Electrolytic ni plating apparatus and method of manufacturing semiconductor device

A device manufacturing method and equipment manufacturing technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as reduced film formation rate, reduced current efficiency, not passivation problems, etc., to prevent current Decrease in efficiency and film formation rate, effect of suppressing passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

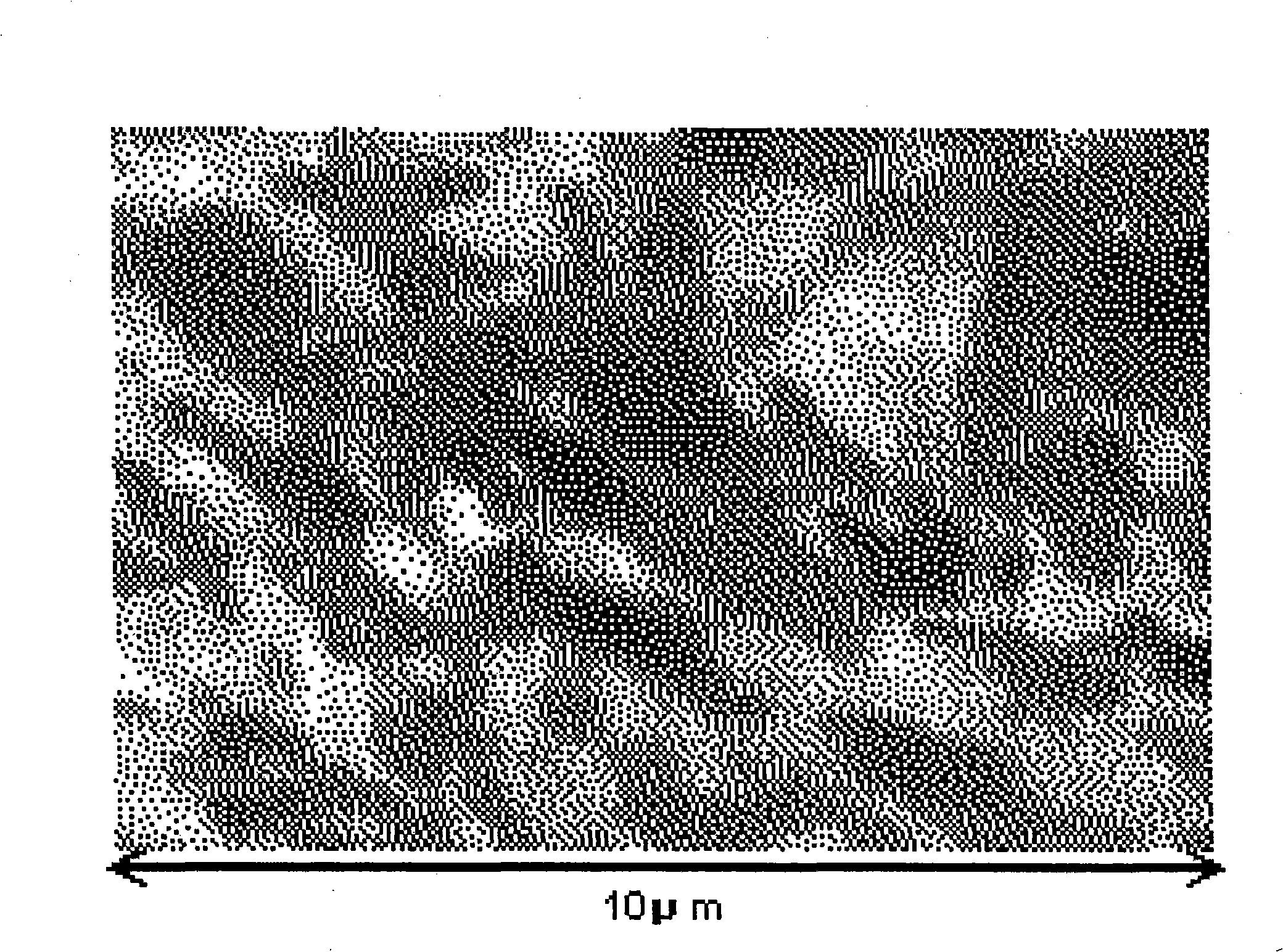

[0035]Wafers were continuously processed at a large current density using an electrolytic nickel plating apparatus provided with a nickel anode having an average grain size of 10 μm or less. The average grain size of the nickel anode is calculated as follows. First, a clean section of the anode is made with a FIB (Focused Ion Beam) device, and then an image of this section is taken with a SIM (Scanning Ion Microscope). image 3 A SIM image of the nickel anode of this example is shown.

[0036] The average grain area S can be obtained by dividing the unit area by the number of grains. In the SIM image of this example, the number of grains per unit area can be counted. The average grain area S is obtained by dividing the unit area by the number of grains counted. Next, the average grain size L was calculated by approximating the grains to a circle in order to convert the area into a length. The average grain size L is calculated by the following formula:

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com