Method for preparing aluminum/lead system laminar composite material metallic phase example and display organization

A composite material and sample technology, applied in the field of metallographic sample preparation, can solve the problems of low melting point, difficult to eliminate polishing marks, and relief, etc., and achieve the effect of simple preparation method, high definition and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

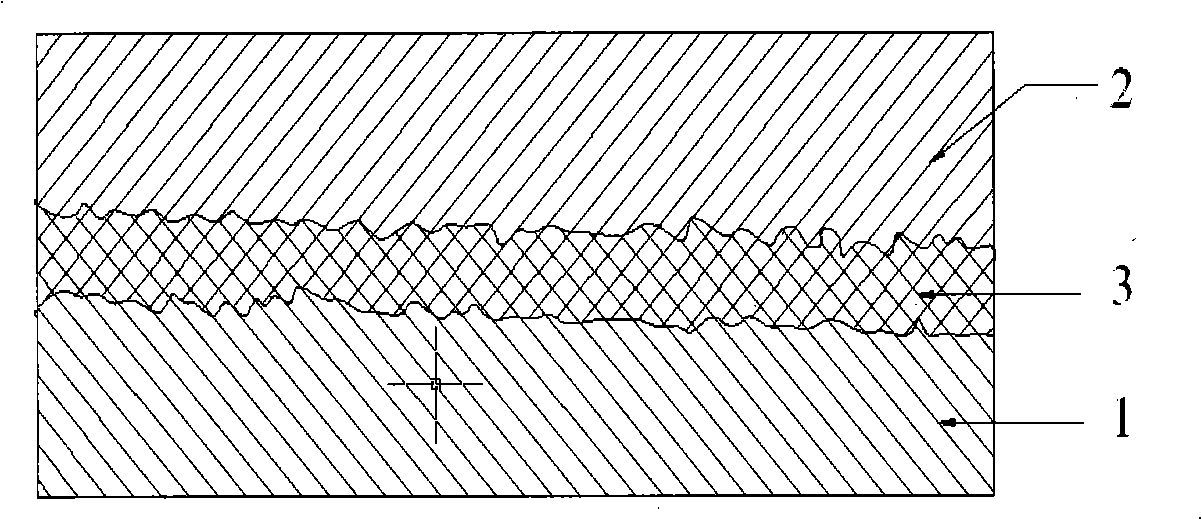

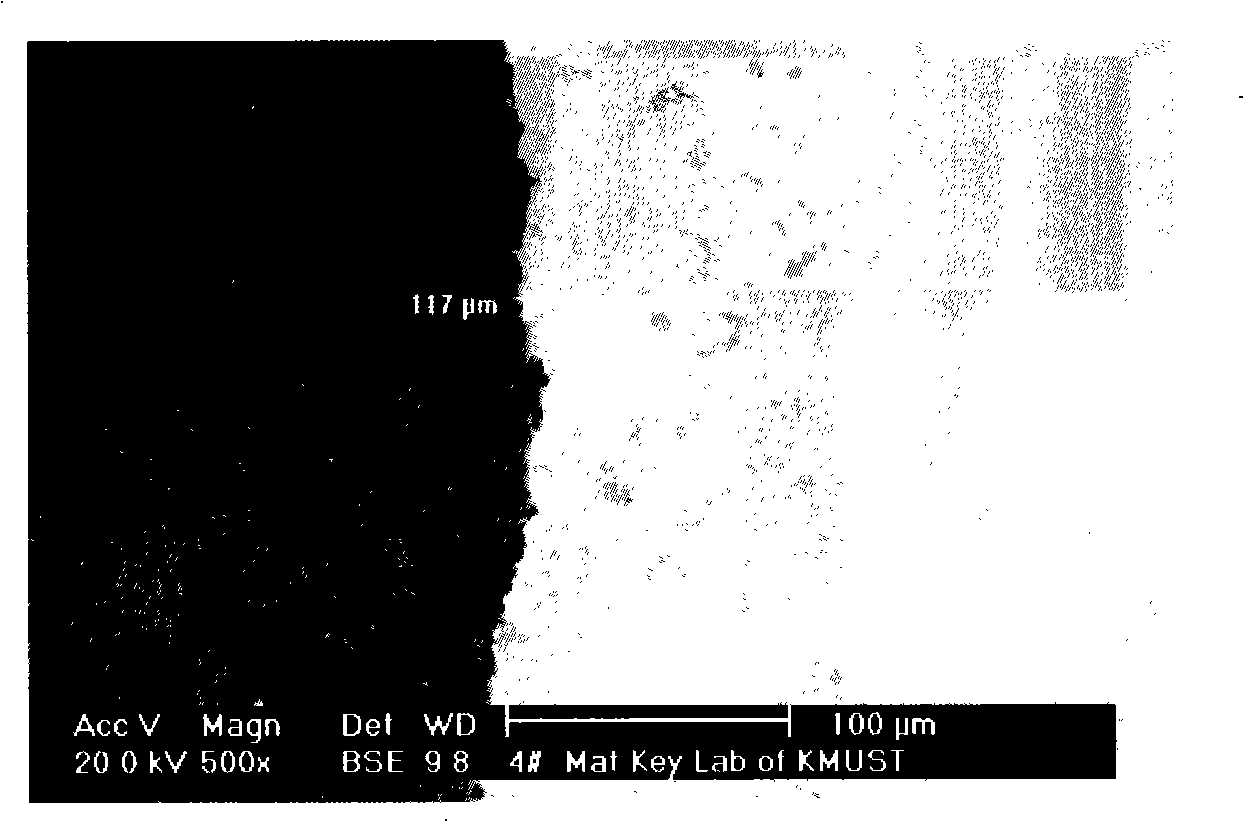

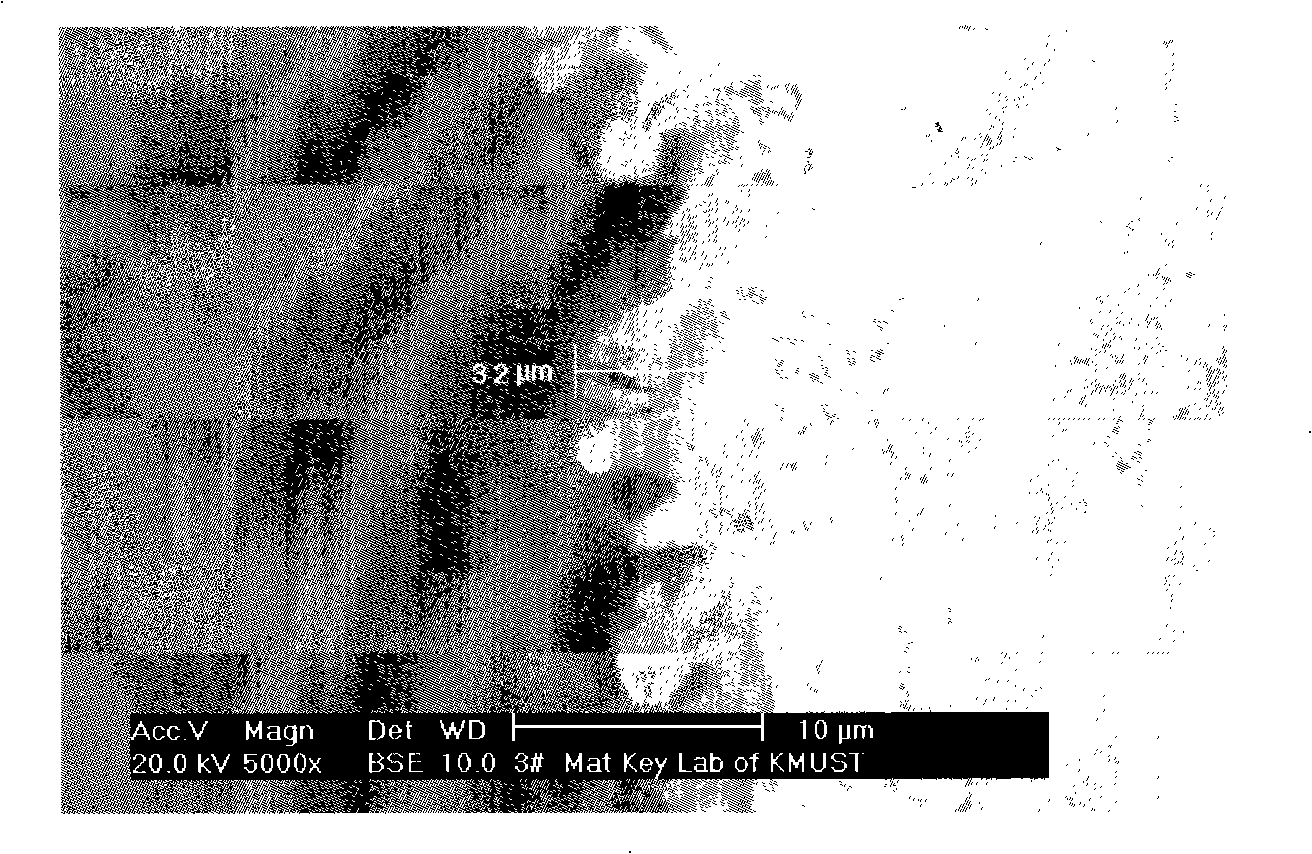

[0025] Example 1 as figure 1 As shown, in the figure 1 is the aluminum bottom layer of 100×20×3mm, 2 is the lead surface layer of 100×20×3mm, and 3 is the transition metal layer tin layer of 100×20×1.Omm. The sample preparation goes through the following steps: A. Cutting and inlaying the sample: Use sharp-edged scissors to cut a sample of an appropriate size in cold water, dry it naturally in the air, file the cross-section with a fine plate, and use polytetrafluoroethylene The cylinder with a diameter of 25mm and a length of 15mm is used as a casing, and the high-grade general-purpose double-tube adhesive with short curing time and low heat release is used as a curing filler. When forming a sample, place it on a smooth flat plate and cure it naturally in the air for 8 hours.

[0026] B. Manual coarse grinding: the sample has been passed through 320 # 、600 # , 800 # Silicon carbide water sandpaper is manually polished, and continuous tap water is used as lubricant and cool...

Embodiment 2

[0030] The sample preparation step of embodiment 2 is basically the same as that of embodiment 1, and the difference is that the transition metal layer 3 is a bismuth layer, and the time for the sample to be solidified in the air in step A is 6 hours, and the rough polishing time in step D is 7 minutes. In step E, the working parameters of the frequency converter are 22Hz, 380V. Every 3 minutes of polishing, dip HNO with absorbent cotton 3 5ml+C 2 h 5 Wipe OH95ml erosion solution on the grinding surface for 15 seconds, dip HF (48%) 0.5ml+H with absorbent cotton 2 Wipe 095ml etching solution on the grinding surface for 10 seconds, other steps are the same as case 1, and the clarity of metallographic structure obtained is similar to case 1.

Embodiment 3

[0031] Example 3 The sample preparation steps are basically the same as in Example 1, except that the solidification time of the sample sample in the air is 7 hours in the step A, the rough polishing time in the step D is 10 minutes, and the frequency converter works in the step E The parameter is 20Hz, 380V, every polishing 3 minutes, dipped in HNO with absorbent cotton 3 5ml+C 2 h 5 Wipe OH95ml erosion solution on the grinding surface for 25 seconds, dip HF (48%) 0.5ml+H with absorbent cotton 2 Wipe 095ml etching solution on the grinding surface for 15 seconds, other steps are the same as case 1, and the clarity of metallographic structure obtained is similar to case 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com