Multicomponent compound infrared crystal growth method

A crystal growth and compound technology, applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of solid-liquid interface drift, small temperature gradient, large difference in melting point, etc., and achieve complete appearance and good crystallization performance. , the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

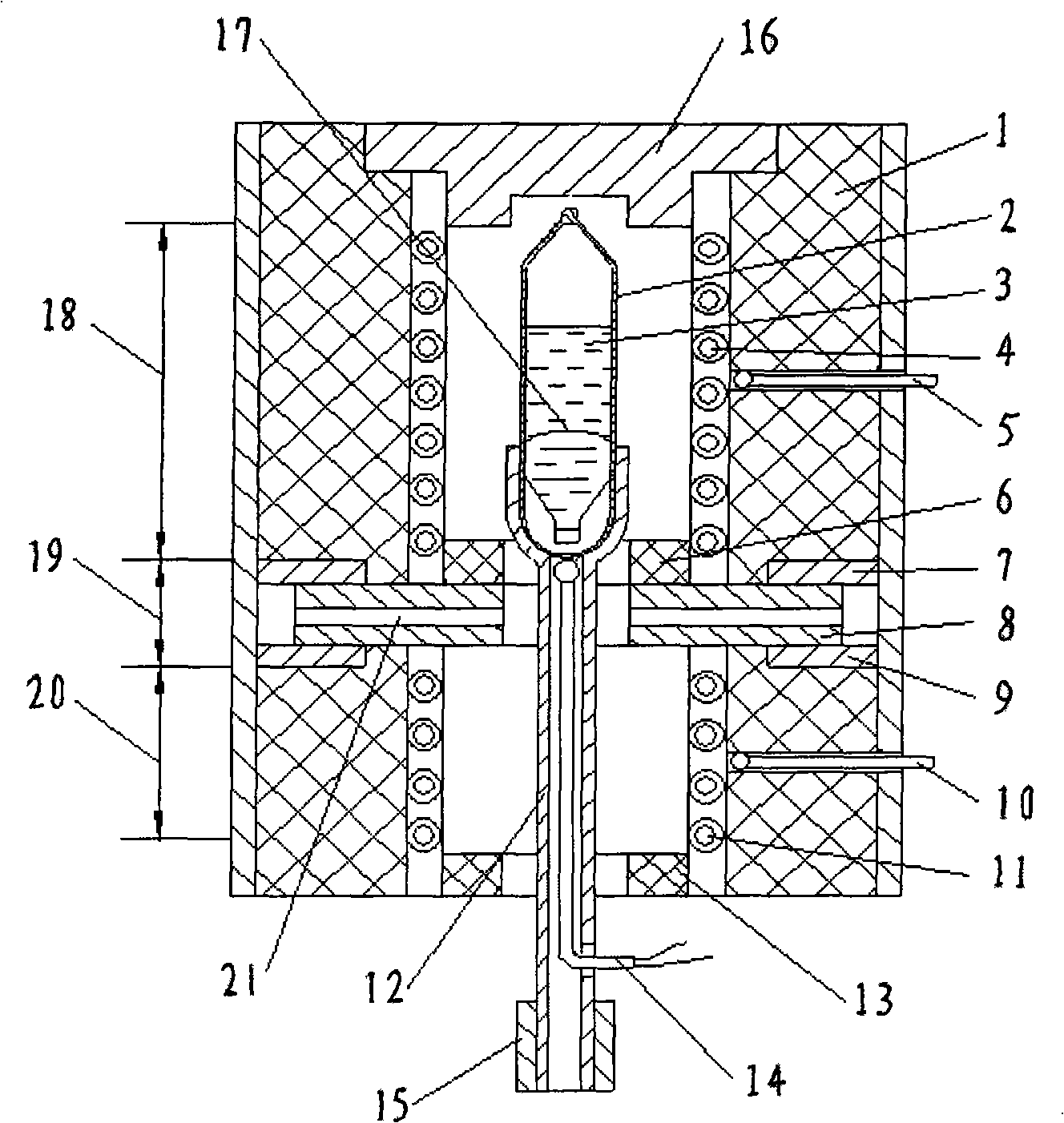

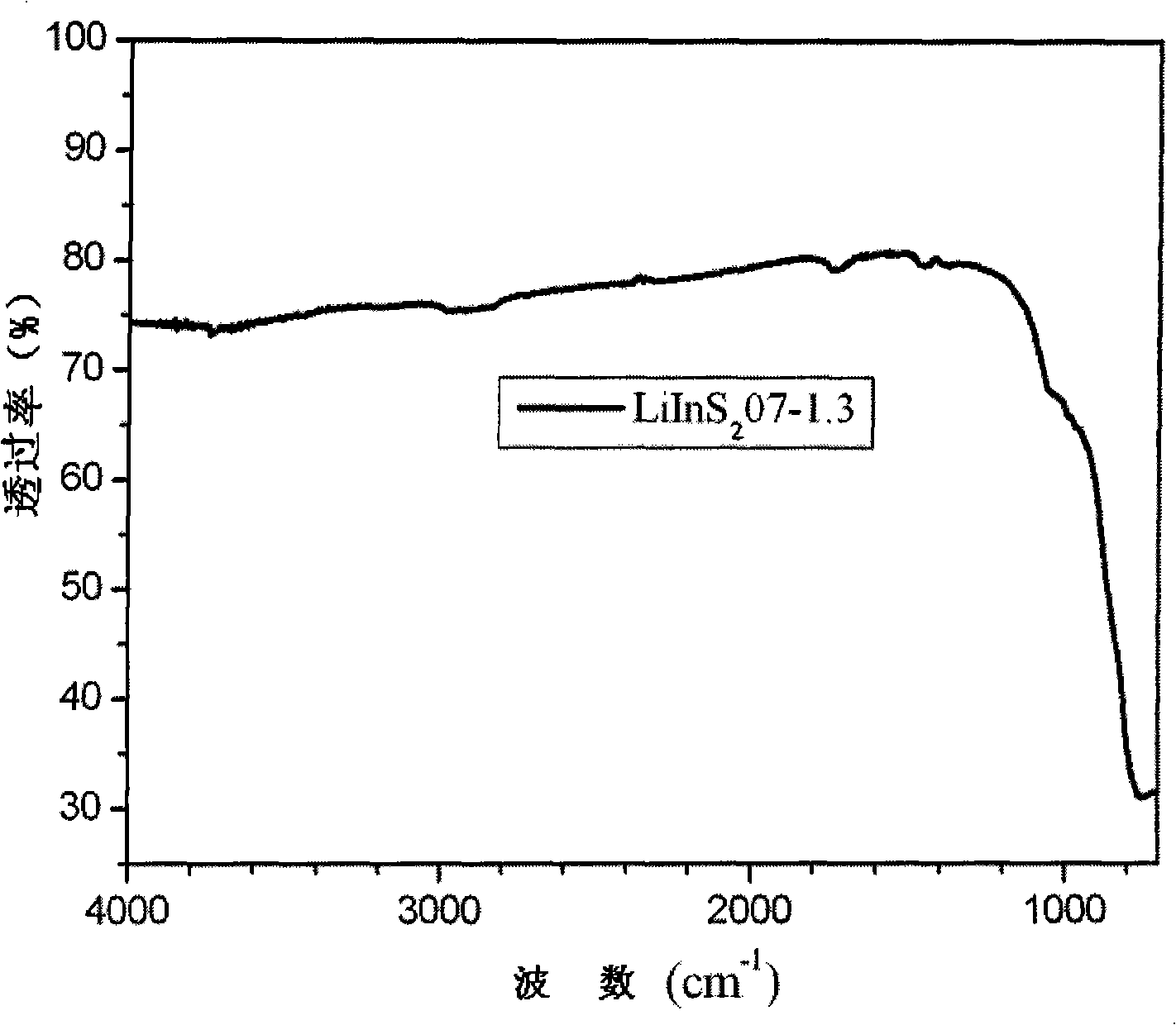

[0022] Example 1: Infrared Crystal LiInS 2 growth

[0023] Take LiInS 2 Polycrystalline powder is used as a raw material, and the polycrystalline powder raw material is loaded into a graphite crucible 3, and then sealed in a quartz tube 2, and the crystal growth is carried out according to the following process steps:

[0024] (1) Clean the quartz tube 2:

[0025] Soak in aqua regia solution for 24 hours to remove metal ions attached to the wall of the quartz tube, then soak in acetone for 24 hours to remove organic impurities attached to the wall of the quartz tube, then soak in dilute hydrochloric acid solution for 5 to 10 minutes, and finally use Rinse with deionized water and dry in an oven for later use. At the same time, the crucible is cleaned to remove impurities on the inner wall of the crucible.

[0026] (2) Charge and vacuumize, seal the quartz tube 2:

[0027] Weigh 10g~20g LiInS 2 The polycrystalline powder is loaded into a graphite crucible 3 with a tempera...

Embodiment 2

[0034] Example 2: Infrared Crystal ZnGeP 2 growth

[0035] Using ZnGeP2 polycrystalline powder as the raw material, the polycrystalline raw material is put into the graphite crucible 3 and then sealed into the quartz tube 2 . Crystal growth includes the following process steps in sequence:

[0036] (1) Clean the quartz tube 2 and the crucible 3 as described in Example 1.

[0037] (2) Charge and vacuumize, seal the quartz tube 2:

[0038] Weigh 10g~20g ZnGeP 2 The polycrystalline powder is loaded into a graphite crucible 3 with a temperature-measuring thermocouple 14 placed at the tip, and then the charged graphite crucible 3 is loaded into a cleaned quartz tube 2, and then heated to 200°C to 300°C on an electric furnace for pumping. Vacuum, when the vacuum degree in the crucible reaches 10 -3 ~10 -4 pa, seal the quartz tube with an oxyhydrogen flame.

[0039] (3)ZnGeP 2 crystal growth

[0040] a. Put the sealed quartz tube into figure 1 In the hearth of the growth fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com