Modification method of white potato slag and application thereof

A potato dregs, potato technology, applied in application, food preparation, food science and other directions, to achieve good physical properties and functional properties, improve product quality, and good water coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1: 1 kg of potato wet residue with a solid content of 8% was added with 5% NaOH solution to adjust the pH of the potato wet residue to 7, heated to 50°C, adjusted to a colloid mill porosity of 12 μm, treated for 8 minutes, and drum dried. , to obtain modified potato residues.

Embodiment 2

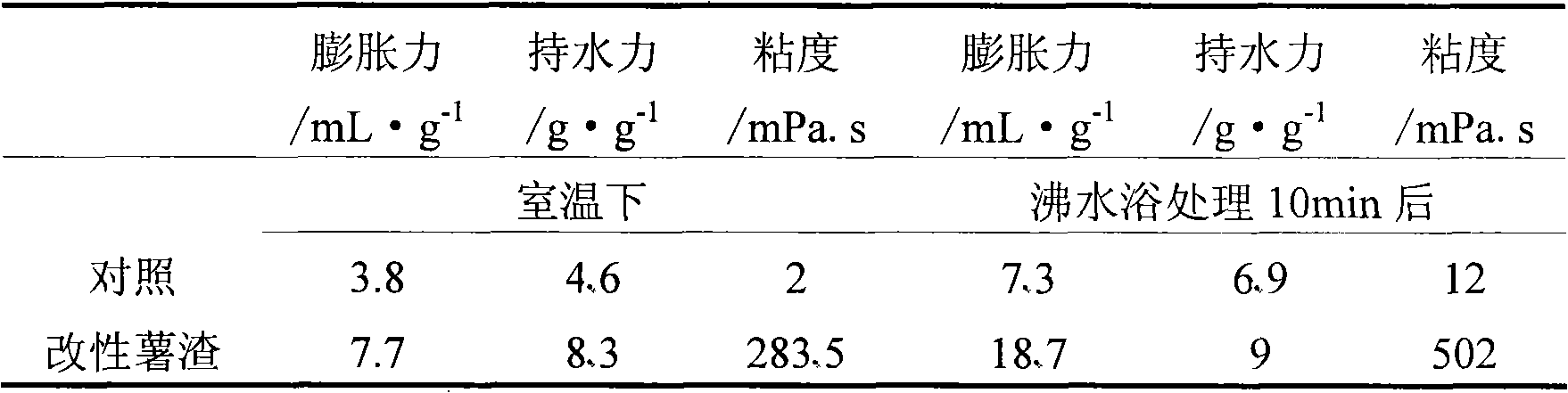

[0010] Example 2: The physical properties of potato dregs before and after modification were compared. Table 1 shows the changes in expansion force, water-holding capacity and viscosity of potato dregs before and after modification. It can be seen from Table 1 that the physical properties of the modified potato dregs have been improved, the swelling force and water holding capacity have increased, and the viscosity that was not exhibited by the modified potato dregs is also obtained.

[0011] Table 1 Changes of expansion force, water holding capacity and viscosity of potato residues before and after modification.

[0012]

Embodiment 3

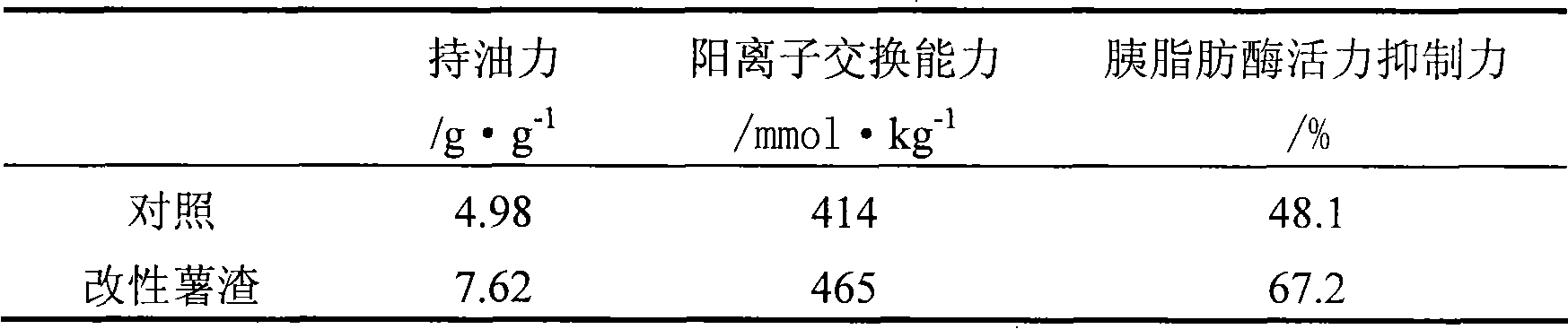

[0013] Example 3: The functional properties of potato dregs before and after modification were compared. Table 2 shows the changes in functional properties of potato dregs before and after modification. Table 2 shows that the modification of the colloid mill improved some functional properties of potato residues related to the ability to lower blood lipids. It was concluded that the hypolipidemic function of the modified potato residues was improved.

[0014] Table 2 Changes of functional properties of potato residues before and after colloid mill treatment

[0015]

[0016] Remarks: The control is potato dregs without colloid mill treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com