Lithium ionic cell formation processing method

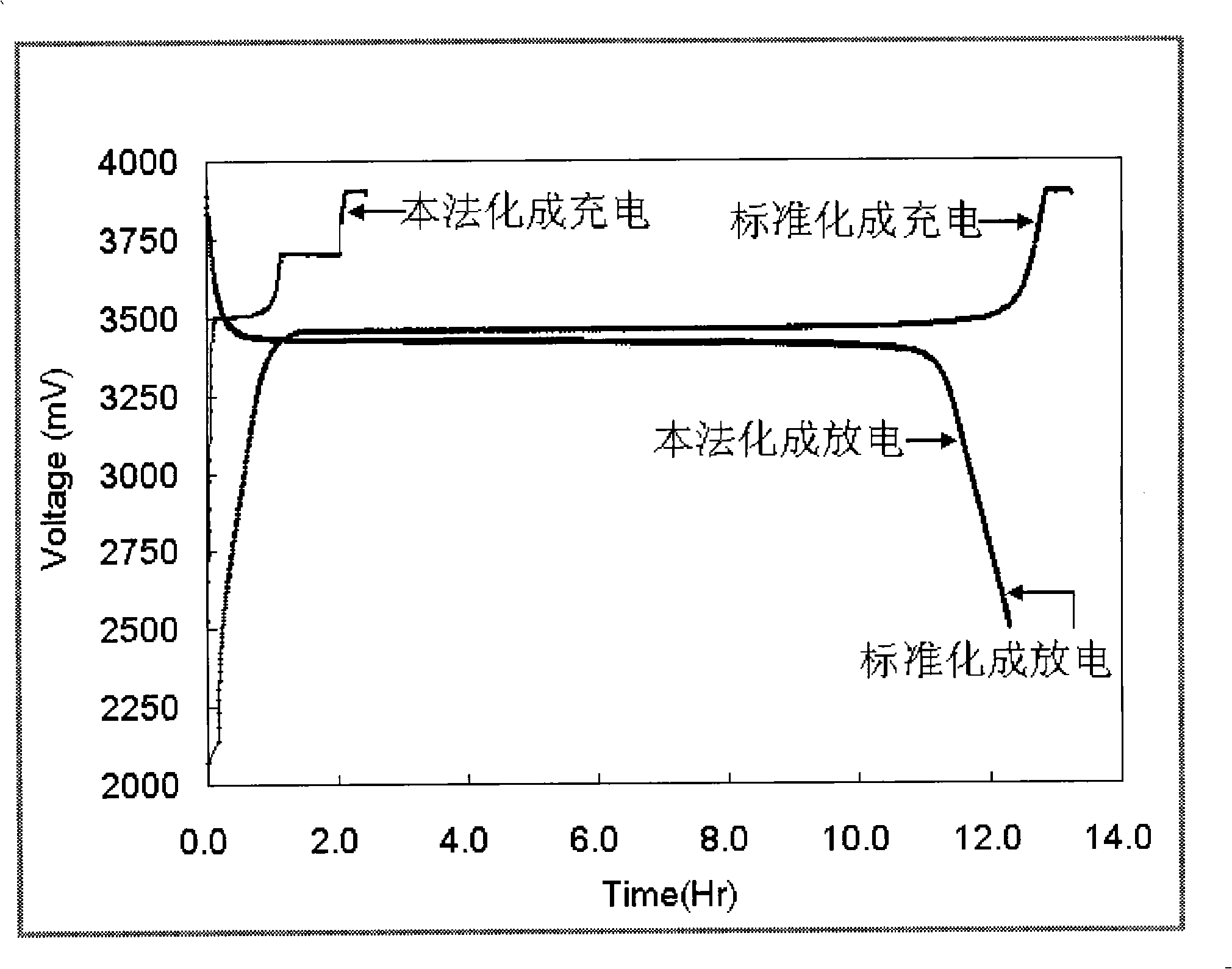

A lithium-ion battery and formation treatment technology, which is applied in secondary batteries, electrochemical generators, non-aqueous electrolyte storage batteries, etc., can solve problems such as safety problems hindering development, long formation time, and large investment in equipment, so as to save equipment Investment and maintenance costs, shortening of formation time, and the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] 1. Fabrication of lithium-ion batteries

[0032] According to mass percentage, 80-98% of lithium iron phosphate, 0.5-2% of conductive additives, 1-4% of polytetrafluoroethylene, with N-methylpyrrolidone or dimethylamide as solvent, at 2000-6000rpm The slurry is adjusted to a slurry under stirring, and the 20um thick aluminum foil is used as a current collector, the slurry is coated on the aluminum foil, and the positive electrode sheet is made into a positive electrode sheet through drying and compacting operations; by mass percentage, 85-92% of MCMB, CMS is used as the negative electrode active material, and 3-11% of KS and SS are used as conductive agents, and 3-11% of polytetrafluoroethylene, polyvinylidene fluoride, and one of polymer resins are used as binders, and N -Methylpyrrolidone or dimethylamide, dimethylacetamide as solvent, stir to make slurry, use 10um thick copper foil as current collector, apply slurry to copper foil, dry and compact and other operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com