Quartz glass crucible, process for producing the same, and use

A quartz glass crucible and quartz glass technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve problems such as liquid leakage, different thermal expansion rates, and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

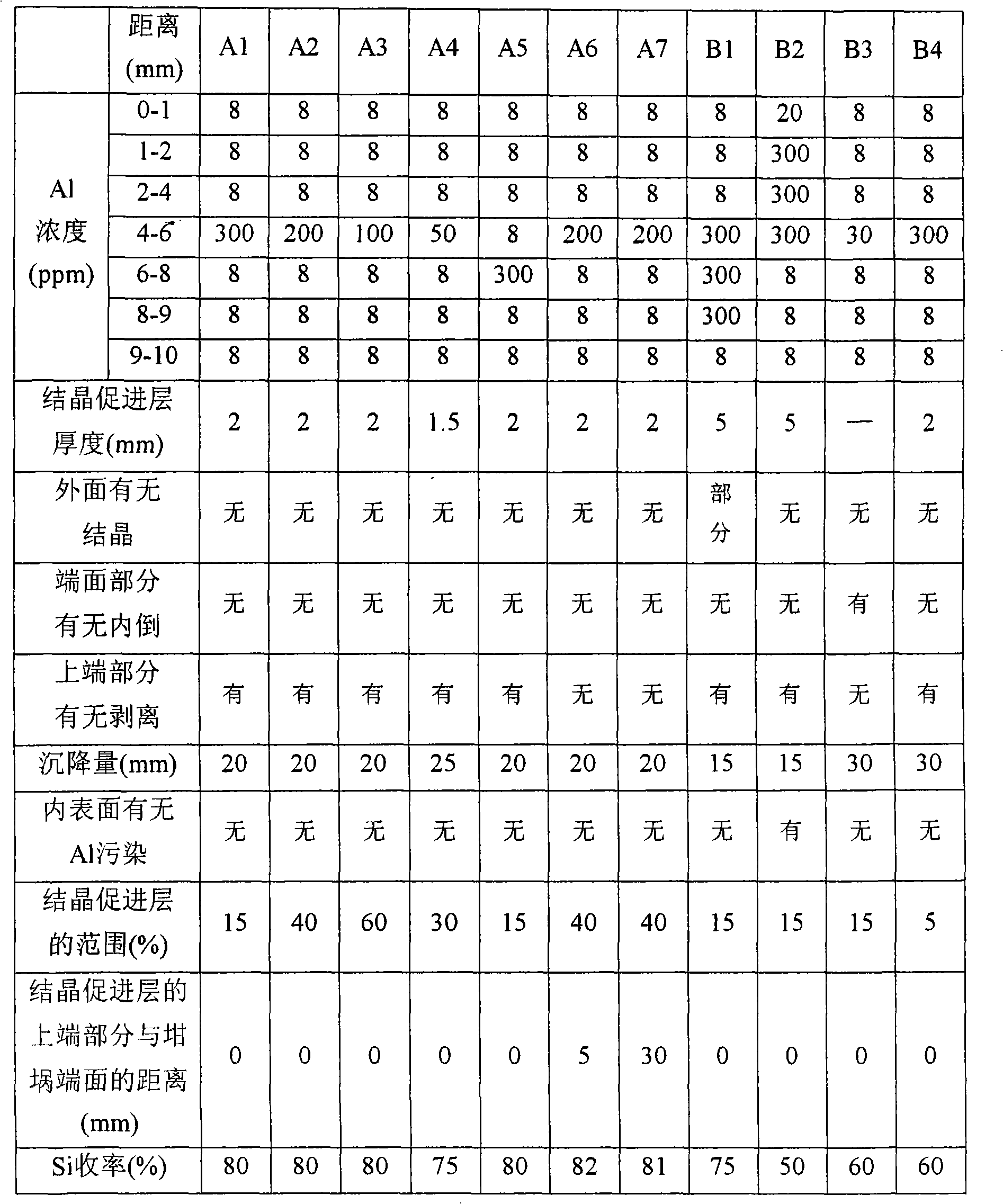

Examples

Embodiment Construction

[0019] The best way to practice the invention

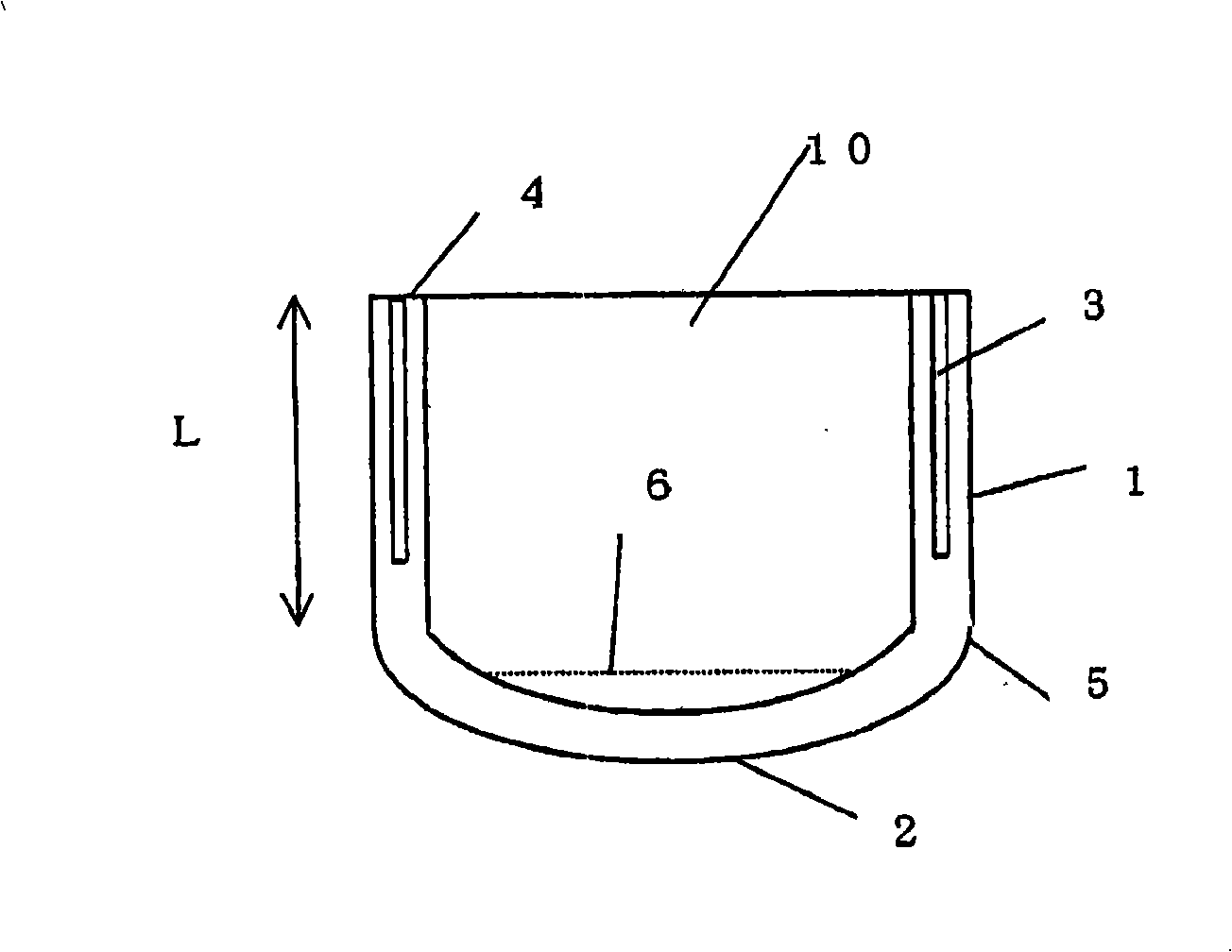

[0020] The quartz glass crucible of the present invention is a quartz glass crucible for pulling silicon single crystals, and is characterized in that: the straight part of the crucible except the bottom of the crucible has a crystallization promoter between the inner layer of the crucible and the outer layer of the crucible. The structure of the component layer (crystallization promotion layer) does not provide a crystallization promotion layer at the bottom of the crucible.

[0021] As for the conventional quartz glass crucible, in the process of investigating the reason why many dislocations occurred in the early stage of silicon single crystal pulling, it was found that in addition to the usual reasons, the peripheral wall of the straight part of the crucible located above the silicon melt surface Deformation or inclination to the inside also plays a big role. When the glass layer is crystallized, the strength at the high te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com