Air exhaust method and apparatus for vacuum-tight sealing of plasma display screen

A technology of plasma display screen and exhaust device, which is applied in the direction of electric tube/lamp exhaust, electrical components, discharge tube/lamp manufacturing, etc. Air difficulties and other problems, to achieve the effect of reducing processing costs, avoiding secondary pollution, and improving the vacuum pumping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

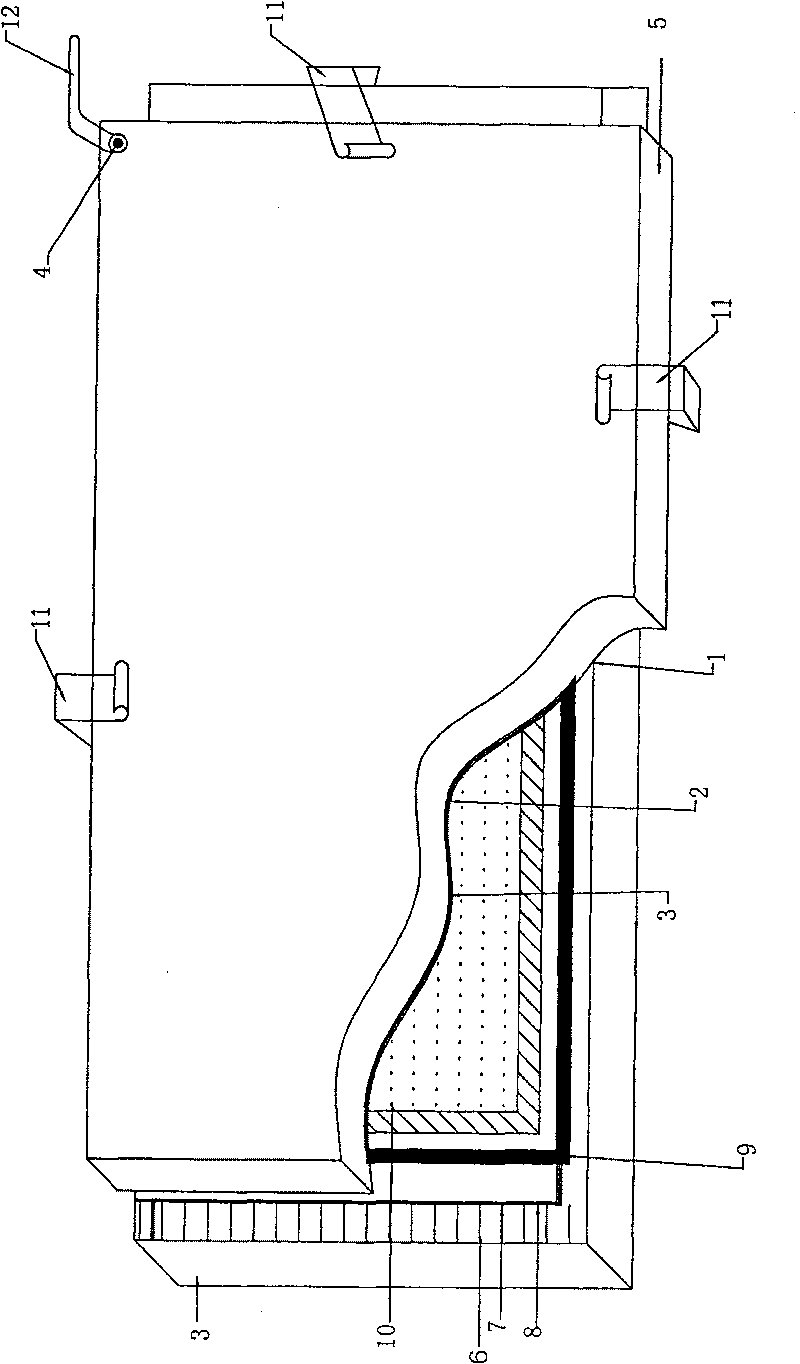

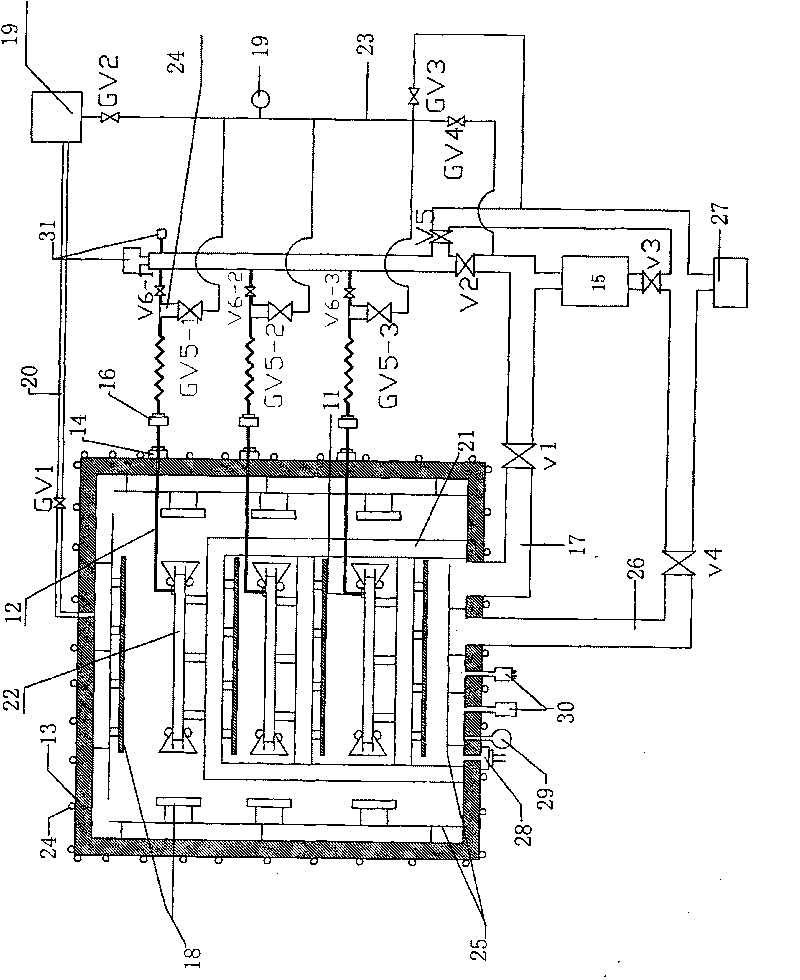

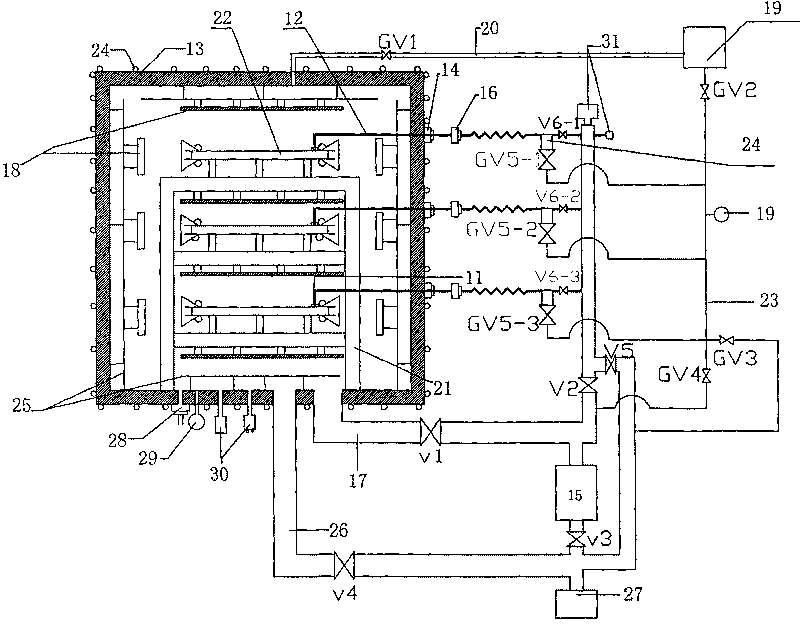

[0030] Such as figure 1 , 2 shown.

[0031] A method for vacuum sealing and exhausting a plasma display screen. Firstly, a rear substrate 5 with an address electrode 1, a dielectric layer 2, a MgO protective layer 3, and an exhaust hole 4 in the non-display area and an addressing electrode are formed. Address electrode 6, dielectric layer 7, MgO protective layer 8, and a shadow mask 10 with phosphor powder layer is sandwiched between the front substrates coated with low-melting point glass powder around the sealing frame 9 for alignment and assembly, and used Sealing clamp 11 is clamped, and with a glass exhaust pipe 12 of custom-made size, the trumpet-shaped one end that is coated with sealing ring is fixed on the exhaust hole 4 with clamp, and the other end is used as the vacuum suction interface of PDP display screen (such as attached figure 1 shown). After the PDP display seal is assembled, place it in a specially designed vacuum sealing exhaust furnace 1 (referred to ...

Embodiment 2

[0035] The process of sealing and exhausting is the same as that of Embodiment 1 in the stages of assembly, temperature rise, heat preservation, and temperature drop until the temperature drops to room temperature. At this time, first close the high vacuum valve V1 of the main pumping pipe 5 and all the high vacuum valve groups V6 for air extraction against the screen, open the valve GV1 for filling the vacuum furnace, and fill the vacuum furnace with N 2 Or various inert gases to a pressure of 0.5-2Pa. Close the inflation valve GV1, and open the high vacuum valve group V6-n for pumping air against the screen one by one at a certain interval. If the high vacuum valve V6-n for pumping air against the screen is opened, the vacuum degree drops significantly , it means that the pair of screens is not sealed well, and there is an air leakage point. The valve should be closed immediately. On the contrary, it means that the screen seal is intact. Close all high-vacuum valve groups...

Embodiment 3

[0037] The process of sealing and exhausting is the same as that of the first embodiment when assembling, heating up, keeping warm, and cooling down until the temperature drops to 360°C to 320°C. Only when the temperature of the vacuum furnace drops to 360°C to 320°C, the sealing frame has been solidified at this time. And start the second embodiment to check whether there is a process step of inflating and detecting screen leakage if the screen is not sealed. And open the high vacuum valve group V6 corresponding to all the well-sealed screens, continuously evacuate until the temperature of the vacuum furnace drops to room temperature, and continue to implement the process steps of filling the working gas according to Case 2 until the finished screen is taken out. At the same time, it needs to be added that when the temperature of the vacuum furnace reaches 360 ° C ~ 320 ° C, the vacuum furnace is filled with N 2 Or various inert gases can increase the cooling rate of the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com