Capacitor type horizontal shaft micro-mechanical tuning fork gyroscope

A tuning fork gyroscope, horizontal axis technology, applied in the direction of speed measurement, gyroscope/steering sensing equipment, instruments, etc. with gyro effect. Gyro stress and other problems, to achieve mass production, reduce aging and temperature test requirements, increase detection quality and detection capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] For the convenience of describing the present invention, the structures of the two double-terminal unequal-height vertical comb capacitors involved in the present invention are firstly described.

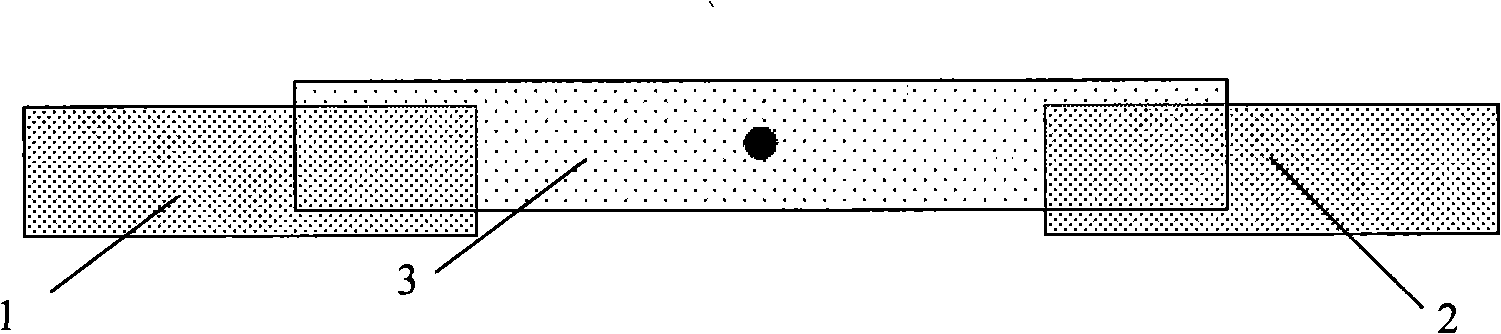

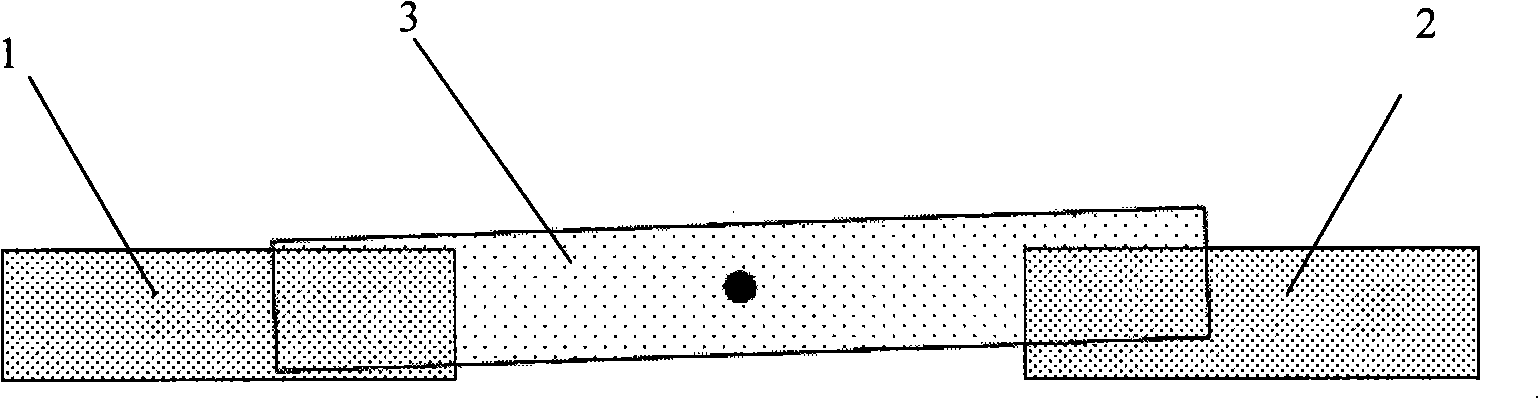

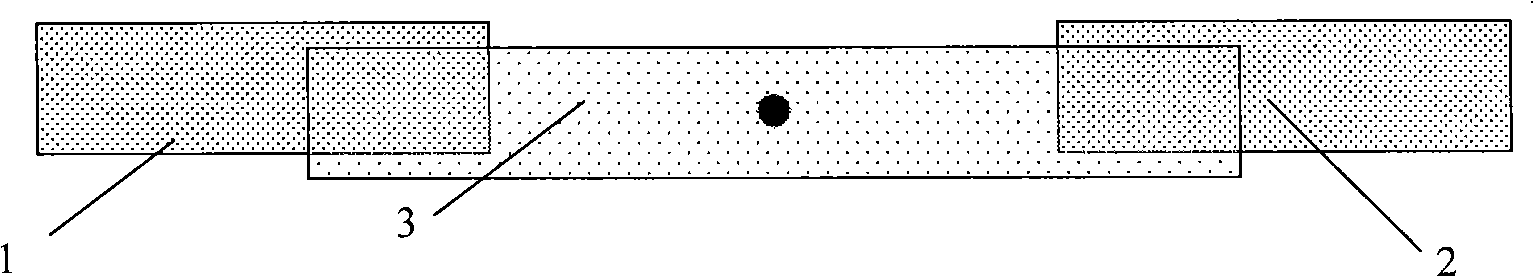

[0023] Such as figure 1 , figure 2 As shown, the double-terminal unequal height comb capacitor type I includes the movable electrode 3 with the same thickness and the fixed electrodes 1 and 2 adopt a double-terminal unequal height structure, that is, the top and bottom of the movable electrode 3 are higher than the fixed electrodes. 1, 2 top and bottom. The movable electrode 3 and the fixed electrode 1 form a sensitive capacitance C 13 , the movable electrode 3 and the fixed electrode 2 form a sensitive capacitance C 23 . At the initial position (such as figure 1 shown), two sensitive capacitors C 13 and C 23 The overlapping areas of the electrodes are the same, and the values are equal. When the movable electrode 3 is twisted counterclockwise at a small angle (suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com