Preparation method of anti-human lymphocyte immunoglobulin

An immunoglobulin and lymphocyte technology, which is applied in the field of preparation of anti-human T cell porcine immunoglobulin, can solve the problems of backward ammonium sulfate salting-out method, difficult for ordinary staff to grasp, and high equipment occupancy rate, and achieves reduction of Effects of red blood cell hemolysis, shortened production cycle, and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

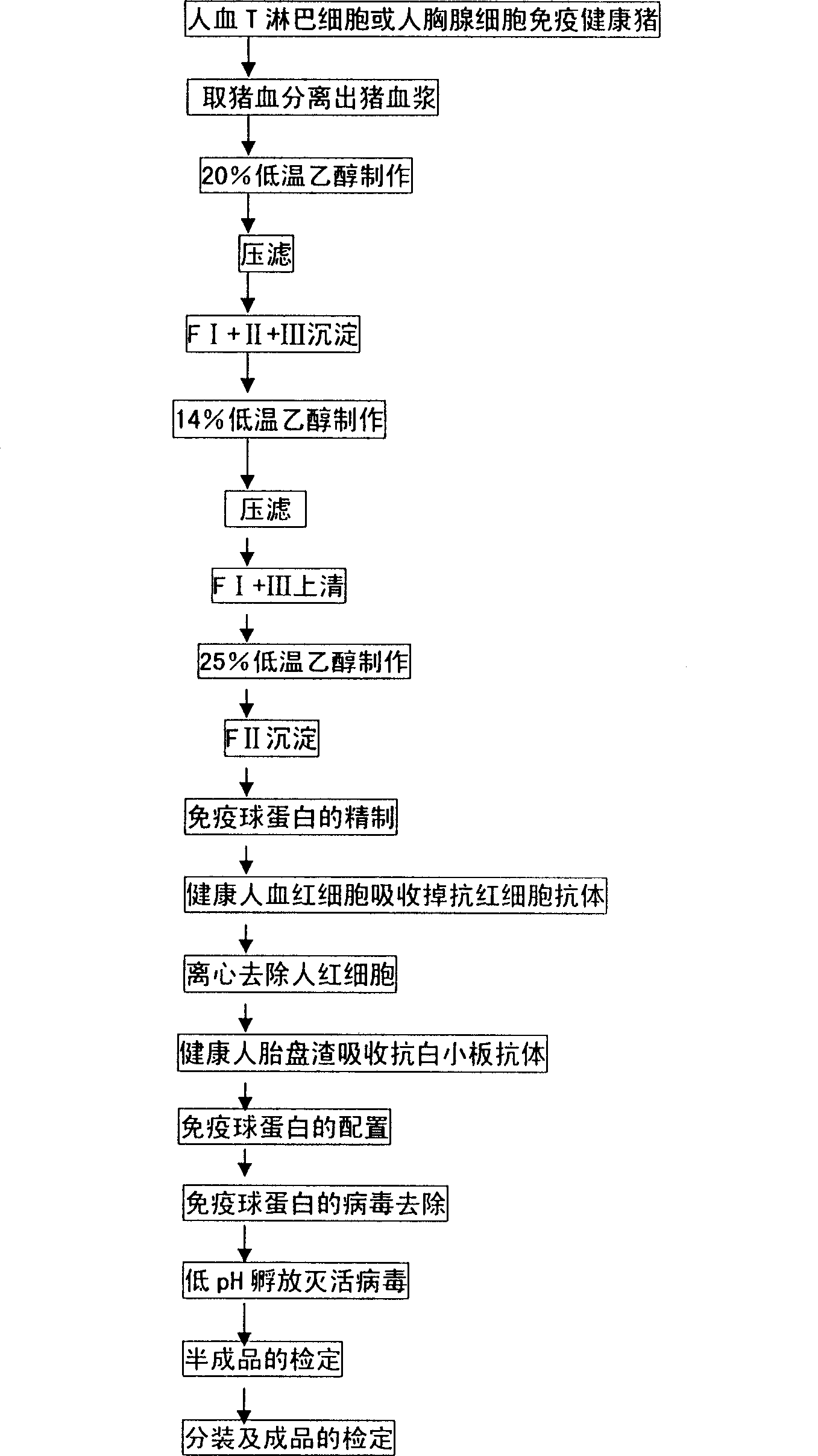

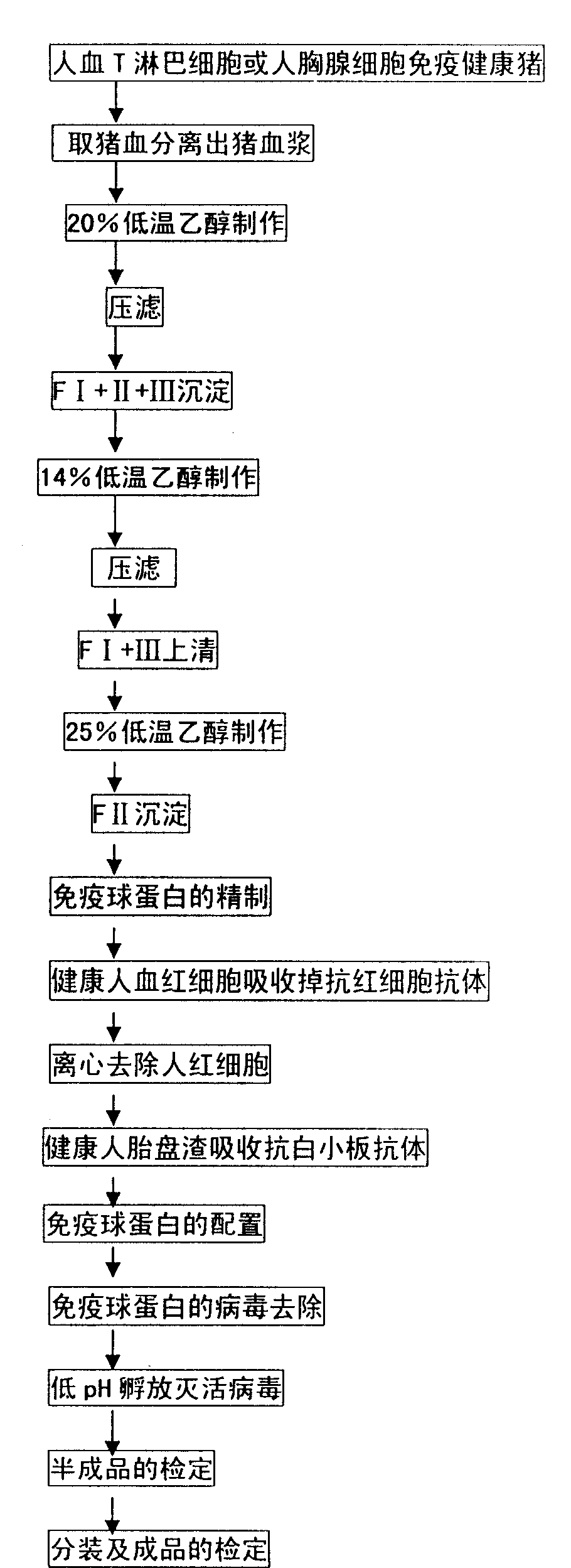

[0038] Embodiment 1 prepares anti-human T cell pig immunoglobulin according to the following process:

[0039] 1. Prepare immune plasma: Use human peripheral blood T lymphocytes or human thymocytes to immunize healthy pigs, collect and separate pig plasma after passing the inspection.

[0040]2. Production of 20% ethanol: Accurately weigh the amount of pig plasma, pour it into a large stainless steel tank, start the stirring paddle to stir slowly, add 20% to 30% of 0.85% physiological sodium chloride solution according to the amount of plasma, stir evenly, and add pH4. 0 acetate buffer solution to adjust the pH value of the mixed solution to 6.0±0.50, then lower the temperature of the mixed solution to -4.0°C±-1.0°C, add 95% ethanol, the temperature of the ethanol should not be lower than -25°C, add Complete ethanol, after continuing to stir for 2 hours, stop stirring and stand still for 8 hours.

[0041] 3. Precipitation and separation of components I+II+III: Use a low-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com