Automatic control system of stirring turnover throwing vehicle for bar-shaped pool

An automatic control system and strip pool technology, applied in the direction of electrical program control, program control in sequence/logic controller, specific-purpose bioreactor/fermenter, etc., can solve the problem of reducing work efficiency and affecting the machine Operation and other problems, to ensure reliable operation, improve work efficiency, and solve the effect of uneven ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

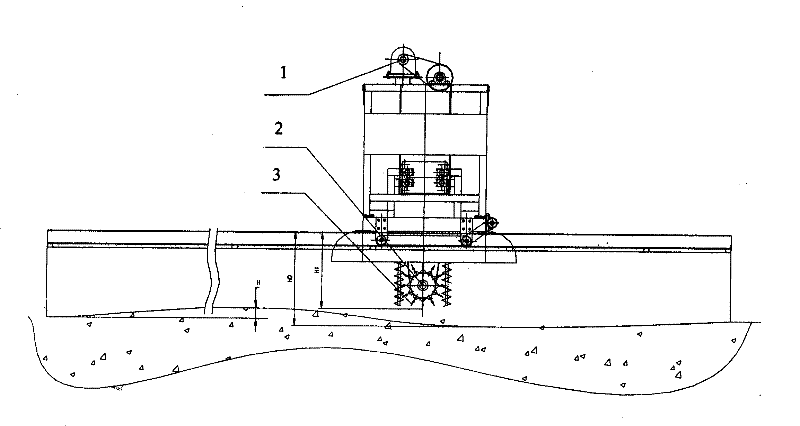

[0010] When the ground height h of the strip pool in the length direction is the maximum, it is the benchmark At this time, the height of the orbit from the reference ground is h 0 , the height between the stirring fin 1 and the track is h 1 , the height between the stirring fin and the ideal level ground is H, and the height difference between the uneven ground surface and the ideal level ground is ΔH 1 , the height meter between the stirring fin and the uneven ground surface is ΔH 2 , ΔH 2 =H-ΔH 1 .

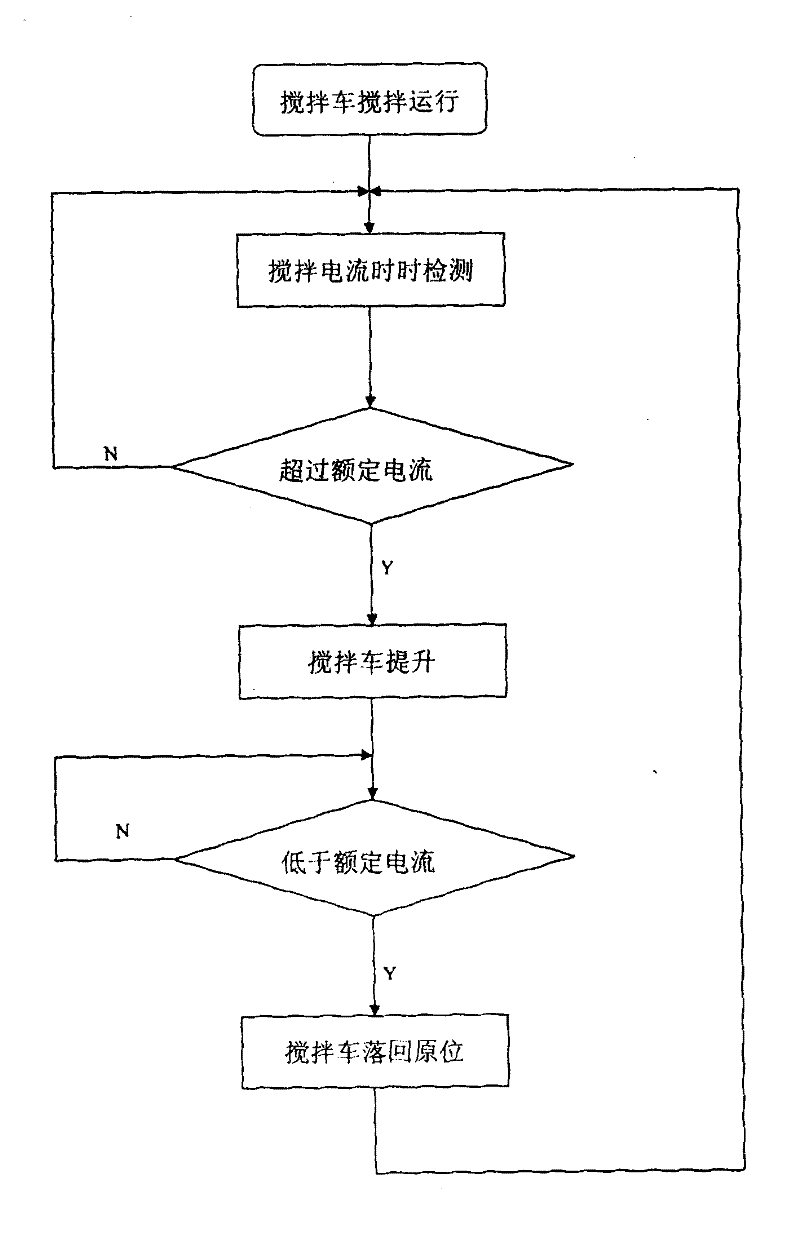

[0011] ①When 01 When ≤10mm, the stirring shaft 2 works at this height;

[0012] ② When ΔH 1 When >10mm, the stirring shaft 2 is automatically lifted by the lifting mechanism, and the lifting height is X mm. The X value is proportional to the change of the current, that is, ΔH 1 The larger the value, the higher the ground level, the greater the deformation of the stirring fins, the greater the stirring current, and the greater the lifting height X.

[0013] ③ When ΔH 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com