desalination, plate-type technology, applied in the direction of magnetic field/electric field water/sewage treatment, etc., can solve the problems of low water utilization rate and high cost of electric desalination, reduce water consumption, improve water quality, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

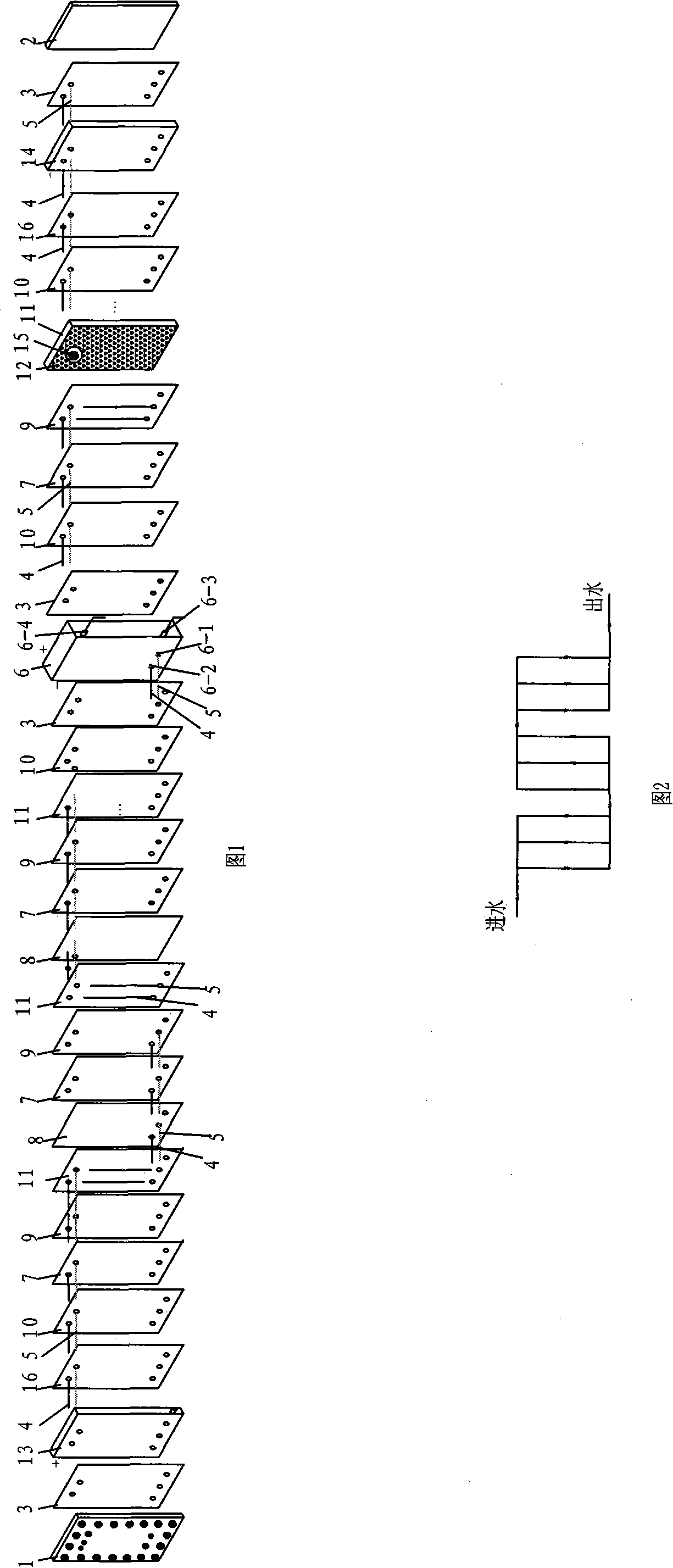

[0021] As shown in Figures 1 to 2, a plate-type electric desalter includes splints arranged at both ends, an electrode frame is arranged on the inner side of the splint 1, an insulating plate 3 is arranged between the splint 1 and the electrode frame, and the splint at the front end An anode is fixed on the inner electrode frame 13, and a cathode is fixed on the inner electrode frame 14 of the splint 2 at the rear end. Concentrated water inlet 1-1 and fresh water inlet 1-2 are provided on the electrode frame 13 inside the splint 1 at the front end, and a concentrated water outlet 2-1 and a fresh water outlet are provided on the electrode frame 14 inside the splint 2 at the rear end. 2-2 and polar water outlet 2-3. Between the electrode frame 13 and the electrode frame 14 of the two splints, an anion membrane 9 and an anode membrane 10 are arranged, and an anion membrane 9 and an anode membrane 10 form a pair of anion and cation exchange membrane pairs, and the electrode frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com