KTP crystal growth method suitable for PPKTP device production

A crystal growth and crystal technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems that quasi-phase matching cannot be realized, the output laser stability decreases, and the X-direction OPO oscillation threshold is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the growth step that is suitable for making the KTP crystal of PPKTP according to the present invention is:

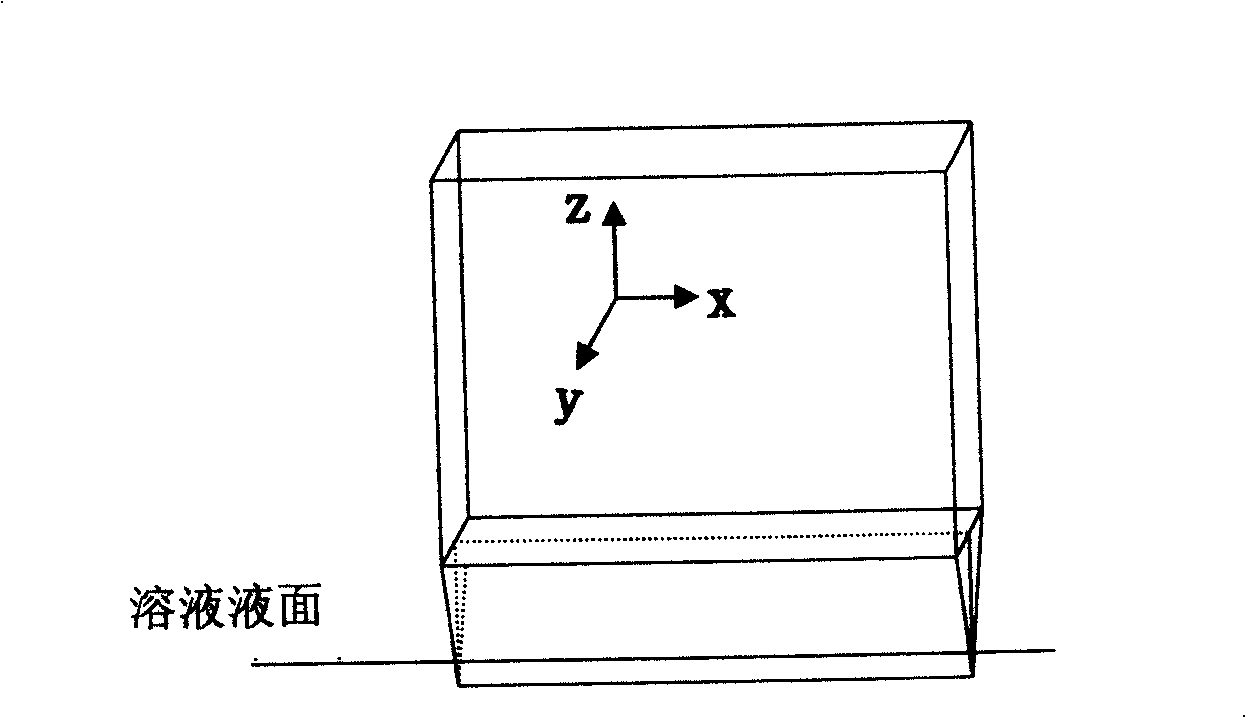

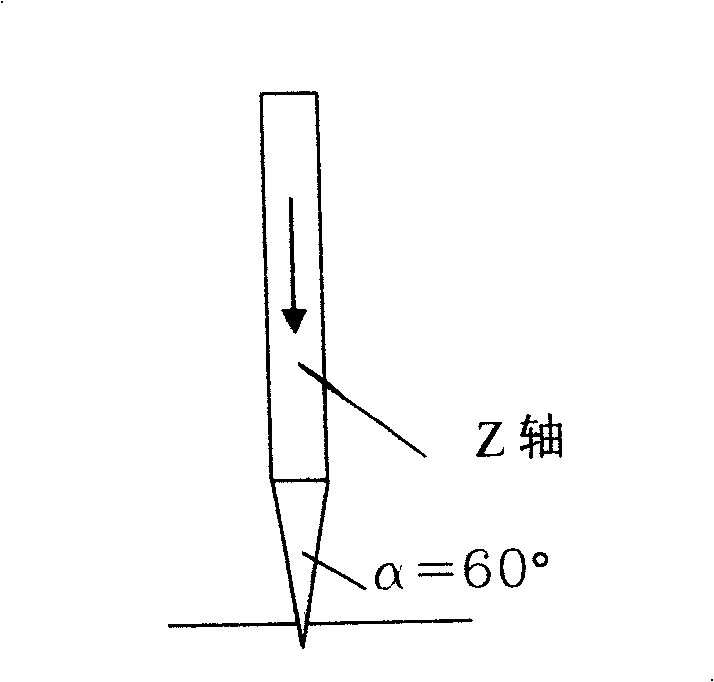

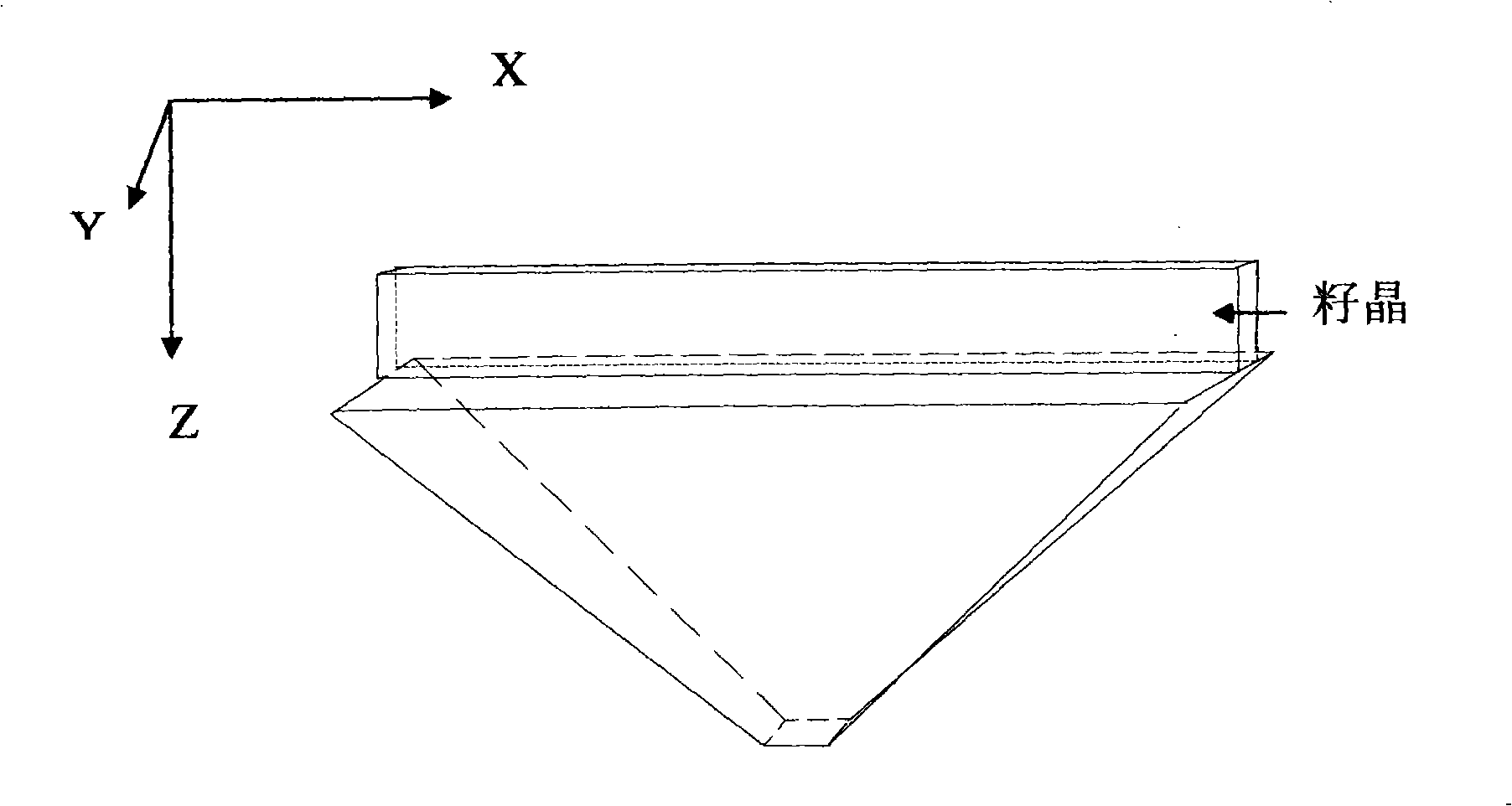

[0028] A) Making the seed crystal: cut a 1mm thick seed wafer along the XZ plane from the KTP original crystal blank with the longest X direction available, process a YZ plane perpendicular to the Z direction at the longest position in the X direction, and then use the center of the Y-Z plane The line is chamfered from the apex to the XZ plane at both ends, and the range of the apex angle α formed is between 0°figure 1 and figure 2 shown.

[0029] B) Immerse the growth surface of the seed crystal into the growth melt, wherein the depth of immersion can be less than 2mm, preferably between 0.5mm-1mm, to grow the crystal.

[0030] The growth melt in this step is the K6 flux KTP melt synthesized at high temperature. The preparation method is: calculate the KH2PO4, K2HPO4, TiO2 raw material weight according to the obtained KTP and K6 ratio, mix them,...

Embodiment 2

[0043] Select high-quality seed crystals with a length of 45mm in the X direction. It is required that the seed crystals have no cracks and no macroscopic interlayers on the growth surface of the seed crystals. They are processed into 20mm high Z-direction, 1mm thick flakes, and the 45mm long X-direction side with better quality is pressed 60 degrees. Process the growth surface at the top angle, put it into a saturated solution with a ratio of KTP:K6=1.186mol:1mol, rotate the seed crystal at 15 rpm, put in fragmented crystals and make them grow until the side length is about 5mm. Friction roughening The X surface of the growing crystal is cooled slowly and grows after two months. According to the requirements, the X-direction 55mm long seed crystal is cut and the growth surface is processed, and the growth is carried out again under this system, but no broken crystals are used for this growth. And control the solution so that there is no spontaneous crystallization, and grow ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com