Yawing mechanism of wind power generator

A technology of wind turbines and yaw mechanisms, which is applied in the field of yaw mechanisms, can solve the problems that large and medium-sized wind turbines are not suitable for use, and achieve the effect of increasing bearing capacity and reducing fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

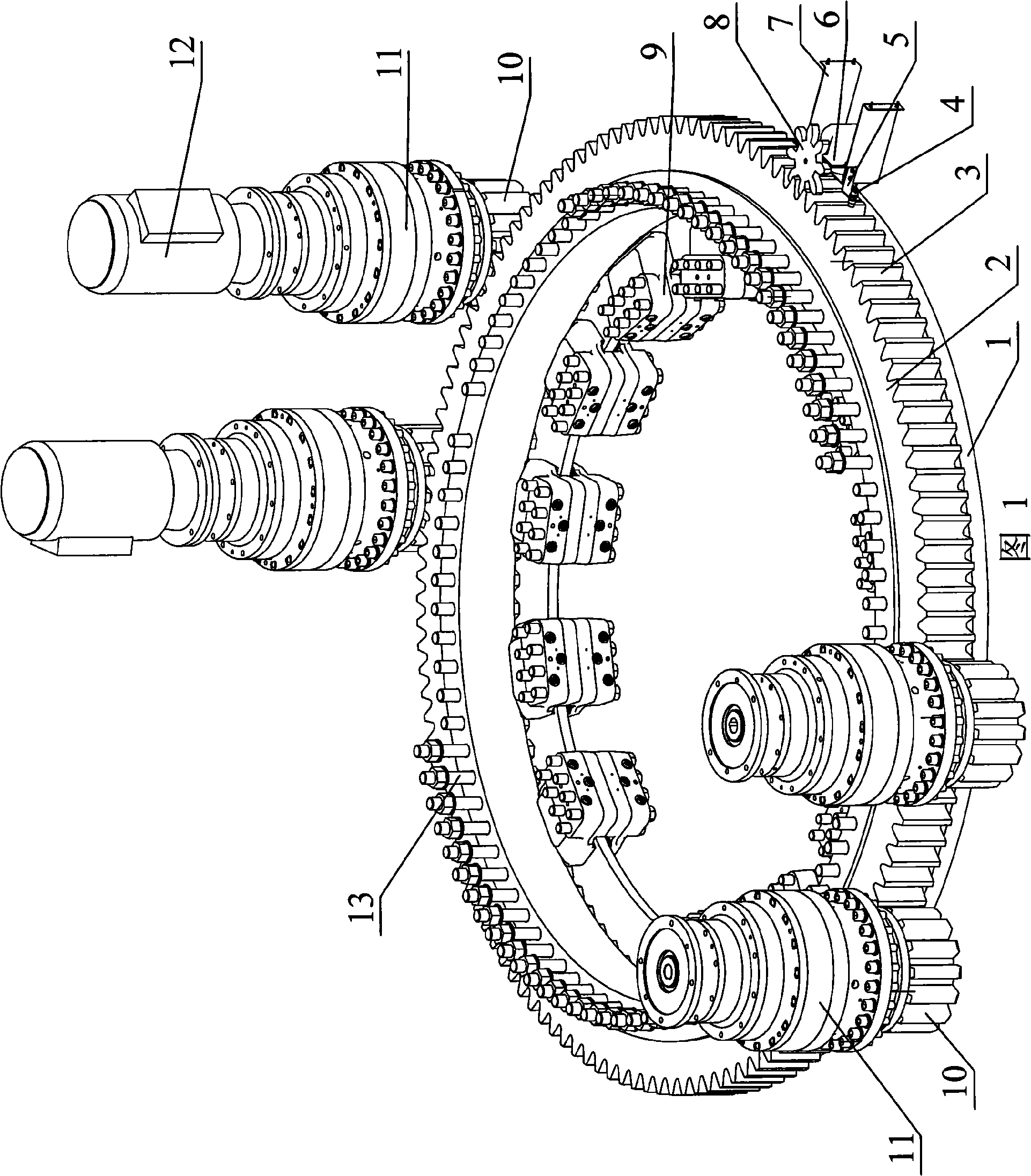

[0010] As shown in the figure: on the top of the annular brake disc 1 is a ring-shaped slewing bearing 2 connected to each other, teeth 3 are arranged on the outer edge of the slewing bearing 2, and there is a reducer 11 on the outside of the slewing bearing 2. The reducer On the top of 11 is an electric motor 12 connected to each other. The yaw transmission gear 10 of the reducer 11 meshes with the teeth 3 on the slewing support 2. The axis of the yaw transmission gear 10 is parallel to the center line of the slewing support 2; The inner edge of the slewing support 2 is provided with several bolts 13 along the circumferential direction of the slewing support 2, and the axes of the bolts 13 are also parallel to the center line of the slewing support 2; a rotation limit switch 6 and a position sensor are also arranged outside the slewing support 2 4. The gear 8 interconnected with the rotation limit switch 6 meshes with the teeth 3 on the slewing support 2 .

[0011] The rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com