Butanone-water system cross-flow liquid-liquid extraction separation method

A separation method and water system technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of difficult separation of butanone-water system and difficulty in obtaining high-purity butanone products, and achieve obvious dehydration effect and production The effect of low cost and low energy consumption

Active Publication Date: 2010-11-10

JIANGSU YINGTIAN CHEM

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the production and purification process of methyl ethyl ketone, water is the main impurity, which must be separated and removed. However, due to the partial miscibility of methyl ethyl ketone and water at low temperature, azeotropes are formed during distillation, which brings difficulties to the separation of methyl ethyl ketone-water system. It is difficult to obtain high-purity methyl ethyl ketone by ordinary distillation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

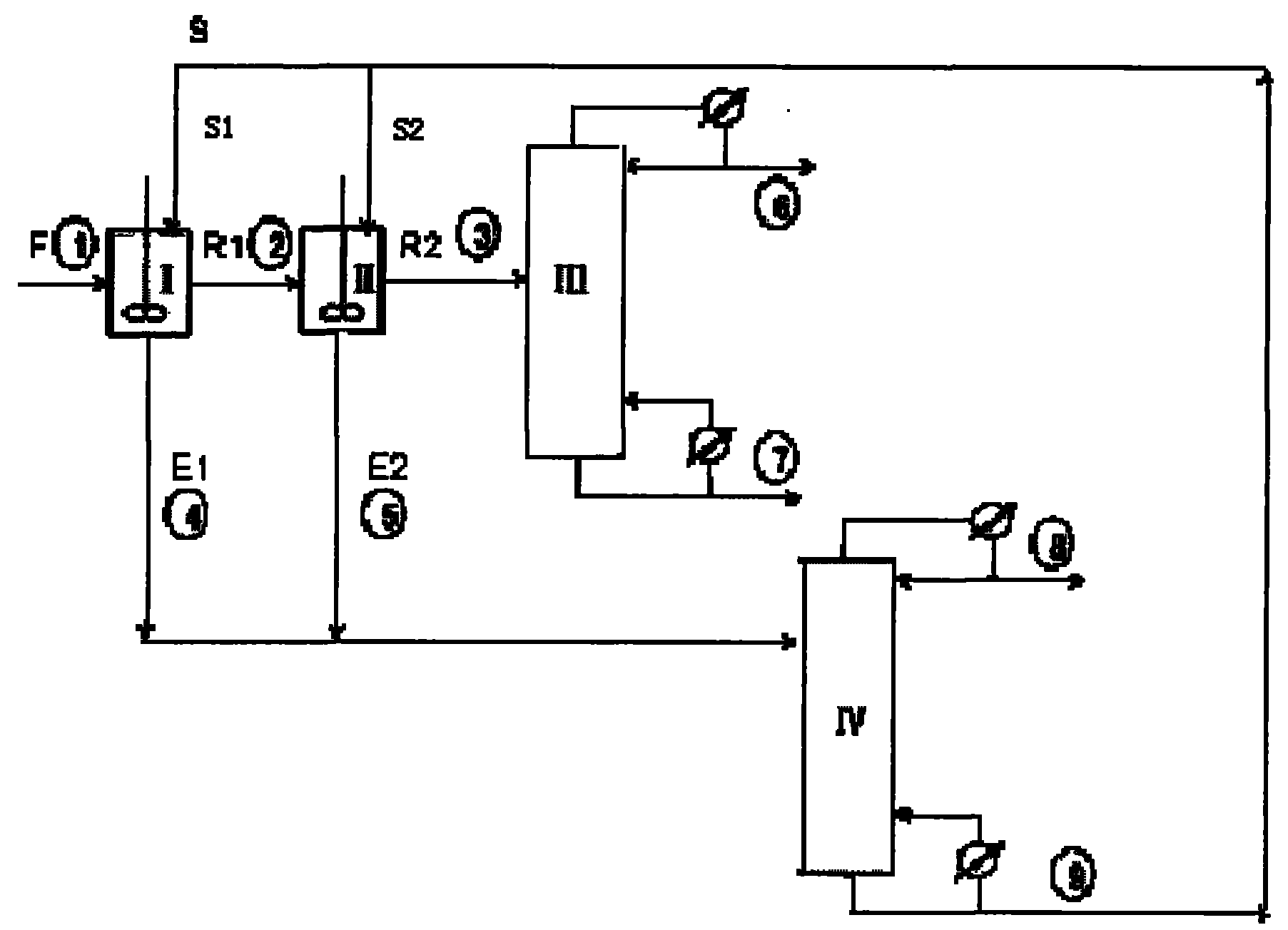

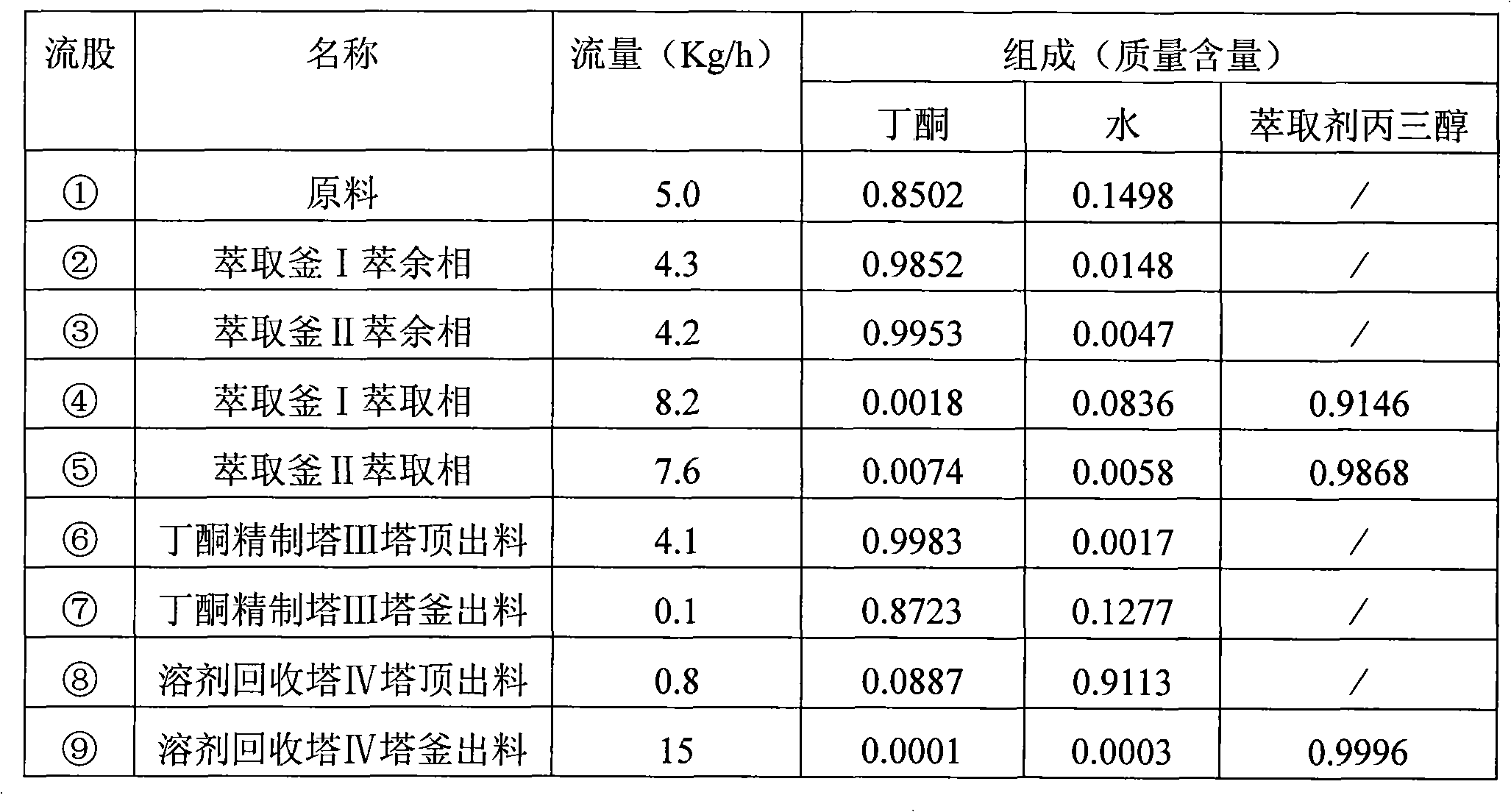

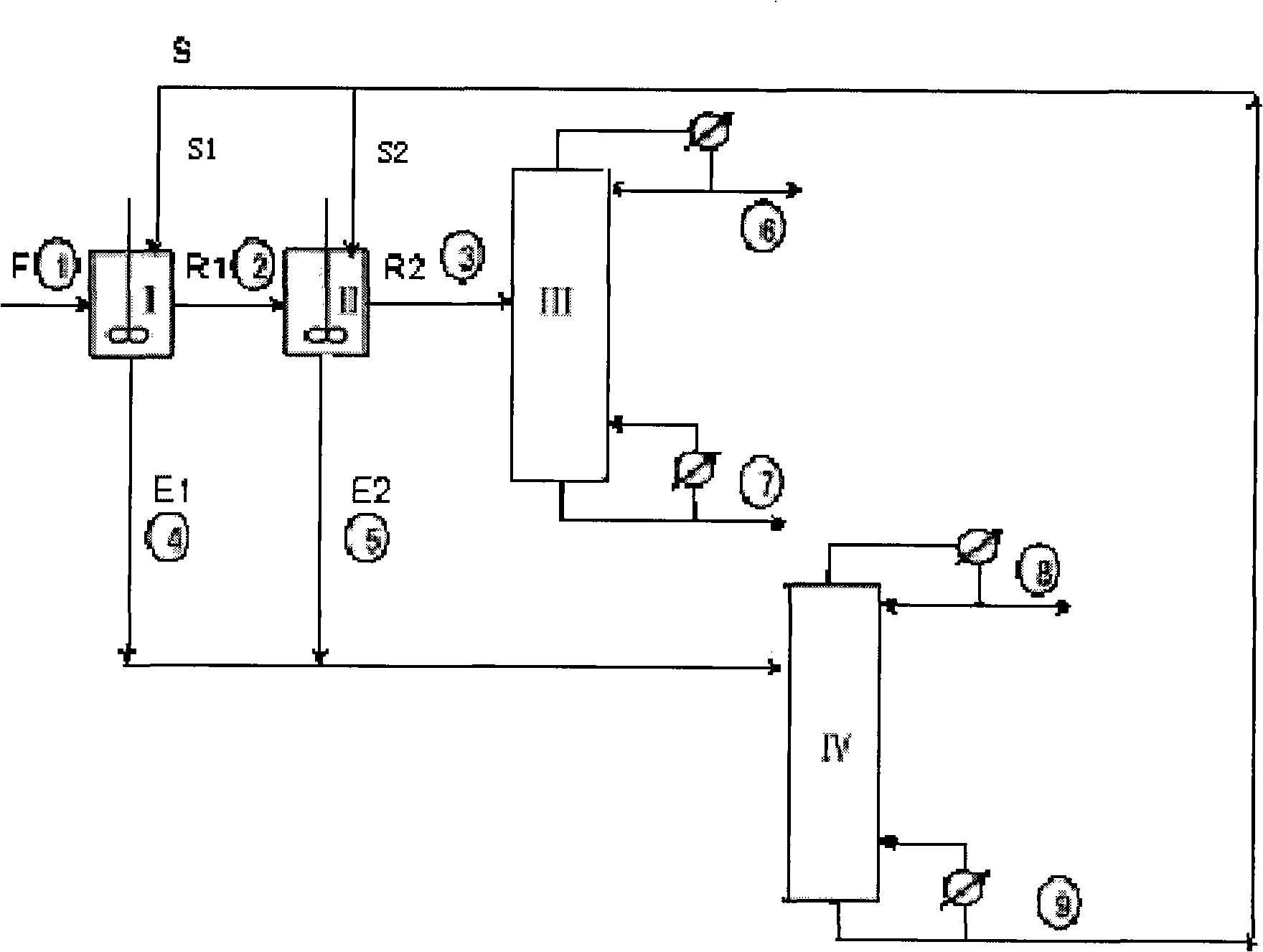

The invention relates to a cross-flow liquid extraction separation method for a butanone and water system, which is characterized by comprising the following steps that: a mixture of the butanone and the water is taken as a raw material, polylol is taken as an extractant, and the raw material and the extractant are adopted to carry out two-stage cross-flow liquid extraction to a butanone aqueous according to a certain proportion; after the mixed liquid is layered and separated, the residual extraction liquid contains the butanone with higher purity; a extraction phase is the extractant and the water; after the extraction phase is subjected to decompression, distillation and dehydration through a regeneration tower, the extractant is recycled. Compared with the prior distillation and azeotropic distillation method, the extraction separation method has more obvious dehydration effect, higher purity of products, higher recovery ratio and lower energy consumption. Meanwhile, the extractant in the whole process can be recycled, so production cost is lower, and a problem of polluting environment can be avoided.

Description

Butanone-water system cross-flow liquid-liquid extraction separation method technical field The invention relates to a chemical separation method, in particular to a cross-flow liquid-liquid extraction separation method of a methyl ethyl ketone-water system. Background technique Butanone is an important chemical raw material. It is a low-boiling organic solvent with excellent performance and ideal effect. It is widely used in oil refining, dyes, coatings, adhesives, medicines and lubricating oils. It can be used in plant extraction and azeotropic distillation, and has a wide range of applications. In recent years, its consumption has increased sharply in countries all over the world. In the production and purification process of methyl ethyl ketone, water is the main impurity, which must be separated and removed. However, due to the partial miscibility of methyl ethyl ketone and water at low temperature, azeotropes are formed during distillation, which brings difficulties ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07C49/10C07C45/80

Inventor 林军顾正桂冯佳佳

Owner JIANGSU YINGTIAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com