Method for preparing coal gas from molded coal

A technology of briquette and gas, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of increased resistance of the material layer in the furnace, difficulty in meeting enterprise requirements, and low calorific value of gas, so as to improve heat utilization rate and alleviate The effect of tight supply and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

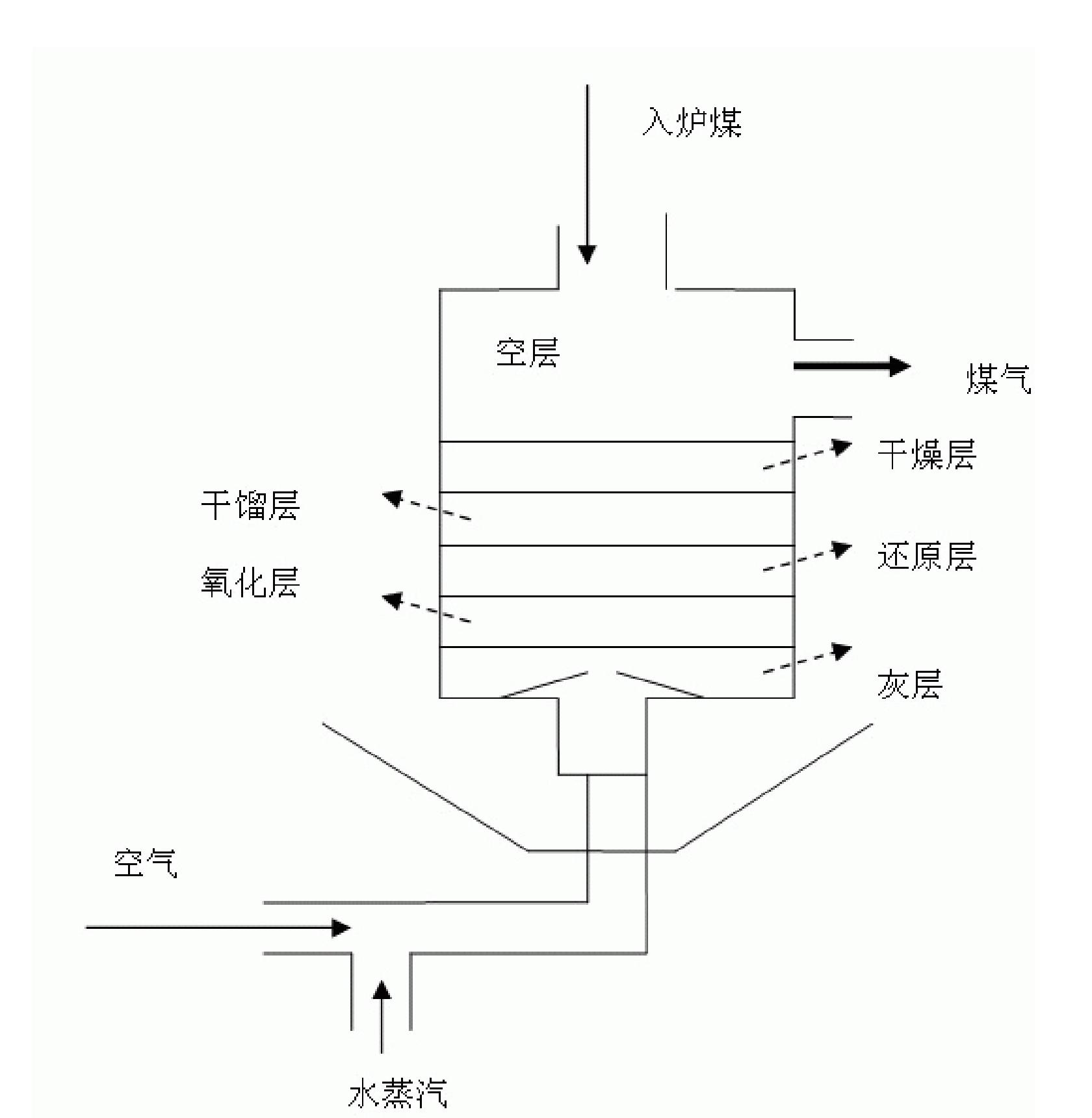

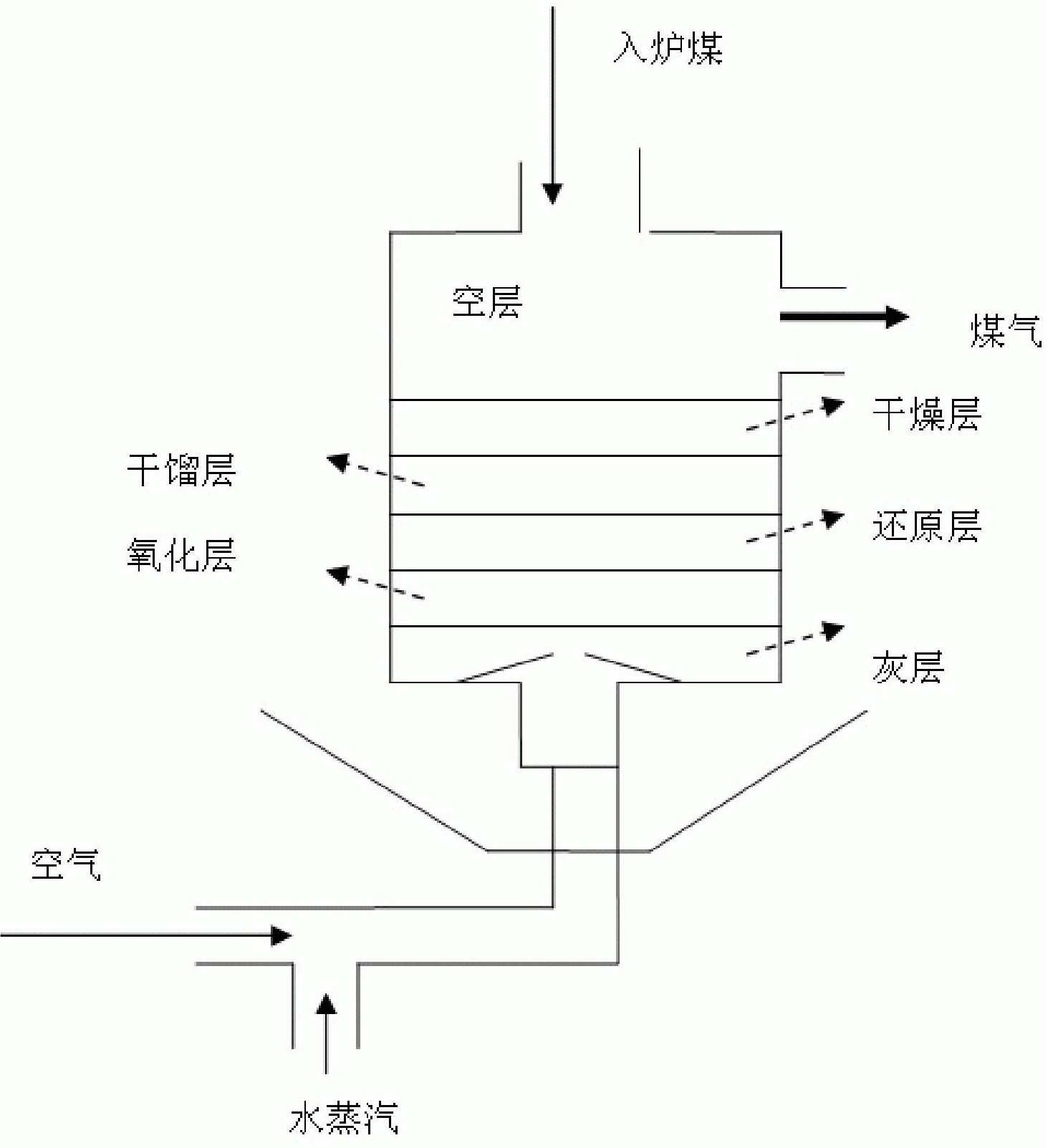

[0016] Embodiment 1 prepares coal gas with the method for coal gas preparation of the present invention

[0017] When coal briquettes are gasified, the thickness of each material layer is: ash layer 300mm, gasification layer 250mm, fuel preparation layer 500mm; the gasification agent used is obtained by mixing water vapor and air with an oxygen volume content of 26%, and the saturation temperature of the gasification agent is It is 65°C; the frequency of brazing measurement is once every 2 hours, and the temperature of gasification layer is 1000°C.

[0018] After measurement, the calorific value of the obtained gas is 6300Kj / Nm 3 .

Embodiment 2

[0019] Embodiment 2 prepares coal gas with the method for coal gas preparation of the present invention

[0020] When coal briquettes are gasified, the thickness of each material layer is: ash layer 400mm, gasification layer 280mm, fuel preparation layer 650mm; the gasification agent used is obtained by mixing water vapor and air with an oxygen volume content of 27%, and the saturation temperature of the gasification agent is It is 66°C; the frequency of brazing measurement is once every 2 hours, and the temperature of gasification layer is 1100°C.

[0021] After measurement, the calorific value of the obtained gas is 6500Kj / Nm 3 .

Embodiment 3

[0022] Embodiment 3 prepares coal gas with the method for coal gas preparation of the present invention

[0023] When the briquette is gasified, the thickness of each material layer is: ash layer 500mm, gasification layer 300mm, fuel preparation layer 800mm; the gasification agent used is obtained by mixing water vapor and air with an oxygen volume content of 28%, and the saturation temperature of the gasification agent is It is 67°C; the frequency of brazing measurement is once every 2 hours, and the gasification layer temperature is 1050-1150°C.

[0024] After measurement, the calorific value of the obtained gas reaches 6700Kj / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com