Composite gear oil additive

An oil additive and compound gear technology, which is applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of large amount of addition, high cost, complicated preparation process, etc., to reduce noise, low cost, and improve extreme pressure and anti-wear. The effect of temperature and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

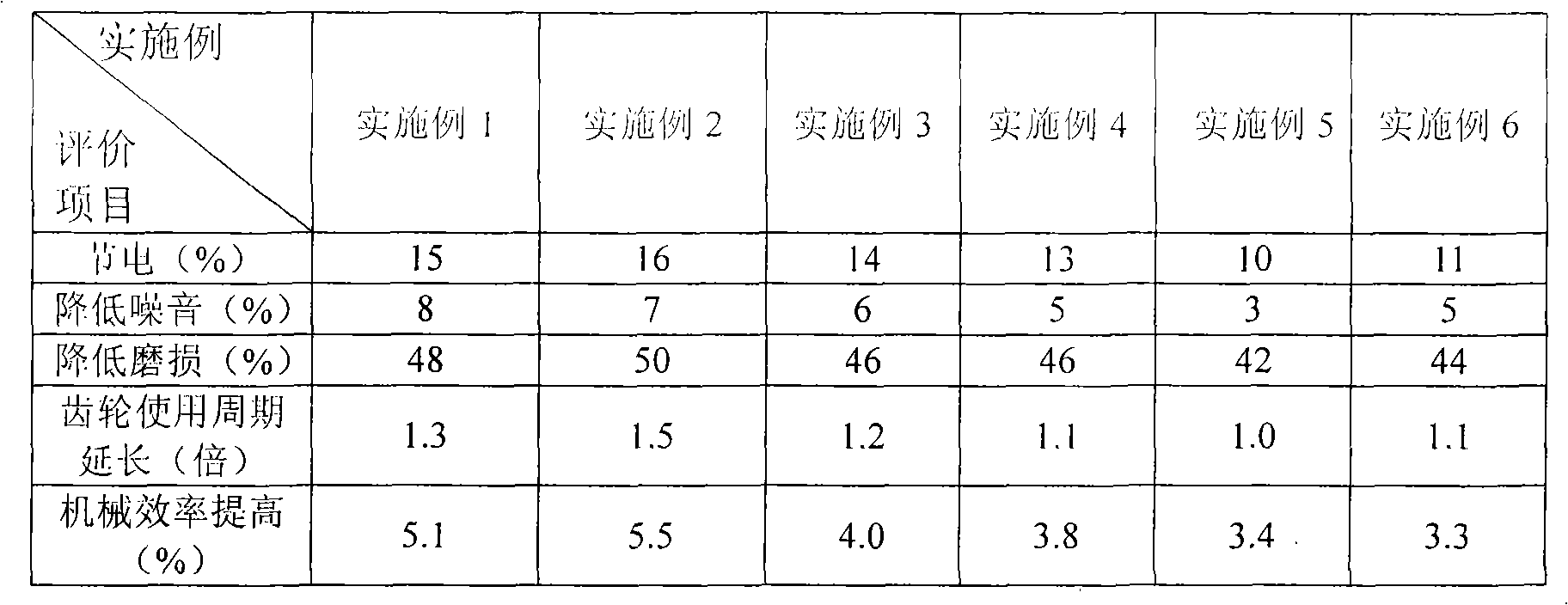

Examples

Embodiment 1

[0017] Add 12 parts of graphite, 12 parts of sodium metaborate, 8 parts of polyisobutylene succinimide, 50 parts of base oil 150SN, and 8 parts of 500SN into the emulsification kettle and raise the temperature to about 60°C, and disperse and emulsify for 2 hours;

[0018] The obtained product is pumped to the dehydration tank for heating, vacuumed and dehydrated under negative pressure, the heating temperature is controlled at about 66°C, the negative pressure is controlled at 0.08Mpa, and the time is 2 hours;

[0019] The obtained product was transported back to the emulsification tank, and 10 parts of polymethacrylate was added for emulsification and dispersion for 0.5 hours, and then pumped to a grinder for grinding for 2 hours;

[0020] The obtained product was sent to an ultrasonic vibration tank for ultrasonic vibration for 1 hour;

[0021] The obtained product is filtered through a filter to obtain the composite gear oil additive 1, and the filter diameter is controlled...

Embodiment 2

[0024] The following raw material proportions are adopted: 16 parts of graphite (same as Example 1), 9 parts of bis-succinimide, 15 parts of potassium metaborate, 46 parts of base oil 150SN, 6 parts of BS150, polymethacrylate and ethylene-propylene 8 parts of glue copolymer. Except for this, a composite gear oil additive 2 was obtained in the same manner as in Example 1.

Embodiment 3

[0026] The following raw material proportions are used: 20 parts of graphite, 7 parts of bis-succinimide, 2 parts of monosuccinimide, 13 parts of potassium triborate, 50 parts of base oil 500SN, and 8 parts of polymethacrylate. Here, the graphite is amorphous graphite with a purity of 99%, 85% by weight of particles with a particle size of 0.5 microns or less, and the maximum particle size is not more than 5 microns. Except for this, a composite gear oil additive 3 was obtained in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com