Superconductor component and its implantation process

A component and superconducting technology, which is applied in the process field of using metal powder materials as implanted aggregates, can solve the problems of high processing cost, soft structure, and performance decline, and achieve low production cost, easy thickness, and easy mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical characteristics of the present invention will be further described in conjunction with the following examples. The examples are only representative examples and are not intended to limit the scope of the present invention. The best understanding can be obtained through the accompanying drawings in conjunction with the following detailed description.

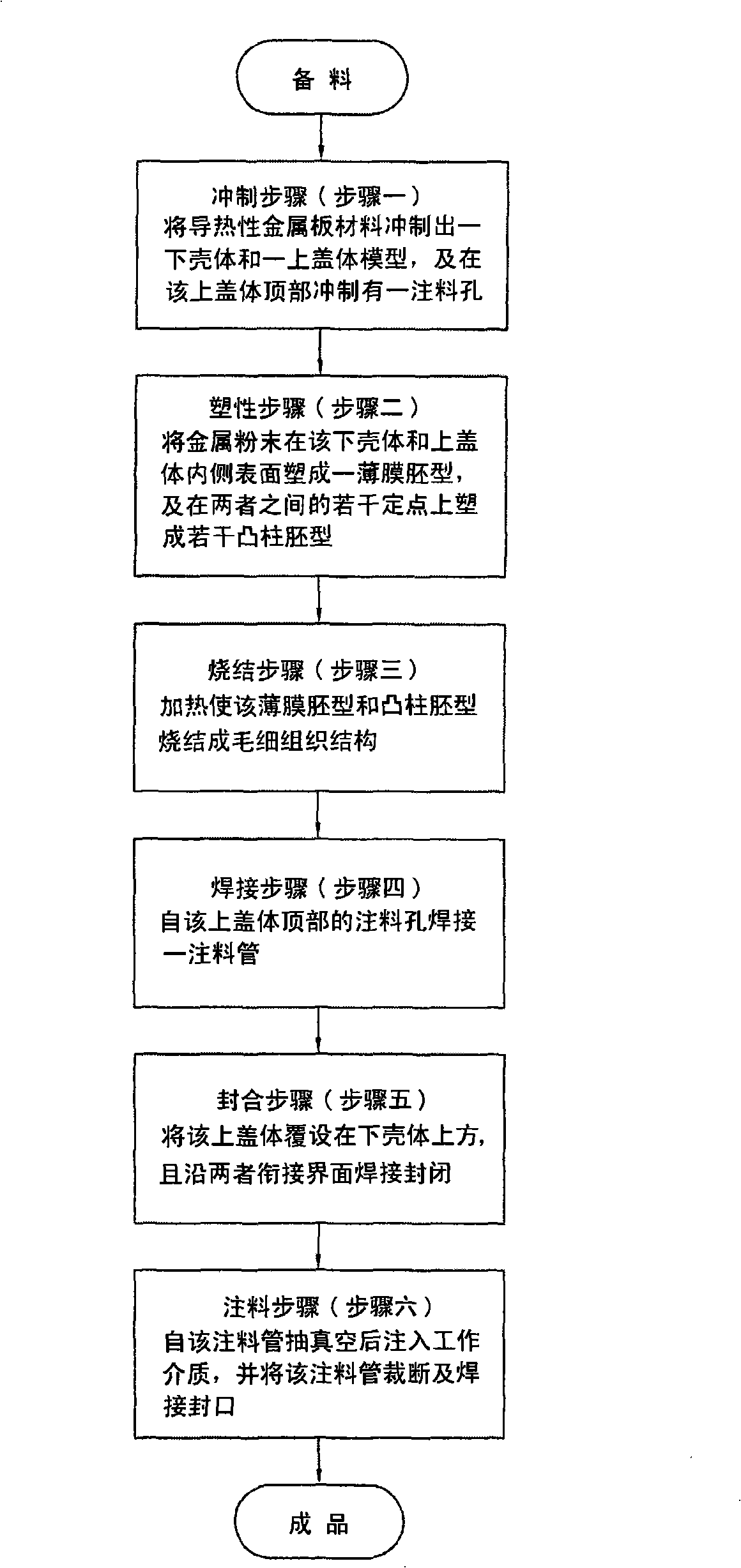

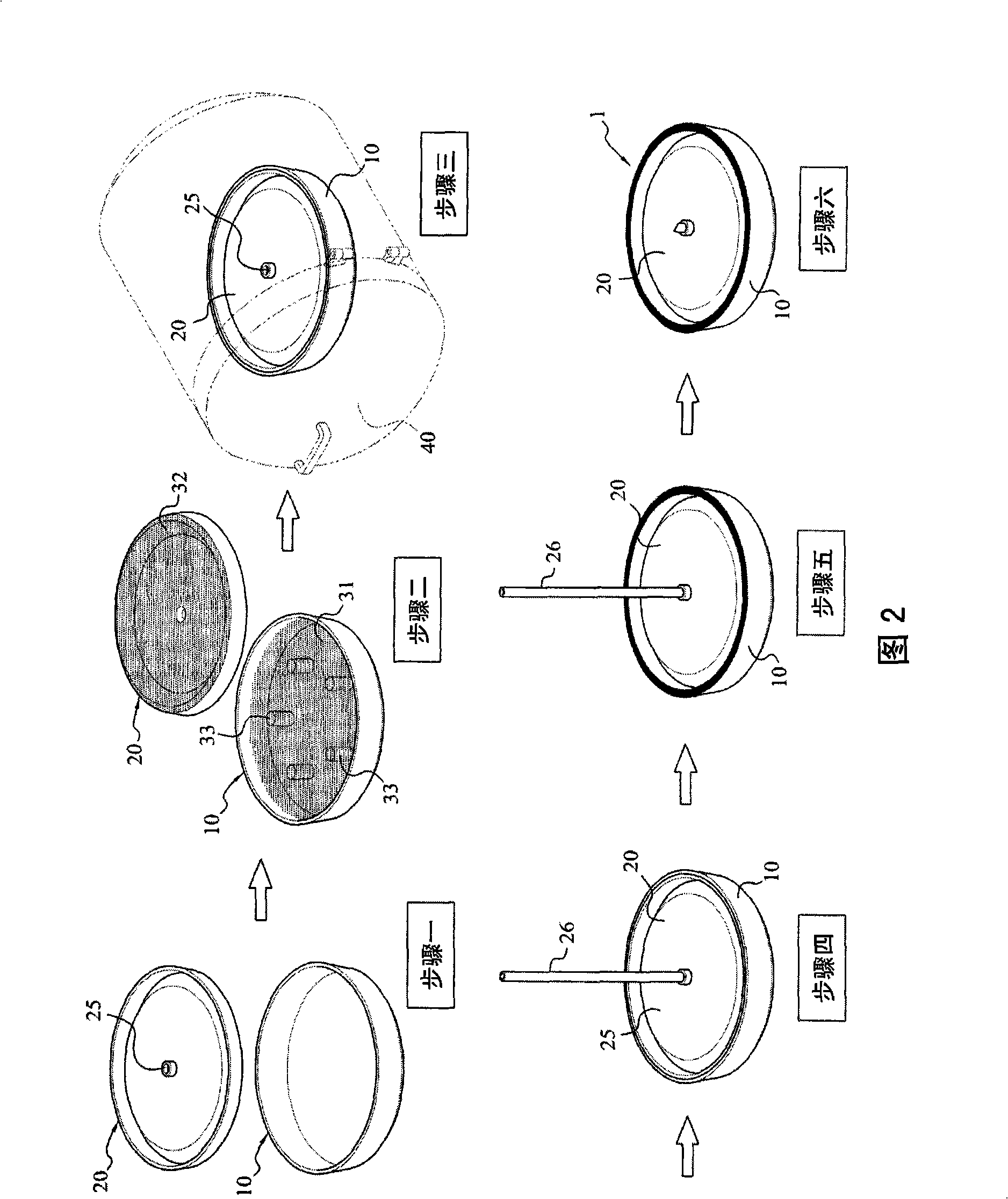

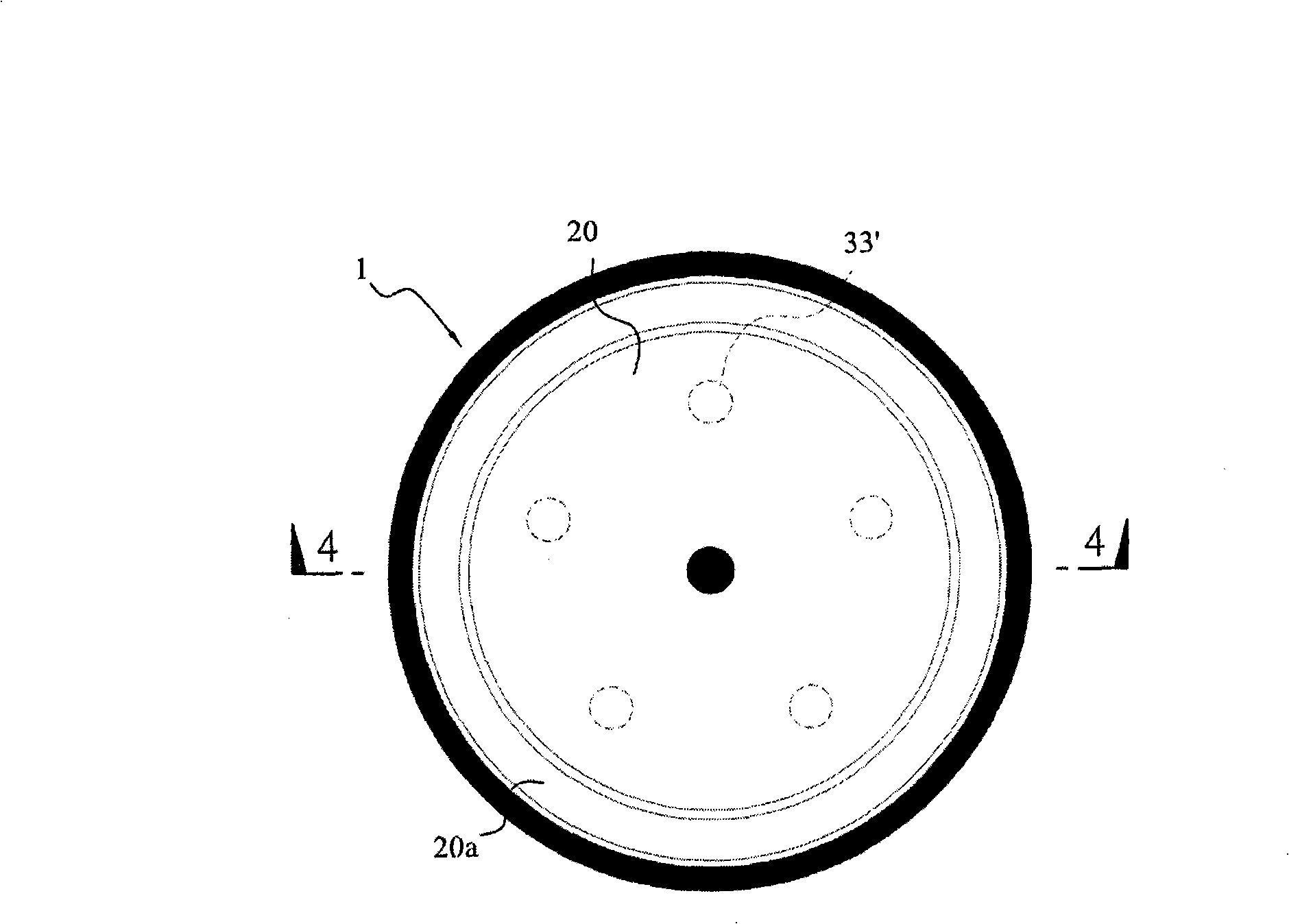

[0022] First, please refer to figure 1 With reference to Fig. 2, according to the process of implanting superconducting component 1 into aggregate of the present invention, it at least includes the following steps:

[0023] Punching step: Prepare thermally conductive metal plate materials, such as copper plates or nickel plates, etc., and punch out a lower shell 10 and an upper cover 20 model, which can jointly form a cavity, and in this A filling hole 25 is punched on the top of the upper cover body 20 (as shown in step 1 of FIG. 2 ).

[0024] Molding step: After mixing metal powder such as copper or nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com