Composite titan-based grease and method for preparing same

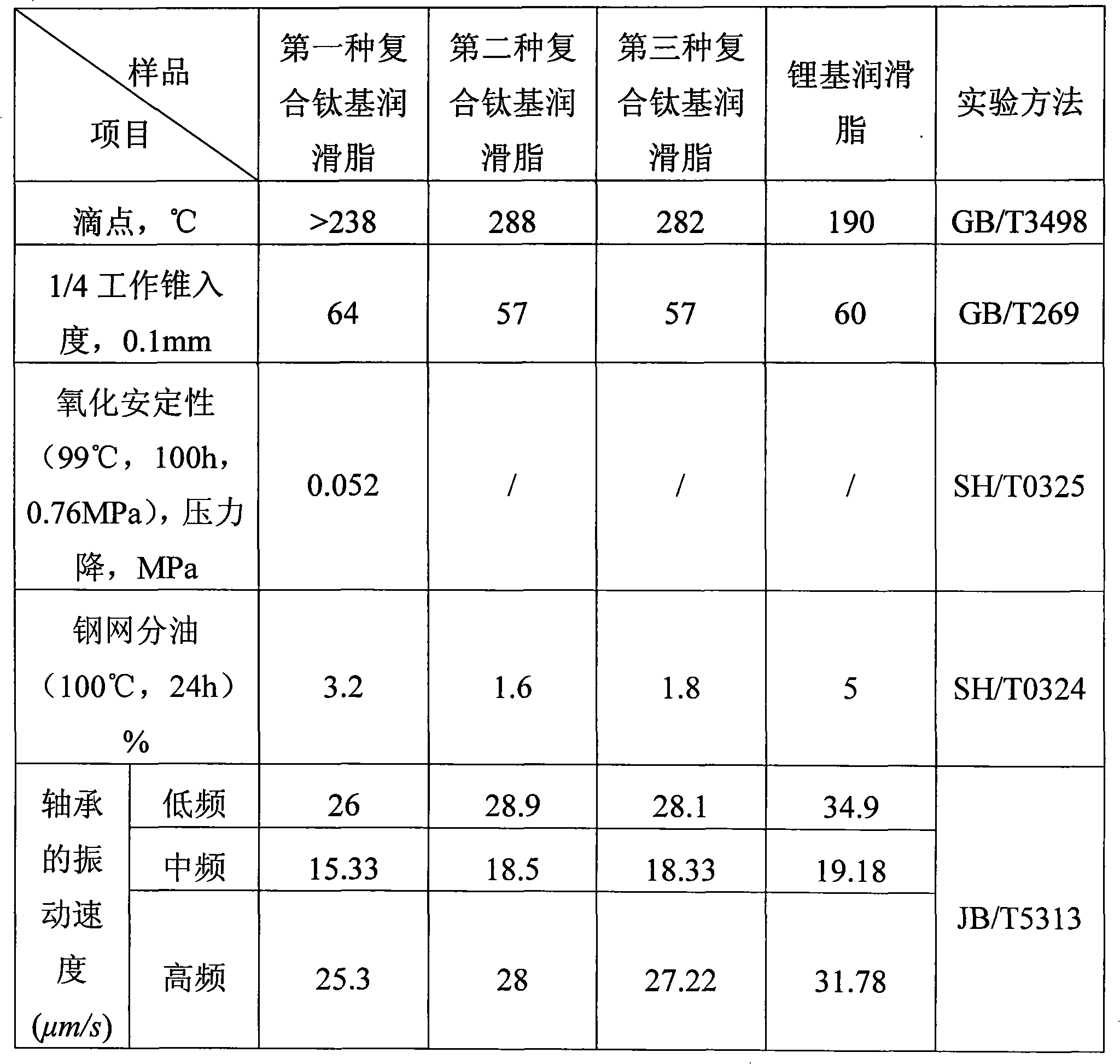

A technology of composite titanium-based lubricating grease and lubricating grease, which is applied in lubricating compositions, base materials, petroleum industry, etc., can solve the problems of unstable vibration speed and noise of lubricating grease, achieve improved oxidation stability, and simple method and process , the effect of excellent conventional physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: The composite titanium-based lubricating grease of the present invention is made of 15-95 parts of base oil, 5-85 parts of thickener and 0.01-5 parts of additives in parts by weight.

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the base oil is dibasic acid diester, sebacate, azelate, neopentyl polyol ester, isoheptyl adipate, Isooctyl adipate, isononyl adipate, isodecyl adipate, isodecyl azelate, isooctyl azelate, isoheptyl sebacate, decanyl Isooctanyl Sebacate, Isononyl Sebacate, Isodecyl Sebacate, Isoheptyl Tridecanoate, Isooctyl Tridecanoate, Isononyl Tridecanoate Esters, Isodecyl Tridecyl Phthalate, Isoheptyl Phthalate, Isooctyl Phthalate, Isodecyl Phthalate, Polyalphaolefin Synthetic Oil or Naphthenic Minerals Oil. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the base oil is naphthenic mineral oil and selected from dibasic acid diester, sebacate, azelate, neopentyl polyol ester, Isoheptyl Adipate, Isooctyl Adipate, Isononanyl Adipate, Isodecyl Adipate, Isodecyl Azelate, Isooctyl Azelate, Decane Di Isoheptyl Sebacate, Isooctyl Sebacate, Isononyl Sebacate, Isodecyl Sebacate, Isoheptyl Tridecanoate, Isooctyl Tridecanoate, Isononyl Tridecyl dioate, Isodecyl Tridecyl Phthalate, Isoheptyl Phthalate, Isooctyl Phthalate, Isodecyl Phthalate and Poly-alpha- One of the olefinic synthetic oils is composed at a mass ratio of 1:0.1-1. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Dropping point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com