Waste gas treating and heat-energy recovering apparatus of heat-setting machine

A technology for waste gas heat recovery and waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

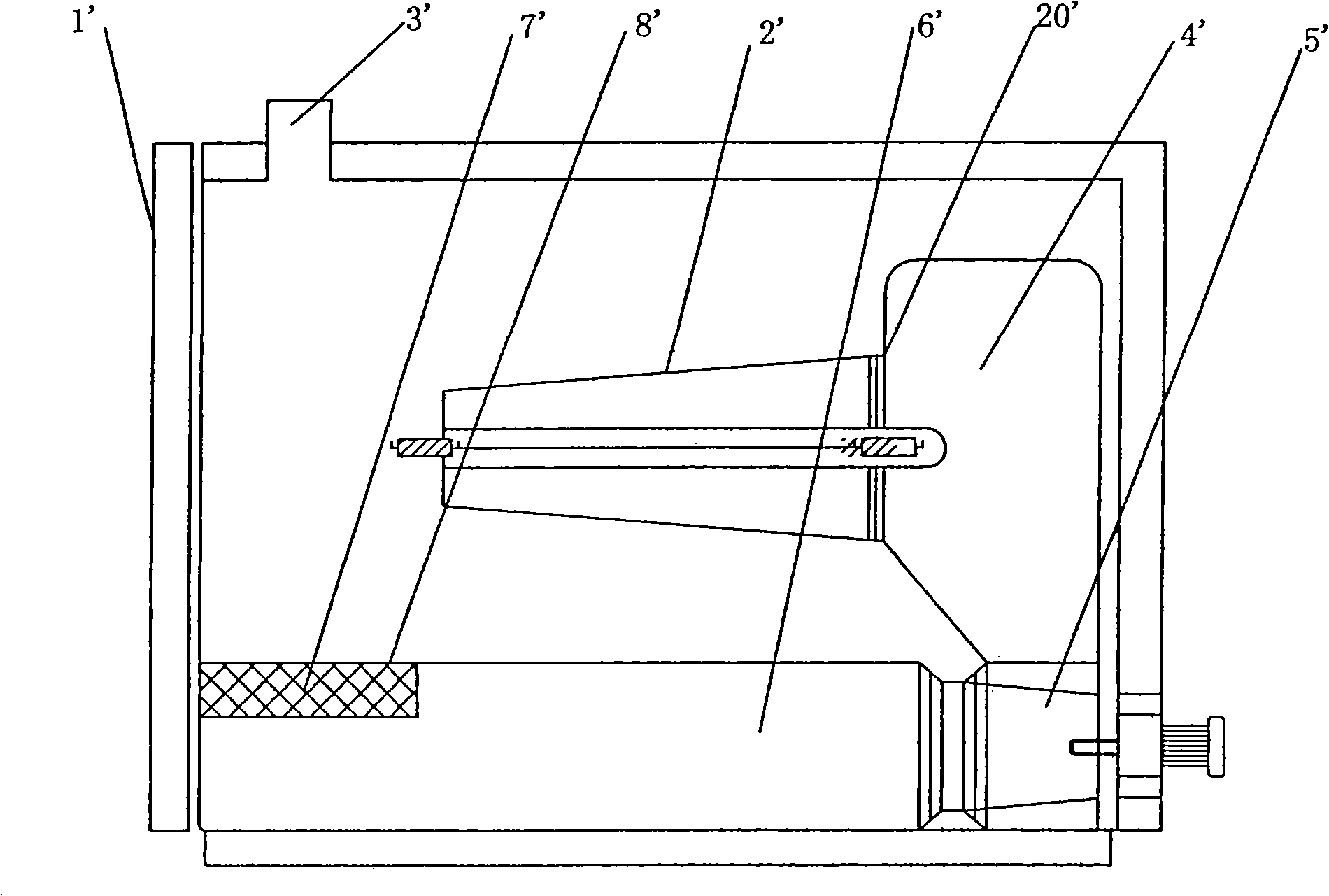

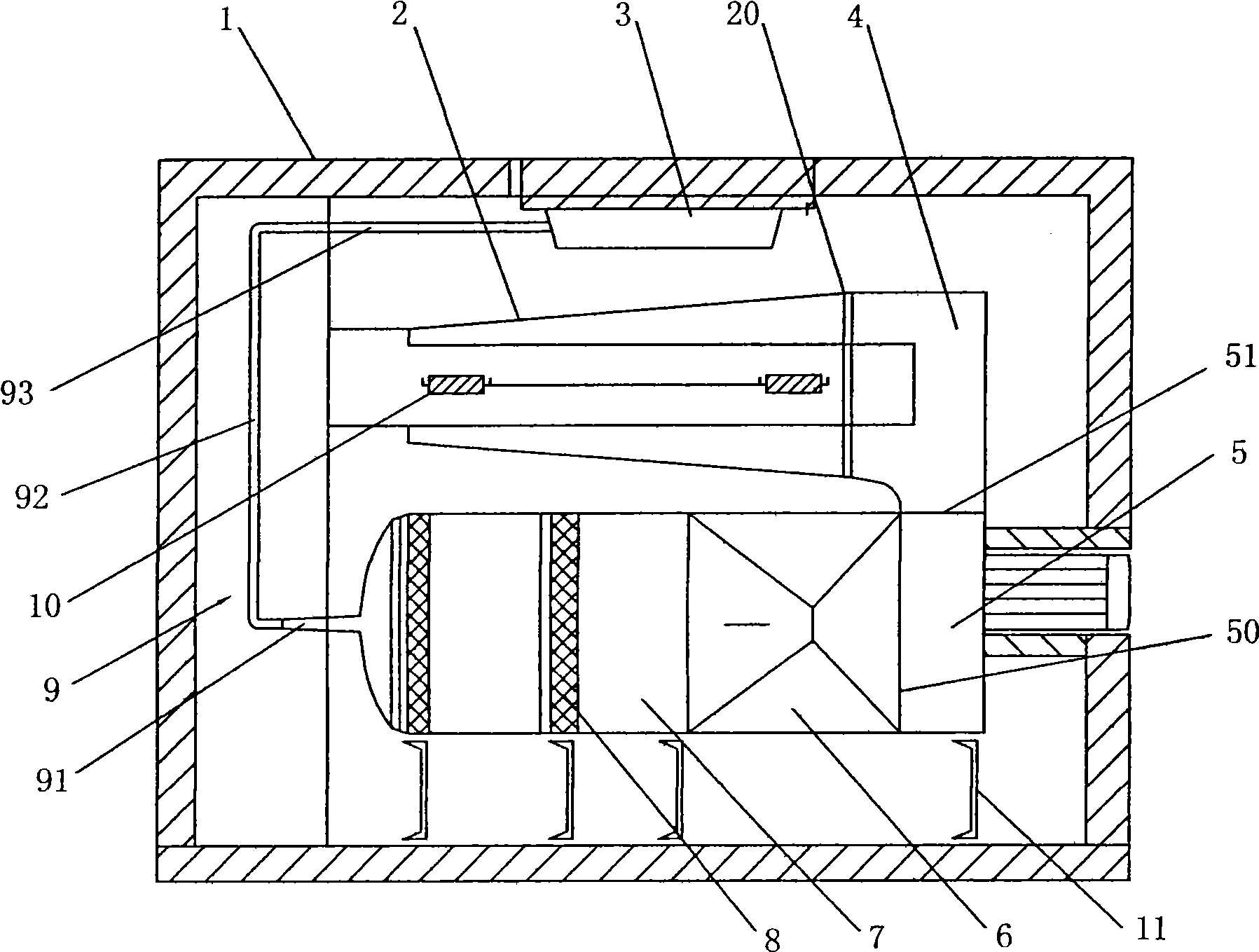

[0025] Please refer to the attached figure 2 As shown, it is a preferred embodiment of the present invention, including an oven 1, in which a hot air pipe 2, a circulating fan 5, an air duct 4, a high temperature purifier 7, an air collecting box 6, an exhaust heat recovery pipe 3 and Lead exhaust gas to take over 9. in:

[0026] The hot air pipe 2 is located at the upper part in the oven 1, and has an air inlet end 20 on its right side.

[0027] Circulation blower 5 has suction end 50 and exhaust end 51, and circulation blower 5 is positioned at the outer side below of the air inlet end 20 of hot blast pipe 2, and is fixed on oven 1 bottom by channel steel 11 and screw rod, nut.

[0028] The lower port of the air duct 4 is connected to the exhaust end 51 on the upper end of the circulating fan 5 , and its left port is connected to the air inlet end 20 of the hot air pipe 2 .

[0029] The high-temperature purifier 7 (the present embodiment is formed by two stages in series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com