Magnetorheological finishing device for super large caliber aspheric surface optical part

A technology of magnetorheological polishing and optical parts, which is applied in the field of magnetorheological polishing, can solve problems such as unguaranteed, fixed workpieces, and excessively long pipeline connections, so as to avoid flow fluctuations and flow velocity fluctuations, ensure processing accuracy, The effect of ensuring surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

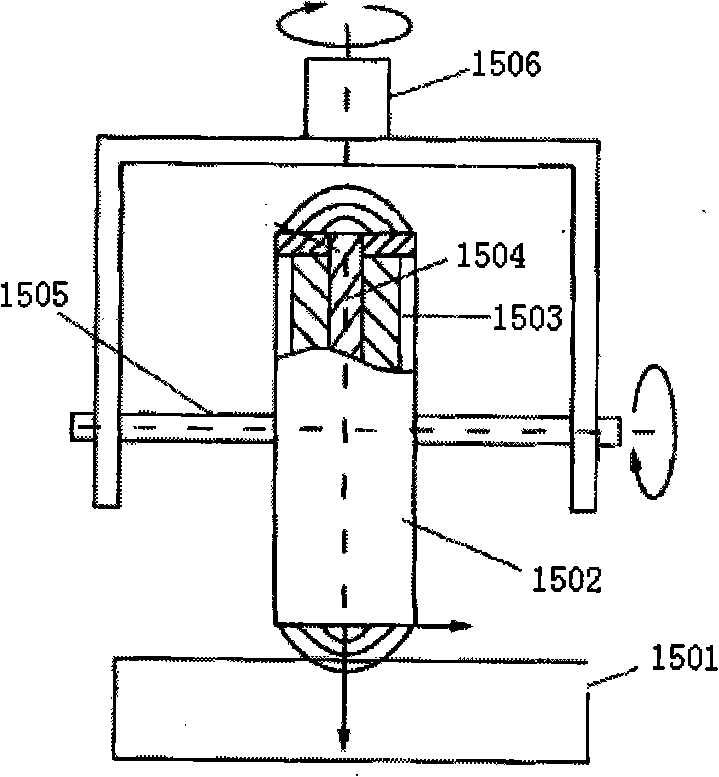

[0095] Such as Figure 4As shown, the magnetorheological polishing device for ultra-large-diameter aspheric optical parts of the present invention includes a machine tool 1, a magnetorheological polishing device 2 and a control system connected to each of the above components respectively. On the bed 101 of the workpiece 10 and the X-axis linear motion mechanism 3, the movable gantry 4, the Y-axis linear motion mechanism 5, the Z-axis linear motion mechanism 7, the fourth linear motion mechanism 513 and the A-axis turntable 9, The X-axis linear motion mechanism 3 is arranged on both sides of the bed 101, the two columns 401 of the movable gantry 4 are respectively fixed on the sliders of the X-axis linear motion mechanism 3, and the Y-axis linear motion mechanism 5 is arranged on the movable On the beam 402 of the moving gantry 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com